Hinge Drilling Machine Woodworking Drilling Machine Panel Furniture Hinge Drilling Machine

| US$6,180.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

Z-6X

Controlling Mode

Artificial

Automatic Grade

Semiautomatic

Precision

High Precision

Certification

CE, ISO

Energy Saving

Energy Saving

Warranty

1 Year

Customized

Customized

Condition

New

After-sales Service

One Year

Product Name

Hole Drilling Machine

Application

Drilling Wood Panel Holes

Function

Wooden Pin Hole Drilling Machine

Usage

Drilling Wood Hole

Voltage

AC380V/50Hz

Power

10.8kw

Spindle Speed

2880r/Min

Air Source Pressure

0.6-0.8MPa

Number of Spindles

6

Transport Package

Wooden Box

Specification

3300x1000x1100mm

Origin

China

Production Capacity

100sets/Month

Product Description

Product ParametersDownhole Hinge Drilling Machine:

1.Thickened double guide rails:The wood boring machine has two rails to ensure the precise movement and adjustment of the vertical axis, punching without shaking, stable performance.

2.Pure copper motor:Powerful power, stable output, good heat dissipation, motor up and down, using precision guide rails to slide.

3.The power-off protection technology can protect the internal components of the projector, prolong the service life, and prevent instant damage.

4.Limiting column flange plus scale, adjustable hole depth, vertical drilling without breakage, smooth incision.

5.Thickened positioning baffle, standard with precise scale, more accurate positioning by ruler.

6.Cylinder pressing device Position, tightly press the plate, the plate is stable and does not deviate during operation, preventing wrong operation.

7.High-quality drill bag:The internal gear bearing is made of high-hardness wear-resistant metal, wear-resistant and impact-resistant, reduces vibration and noise, has high hole depth accuracy and stable operation, and one-time molding.

8.Dust suction device:Connect the vacuum hose, vacuum inlet, efficient vacuuming, easy to operate.

9.Control panel:Independent control button, clear marking, convenient and fast.

10.Multi-head work:Separate button, the drill position can be adjusted separately, multiple hinge holes of the door panel are formed in one go.

11.Foot control, safe and labor-saving, easy to operate.

| Model | Voltage | Power | Spindle speed | Air source pressure | Number of spindles |

| Z-1X | AC380V/50HZ | 1.5KW | 2870r/min | 0.5-0.7Mpa | 1 |

| Z-2X | 3.6KW | 2880r/min | 0.6-0.8Mpa | 2 | |

| Z-4X | 7.2KW | 2880r/min | 0.6-0.8Mpa | 4 | |

| Z-5X | 9KW | 2880r/min | 0.6-0.8Mpa | 5 | |

| Z-6X | 10.8KW | 2880r/min | 0.6-0.8Mpa | 6 |

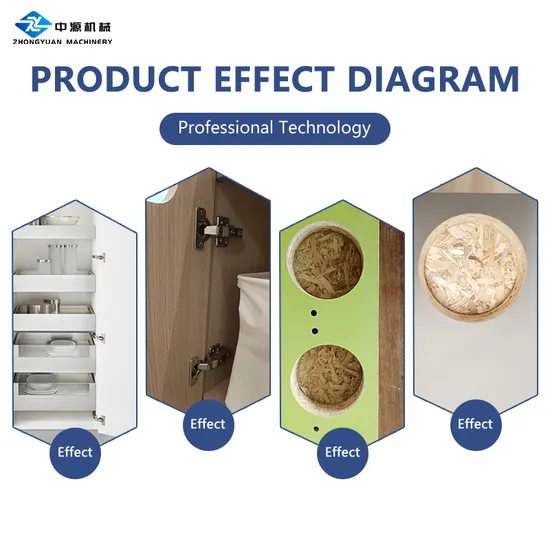

Detailed Photos

Product Application

Company Profile

Certifications

FAQ

Q1: I already have an edge banding machine and I would like a trimming machine. Do you have any recommendations?

A: Yes, we have a matching trimming machine. You can choose the product that suits you according to your actual production needs. Of course, we will also ask you some questions, such as plate size, plate thickness, equipment voltage, number of workers, and so on. With so many types of products, there is always one that is suitable for you.

