High Capacity Large Wire Drawing Machine for Copper Wire with Annealer

| US$213,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

HH-D-350

Type

Horizontal Metal Drawing Machine

Usage

Wire, Prestressed Steel Wire

Metal Material

Copper

Outlet Diameter

1.0-2.7mm

Max.Inlet Wire Dia.

3.6mm

Block Dia.

500mm

Max. Number of Block

10

Certification

RoHS, ISO

Condition

New

Wire Size

2.6-3.5mm

Wire Finished Diameter

1.0-2.7mm

Max Dies No.

9

Power Supply

380V/50/60Hz

Drawing Motor

AC 80 Kw

Dimensions

14*3.5*4 M

Weight

7000 Kg

Transport Package

Plastic Package

Specification

CE ISO SGS

Trademark

HOOHA

Origin

Dongguan

HS Code

8463102000

Production Capacity

5 Sets/Month

Product Description

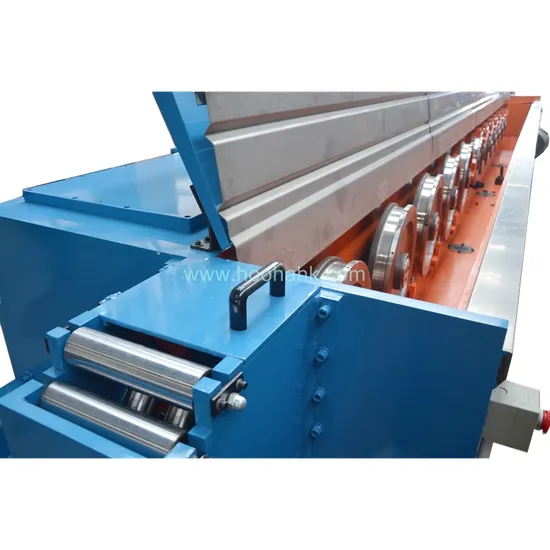

High Capacity Large Wire Drawing Machine for Copper Wire with Annealer ApplicationThe production line is applicable for 2.6-3.5mm copper wire, drawn out to 1.0-2.76mm wire. Along with annealer, the finished conductor wire with annealing process can be used for next process stranding or extrusion.

Youtube Video Reference: https://hoohaco.en.made-in-china.com

General Parameters

Main Components

1. Drawing Machine

| 1 | Inlet Dia.(mm) | 3mm |

| 2 | Outlet Dia.(mm) | 2.5~1mm |

| 3 | Mechanics Speed(m/min) | Max 1200 |

| 4 | Capstan Dia.(mm) | 350mm |

| 5 | No. of Dies(Channel) | 9 |

| 6 | Dies Outlet Size(mm) | 25mm × 8 - 12mm (thickness) |

| 7 | Mechanics Elongation (%) | By the dies from the 1st to 8th, 25% by the 9th die, 16.7% |

| 9 | Main Motor Power(KW) | AC45 |

| 7 | Constant Speed Capstan Motor (KW) | AC11 |

| 10 | Drawing Coolant Mode | Full Immersion |

| 11 | Dimension(mm)L×W×H | 4500×3000×3500 |

| 12 | Machine Net Weight(kg) | About 4000 |

2. Annealing Machine

| 1 | Wire Size range of Annealing(mm) | 1~2.5 |

| 2 | Annealing Mode | Contact mode DC annealing |

| 3 | Max. annealing DC current (A) | 2500 |

| 4 | Max. annealing DC voltage (V) | 57 |

| 5 | Steam consumption by annealing | 10 - 12kg/h, 0.2 - 0.3MPa |

| 6 | Air consumption by annealing | 20 - 30 m3/h, 0.4 - 0.6MPa |

| 7 | Annealing capacity | Max. 150 KVA |

| 8 | Dimension(mm) L×W×H | 3500×1200×2000 |

| 9 | Machine Net Weight(kg) | About 3800 |

3. Take-up Machine

| 1 | Take-up control | Weight type tension bar |

| 2 | Take-up volume | 500kg, max |

| 3 | Size of Take up | Φ630mm |

| 4 | Take Up Motor(kw) | AC 11 |

| 5 | Transport Reel Motor(kw) | 0.75 |

| 6 | Dimension(mm) L×W×H | 1800×2000×2500 |

| 7 | Machine Net Weight(kg) | About 2000 |

Drawings

Packaging & Shipping

Streatchable PE film wrapped, wooden frame packed, loaded into container for shipping. Special packaging way as per discussed.

