China Silicon Wafer Small Single-Side Grinding and Polishing Machine

| US$8,000.00-20,000.00 | 1 Piece (MOQ) |

Basic Info.

Type

Surface Grinding Machine

Processing Object

Flat Workpieces

Abrasives

Grinding Wheel

Controlling Mode

PLC

Automatic Grade

Semiautomatic

Cylindrical Grinder Type

Surface Grinding Machine

Precision

High Precision

Certification

ISO 9001

Condition

New

Power Source

Electricity

Disc(Wheel) Type

Grinding Disc

Working Style

Grain

Variable Speed

with Variable Speed

Disc Diameter

Φ460 mm

Service

Oversea Setup & After-Sale Avalaible

Class

Single Plate

Process Station

3

Pressure Source

Pneumatic or Weight Block

Abrasive

Slurry

Weight

1000kg

Transport Package

Wood Crate

Trademark

PONDA

Origin

China

Production Capacity

500 Unit/Year

Product Description

Why Ponda?Ponda has profound experience of lapping, polishing and thinning. We heretofore supplied more than 60, 000 lapping process solutions and appliances over the industries of machinery, electronic, aerospace, aviation, automotive, atomic energy, optics; the substances of metal, SiC wafer, ceramics, glass, industrial sapphire, plastics, and any other composites.

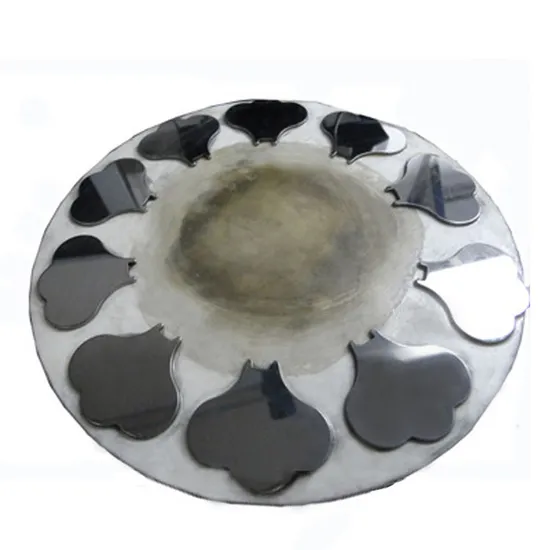

Products Show

High precision grinding machine equipment principle:

1. The grinding machine is a precision grinding and polishing equipment. The grinding and polishing materials are placed on the grinding disc, the grinding disc rotates against the clock, the correction wheel drives the workpiece to rotate, the gravity pressure is applied to the workpiece, and the workpiece and the grinding disc are subjected to relative running friction to achieve the purpose of grinding and polishing.

2. The disc repairing machine uses the hydraulic suspended guide rail to move back and forth, and the diamond shaving knife trims the grinding disc precisely, so that the grinding disc gets precise flatness.

SPECIFICATION

| Standard Specification | |||||||

| Machine Model | FD3803 | FD4603 | FD6103 | FD9104 | |||

| Plate Diameter | Φ380 mm / 15 inches | Φ460mm / 18 inches | Φ610mm / 24 inches | Φ910mm / 36 inches | |||

| Max. Workpiece Diameter (without conditioning ring) | Φ180 mm | Φ220 mm | Φ270 mm | Φ420 mm | |||

| Conditioning Ring Diameter | Φ180 mm | Φ220 mm | Φ270 mm | Φ420 mm | |||

| Number of Station | 3 | 3 | 3 | 4 | |||

| Plate Rotate Speed | 0-140 rpm | 0-140 rpm | 0-120 rpm | 0-90 rpm | |||

| Facing & Grooving Speed (Not include in Polishing) | 0-120 mm/m | 0-120 mm/m | 0-120 mm/m | 0-120 mm/m | |||

| Total Weight | 450 kg | 780 kg | 1000 kg | 1600 kg | |||

| Total Floor Space | 670×940 mm | 1030×730 mm | 1920×840 mm | 2100×1300 mm | |||

| *NOTE: the optional kits based on the production requirements, making samples can confirm if they are necessary. | |||||||

Main uses:

Widely used in LED sapphire substrate, optical glass wafers, quartz wafers, silicon wafers, sheets, molds, light guide plates, light spinner joint valves, hydraulic tight, stainless steel, and other materials single-sided grinding, polishing.

grinding disc flatness can reach ±0.002mm; The flatness of the workpiece with a diameter of 50mm can reach 1/4 wavelength. The flatness of the workpiece after processing can reach ±0.0005mm.

the use of imported bearings, motors, to ensure the stability and life of the equipment, to ensure the precision requirements of the workpiece.

High precision grinding machine features:

1, frequency conversion control, soft start, soft stop, small impact, reduce workpiece damage.

2, using the timing function to control the time, processing products can be set in advance on the panel time and speed, working time jump to the set time, the machine automatically stops working, can better control the size of the product.

