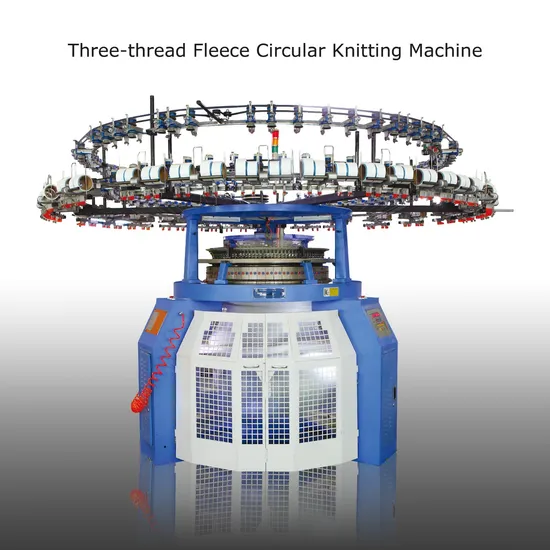

Three-Thread Fleece Circular Knitting Machine Weft Knitting Machine

| US$18,000.00-30,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

RS-D/W3

Knitting Product Type

Sweater

Knitting Style

Weft

Knitting Method

Single

Needle Style

Latch Needle

Needle Bar Style

Circular Knitting Machine

Computerized

Computerized

Condition

New

After-sales Service

Installation, Operation Training

Cylinder Diameter

30"~34"

Gauge

12g~44G

Feeders

78f~102f

Origin

China

HS Code

84471200

Production Capacity

100 Sets Per Month

Product Description

Type:

This is a single jersey knitting machine for three-thread fleece.

Features:

It has all the features of three-thread fleece knitting machine, with perfect plating of binding and ground thread.

This machine is also highly flexible, if desired, it can be easily converted into regular single jersey machine, thereby it can knits all single jersey structures.

The heart parts of the machine.

General: Single jersey machine with 3.0 feeders per diameter inch capable to knit three-thread fleece, with or without Elastane Perfect plating of binding and ground yarn Possibility to convert the machine for the production of single jersey plain and structures Optional central adjustment lifting system, easy to control fabric weight

Frame: Standard frame for 500 mm fabric rolls High frame leg for bigger fabric rolls optional Standard Chinese brand oiler and inverter Memminger oiler optional Toshiba inverter optional

Needles: Groz needles Standard 2 needle tracks

Cam parts: Standard steel cam box Aluminum cam box optional, for great heat dissipation property and light weight Exchange cam for 3 positions in KNIT-TUCK-MISS Individual stitch length adjustment

Yarn feeding: Yarn creel with yarn pipe MPF, give positive feed to the machine Standard Elastane feeder for all feeds Memminger yarn feeder optional Ceramic yarn carriers Product Parameters

Technical data:

| Machine Type | Single Jersey |

| Function Device | Three-thread Fleecy |

| Cylinder Diameter | 30"~34" |

| Machine Gauge | 12G~44G |

| Feeders | 78F~102F |

Product Application

Structures:

This machine can knit a wide variety of single jersey three-thread fleecy structures.

Application:

Applied in multiple fields such as sports & leisure, outerwear etc.

Our Advantages

High Manufacturing Capacity:

Annual production of 1500 ~ 2000 circular knitting machines and related accessories.

High Quality:

We have our own product research and development center, and equipped with various advanced CNC processing equipment from Germany, Japan and other places, all the core machine components are processed under CAD/CAM to ensure the product quality.

Competitive Price:

Most of the machine components are made by ourself, and have lower cost compare to purchase components from other factories.

Quality Service:

Our professional team provides pre-sales and after-sales services such as product consultation, technical guidance, installation services, and operation training.

Production Equipment

Core Component Processing

>> Customized Programmable High accuracy and uniformity Temperature And Humidity lab Test Chamber Price

>> Multi-Purpose 10L Laboratory Mixer Apply for Chemical Text Industry

>> Quality Reliable Impact Wet Clay Crusher PF1316 Quotation for Sale

>> Greetmed emergency travel economic portable male adult disposable 2000ml urine bag with belt

>> China Factory Produced Hydraulic Truck Unloading Lift Ramp

>> for Volvo S60 2.0t, Automobile Generator 36001105

>> Custom Logo Knitted Winter Beanie Hats for Men and Women

>> 100% water proof motrozied aluminum pergola price bioclimatic aluminum gazebo

>> 2 Cavity Mold Hot Runner for Injection Mold

>> Door to Ddor DDP Railway Freight Forwarder China to Estonia Ireland

>> CNC Milling Machining Center Gmc1213 Heavy Duty Gantry Center

>> Hot Water Heating System Expansion Tanks with Removable Bladder Membrane

>> Aluminum Hexagon Frame Handle Lock Tempered Glass Double Hung Window

>> Semi Automatic Motorized Single Hole Drilling Machine (JS180)

>> PP Plastic Winding Pipe Production Line Hose Winding Machine Plastic Pipe Winder Machine

>> Brand-New Made in China High Quality 4-Seater Golf Cart Travel Electric Golf Car

>> Badminton Racket Training Racket Aluminum Alloy One Ultra Light High Elastic Play Double Entertainment Training

>> Modern Wood Rocking Chair with Comfortable Feeling

>> Compact and Efficient Wire EDM Solution Dk7763

>> Rechargeable Lithium Heavy Duty Cordless 600n. M Torque Brushless Electric Impact Wrench

>> Lithium Battery Portable Multi Function Washing Machine High Pressure Water Sprayer

>> Fujixun Factory Commerical Mra Mrl Goods Cargo Passenger Elevators Home Villa Elevator Lift Panoramic Bed Hospital Stretcher Elevator Car Lifts

>> Solar Road Safety LED All in One Light Three Colors Red Green Yellow Automatic System Solution Warning Signal Traffic Light

>> Customized 3 Cells Clear Acrylic Storage Box with Lid Seprately Rectangle Acrylic Box

>> Tungsten Bar - High-Precision Custom Tungsten Metal Bar, Stock Availability, Heat Treatment, DHL Delivery, T/T Payment, CE Certified, ISO Certified

>> Custom Made OEM Precision CNC Turning Service Aluminum Parts Customized Stainless Steel CNC Machining Products

>> X6M Body kits for BMW X6 E71 body kit for BMW X6M HMY style 2008-2014 Year

>> AC 22kw Fast Charging EV Car Charger

>> Premium Quality Pig Equipment and Essential Accessories for Farmers

>> Zk5140c Drilling Tapping Machine 40mm Hole CNC Drilling Machine