Q2: Can your edge banding machine use PUR adhesive?

A: PUR glue has high requirements for glue pots. We recommend using models such as F14620-3700-3350 for up glue pots, depending on your specific needs.

Q3: Are you a factory or a trader?

A: We are a 20 year source production factory with rich production experience and a total of 8000+customers. We can provide you with thoughtful and accurate after-sales service.

Q4: How should I make the payment?

A: Firstly, you will pay a 50% deposit as a prepayment, and then we will start producing the equipment. After the equipment is completed, I will send you photos and videos, and you can make the remaining payment. After receiving all the payment, we will arrange for the fastest container to ship to you. You will receive the equipment soon, and I will arrange professional technicians to coordinate with you regarding installation issues.

Q5: How long is the delivery time?

A: Conventional equipment takes 10-12 days, customized voltage or other parameters take around 30-45 days.

>> Silicone Cosmetic Brush Case Container Silicone Cosmetic Brush Travel Hand Pouch

>> Multiple Units in Stock Used Truck Mounted Concrete Pump 56m Zoommlion 2021 with Cheap Price

>> HC-R010 Vet Operation Instrument Hydraumatic Surgical Operating Table Manual Veterinary Operation Bed for Animals

>> double tempered glass black color garage door panels with German motor other doors

>> Eddy Current Separator Non Ferrous Metal Separator Ferrous Magnetic Separator Waste Recycling Machine

>> Factory Custom OEM CNC Services Stainless Steel Spring Clips Sheet Metal Stamping Parts

>> Reliable Mercedes-Benz Pump Truck for Efficient Material Transport 4141 8X4

>> Factory Customized 8-Channel Backpack Anti-Drone Protection Device with Optional Frequency of 300-6GHz Omni Antenna Built-in Battery GaN Drone Jammer Module

>> Aluminum Stainless Steel Iron Metal Copper Titanium Custom Precision CNC Machining Turning Milling Forging Prototyping Die-Casting Gear Auto Bicycle Spare Part

>> China Machinery Precision M3 M4 M5 M6 M8 M10 M12 M14 Stainless Steel Bearing Bush Nut for Industrial Equipment CNC Turning Parts

>> High Speed and High Precision Wire Rope Drive Grinding Machine

>> Eaa Air Spring, Air Suspensio, Air Bags E8050 for Hendrickson Turck

>> 200 Liter 220L Double Ring Oil Chemical Drum Tank Making Machine Open-Top Drum Plastic Bucket Extrusion Blow Molding Machine

>> High-Tech Advanced Disc Centrifuge for Separating Animal Cottonseed Vegetable Oil on Sales

>> Fully Automatic Independent Research and Development System Electric Press Brake

>> FRP Flange Automatic Machine Made Instead of Hand Made

>> Hot Sale Used Excavator Cat 336D High Quality Hydraulic Crawler Excavator Usada Excavadora

>> Manual Pipe Cutting Machine Pipe Feeding- Reducing Production Line

>> Heavy Duty Conventional Lathe Cwa61160 Machining Max. Weigth of Workpiece 8000kg

>> Kangton 900W 300nm Electric Socket Wrench Set

>> 3-12X40 Llluminated Sniper Riflescope Optic Riflescopes Hunting

>> Hydraulic Head & Rotor 7123-340u #7123340u 4/9r for Delphi Cav Dpa Lucas Pump

>> Aluminum Door and Window Cutting Machine Heavy Duty High Efficiency CNC Angle Cutting Saw

>> Metal gypsum board access panel/aluminum ceiling access panel

>> Aro Micro Plastic Aodd Membrane Pneumatic Electric Air Operated Double Diaphragm Pump

>> Pure C11000 T2 Copper Busbar for Conductive

>> Lightweight Customized GRP Products with Exceptional Corrosion Resistance

>> Beryllium Copper C17200 Price Round Bar Rod Strips Plate

>> PP HDPE Pipe/Bottle Granulator for PP Hard Material Recycling Machine Plastic Recycle Machine

>> Outdoor Waterproof IP66 50W 100W 150W 200W Street Light