3, grinding machine workpiece pressure using weight weight pressure, polishing workpiece surface brightness, no scratch, no scratch, no grain, no pitting, no edge, high flatness characteristics. After polishing the workpiece surface roughness can reach Ra0.002;

4, the use of interval automatic spray device, can freely set the spray interval time, the grinding liquid can be evenly sprayed on the grinding disc, to achieve the stability of the workpiece. Reduce the grinding time, save the cost of consumables, but also meet the requirements of the environment.

SAMPLE DEMONSTRATION (SINGLE PLATE)

About the Company Ponda is a high-tech enterprise specializing in all kinds of high precision grinding equipment, polishing equipment and itssupporting products and consumable materials

We have a production workshop and testing equipment, assembly workers and mechanical design engineers45 people Patent

Delivery & Packing

Packing Details : Packing, 1 pcs/Wooden box.

FAQs

Q1: Which machine is most applicable for my product?

A: It usually depends on 5 requirements and parameters of your product: flatness, roughness, thickness, dimension, productivity:

1. If better flatness and roughness were required, you might need both lapping and polishing machine.

2. If to thin the product in a big margin, such as 500μm, you might need a thinner machine for extra.

3. If the productivity were excessive, you might need larger machine or to expand production line.

Additionally, we can confirm the production line as we make samples for you.

Q2: Does Ponda charge for making samples?

A: No, it's free to make samples.

Q3: Is Ponda trader or manufacturer?

A: We are manufacturer, certified National High-Tech Enterprise.

Q4: How long does it take machine to deliver?

A: Approximately 15 days to deliver. If the machine are out of stock, we need 15 days more to manufacture.

Q5: Does Ponda provide oversea setup and after-sale service?

A: Yes, we provide oversea service and online tutorial.

Q6: How many type of machine does Ponda manufacture?

A: We have 21 major series of machines, 5 different types run in different principles, more than 15 types of plates, 100 types of slurries.

>> Heavy Duty High Rigidity Metal Flat Bed CNC Lathe machine (BL-CKL series)

>> 18 HP Walking Tractor Greenhouses Rototillers Are Used on Farms

>> New Design LED Emergency Vehicle Warning Light with Scene Light

>> Fast Butt Welding Machine in China

>> Car Push Type E46 E90 Universal Plastic Retainer Rivet Fastener Clip

>> Stainless Steel 54qt Large Metal Cooler Ice Box Portable Outdoor Beverage Cooler Box for Picnic

>> Energy Bar Date Bar Fruit Bar Extruder Protein Bar Making Machine

>> pp/pe/ SMS Blue Standard Sterile Disposable Surgical Gown For Medical

>> Dimmer 0-10V Control IP65 UFO LED Grow Light

>> SE-1200V Energy-saving Efficiency Precision Eco-friendly Intelligence All Electric Injection Molding Machine

>> Shampoo Mixing Tank Laundry Liquid Mixing Tank High Viscosity Resin Disperser Liquid Mixer

>> Hot Sale High Capacity Maize Sheller 5ty Corn Thresher Machine for Sale

>> Unbreakable Personalized Candy Color Office/School Silicone Desk Pen Boxes

>> Pure White High Density PVC Foam Board Premium Quality Board

>> New Luxury Brand Custom Logo Genuine Leather Skeleton Automatic Watch Men Wrist Mechanical Watches

>> Factory HP Ink Cartridge HP 305 HP305 XL for HP Deskjet 2700 4100 Envy 6020 6030 6420 6430

>> High Purity 3303/2202/1101 Silicon Metal Low Price From China Factory

>> Acoustic panel boutique hardwood slab new house hotel bedroom design commercial solid core wood veneer cheap white interior door

>> Electric vehicle battery cable manufacturer direct sales

>> Eco-Friendly Recycled PP Non-Woven Fabric Shopping Tote Bags Foldable Handled Bags

>> A Grade Wholesale Top Wooden Clothes Hanger for Man Garment Furniture Hanger with Bar

>> Dtf Ink 1000ml 6pk Premium Water Based Digital Inkjet Ink Refill for Direct to Film Printer Replacement for EPS Series Printhead

>> High thermal insulation of UPVC material Sliding door separating plastic-steel slide Barn Doors

>> Tire Recycling System/Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder Tire Recycling Machine Recycling Line Plant

>> High Quality Chaochai Parts Magnetism Switch

>> VietNam BOPP Laminated Bags with Perforations

>> 2 Yrs Warranty UTHQA4 A3 A4 A5 Paper Cutting Machine and Packing Machine

>> Paper Roll with OEM Design Artwork Printing for Kids Drawing

>> Natural black obsidian green white jade roller gua sha set face massage jade roller

>> Hydrocolloid Microdart Pimple Patches Acne Spot Patches 1 Dots Microneedles Patch