Our Advantages

Our Focus

1.Quality, our engineers work with service colleagues to learn more about customer feedback and improve our machines accordingly.

2.Customers' comfortable purchasing experience.We pay attention to the actual needs of customers, and hope to bring customers high-efficiency products and intimate service, our services cover pre-sales and after-sales, committed to let customers save time and cost, and reduce worries

3.Customers' success.We not only focus on the sales of products, but also pay attention to the development of our customers. We pursue growing together with customers by providing long-term support and suggestions to help them achieve success.

4.Supply more environmentally friendly products.

5.Give back to the community and help more people.

FAQ

Q1:What is your main brands for the electrical and mechanical parts?

A:Oversea famous brand such as German siemens motor, Japanese nsk bearing and yaskawa inverter etc.

Q2:What is your difference with other suppliers?

A:What we could offer to other customer is not only the machine itself, also we could offer: factory design, production process

design , QC control, talent training, assist machine and raw material offering .

Q3:What's the payment terms?

A:T/T,30% deposit and 70% balance before delivery, can be negotiable also.

Q4:How long the guarantee ?

A: One year and charge for repair in the whole life.

Q5: Do you have a video to show the machine running ?

A. Yes , we have,our youtube channel : tiezhong chi.

>> Factory Selling Good Price High-Speed Mixer for Mixing of PVC Raw Materials

>> Aminoplus 100% Water Soluble Fertilizer Animal Source Amino Acid

>> 60t Fully Continuous Waste Tyre Pyrolysis for Diesel Oil

>> 7 Years Warranty CE ETL Approved LED Canopy Light 40W 60W 80W 100W High Lumen Output IP65waterproof Gas Station Light

>> Lab Supplies Disposable Universal Transparent 20UL Pipette Tips with Filter

>> Oturn Machinery Sy1200 Horizontal Turning Machine with GSK/Siemens/Fanuc/Mitsubishi Control System CNC Lathe

>> Manufacture Completely Automatic Chicken Cage for Layers Broilers Brood Modern Poultry Farm Equipment H Type 8 Tier 5 Row Capcity 100, 000 Chickens

>> China Low Cost ultrasonic Water Level Depth Meter Gauge

>> 1 ton 5 CBM mini refrigeration van truck for sale

>> Wholesale Disposable Take Away Food Grade Customized Printing High Quality 7oz 8oz 12oz 16oz 20oz Custom Printed Coffee Paper Cup Forming Machine

>> 12kv Gas-Insulated Circuit Breaker and Load Switch for Switchgear

>> China Manufacturer Heavy Custom Duty HDPE 1200X1000 Large Logistic Racking Industrial Rackable Warehouse Storage Reusable Euro Stackable Plastic Pallets

>> JYD customized sunroom enclosures sunroom prefabricated aluminum triangular conservatorysunrooms glass houses

>> Hot Sale Folding Wall Bed Spring Mechansim Murphy Bed Hardware Next Bed with Slat System

>> Pet Bottle Wahsing Recycling/ Waste Pet Bottle Recycling Washing Line From China

>> Leke Vr Franchise Simulator Game Machine Shooting CS Vr Battle Virtual Reality Gaming Equipment Arcade Game Machines Amusement Park Games Machines

>> Waterdrop Shaped Glove Washing Face Sponge Cleansing Sponge Facial

>> Customised Gym sports gymnastics 18 inch fitness yoga column set hollow massage yoga foam roller

>> Convenyor Type PU Pouring Machine for Safety Shoes with 40/60/80 Station AC Control system

>> Holo All in One Air Cooling Portable Conveyor Belt Splice Press

>> a-Zen Hot Sale Needle Cover for Warp Knitting Machine

>> 12 Pieces Plastic Pirate Telescopes Pirate Theme Party Telescopes

>> Medical Digital X-ray Photography Dystem Dr X Ray Machine

>> High Quality Fresh Ya Pears Wholesale

>> Single Column Vertical Lathe 700 Rotation Flywheel Housing Rim Special CNC Vertical Lathe

>> Large Capacity Portable Sakura Cosmetic Bag Travel and Daily Use Fashion Travel Cosmetic Bag

>> Interconnected Smoke & Carbon Monoxide Detector with 10 Year Battery Interlinked Alarm

>> Spz-3r Dry Refractory Gunning Machine Concrete Spraying Shotcrete Gunite Machine

>> CNC PCD Tips Saw Blade Sharpening Machine Knife Grinder Tooth Grinding Equipment

>> 1.8m 1.95m solid carbon fiber jigging fishing rod,detachable handle 1.5 sections PE1-3 2-4