Different Capacity Machine Making Gypsum Sheet Gypsum Sheets Machine

| US$300,000.00-500,000.00 | 1 set (MOQ) |

Basic Info.

Screw Design

Double-Screw

Certification

CE, ISO

Condition

New

Customized

Customized

Transport Package

Seafeight Package

Specification

according capacity

Trademark

yurui

Origin

Shandong

HS Code

8474809010

Production Capacity

200 Sets/Year

Product Description

| Output | 2million -30million sqm/year (based on thickness 9.5mm) |

| Fuel | coal; natural gas; diesel; heavy oil, etc |

| Technology | hot ai; heat transfer oil/thermal oil |

| Width | 1200mm,1220mm |

| Thickness | 6mm to 22mm |

| Length | 1500mm-300mm |

| Raw material | Natural gypusm powder ,phosphorus gypsum powder,Desulfurized gypsum powde |

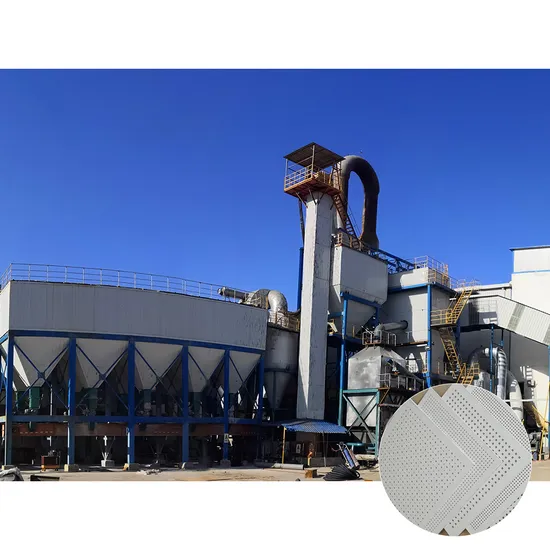

Factory view

Raw material request

| Raw materials | Item | Specification |

Calcined gypsum powder | Fineness | 0.2mm,<10% 0.2mm,Remnant<10% |

Initial set time | 3.5-5.5 3.5-5.5 minutes | |

Final set time | 7.5-10.5 7.5-10.5 minutes | |

Crystal water | 4.5%-5% | |

Half-water gypsum powder | >65% | |

| (2) Bending strength (2 hours) | 1.8 Mpa | |

Paper | Weight | 190-220g/ |

Thickness | 0.36-0.4mm | |

Air permeability | 0.85-1.6μm/pas | |

| (Cobb) Water absorption( Cobb ) | 15-30g/ | |

Tensile strength | 12.5 KN/m,3.5 KN/m Portrait 12.5 KN/m, transverse 3.5 KN/m | |

Transverse expansion and contraction | <2% | |

Moisture | 10%±2 | |

Denaturized starch | Content of the starch | >70% |

| Moisture | 11%-13% | |

| PH | 6.5-7.5 | |

| Protein | <0.3% | |

| 20ºC-40ºC Solubility in 20ºC-40ºC water | 73%-78% | |

Foaming agent | Condensate | >30% |

Ligarine | <3% | |

Inorganic salts | >2.5% | |

| PH | 7-9 | |

| water Water | PH | 6.5-7.5 |

Machinery introduce Dosing System

Application :used to dose and mix suitable of raw material to get the gypsum powder slurry.

Feature :

1.About raw material feeding system , we can equip for you wet raw material feeding and dry raw material feeding system to meet your demind .

2.About the mixer : we used the dawel pin type ,which is similar to German technology

Paper supply system

Application :Supply paper to the gypsum board

Composition:The paper roll lifting machine, uncoiling device, pneumatic paper receiving machine, paper storing machine, paper pulling machine, paper guiding machine, scoring machine and automatic correction machine. Forming and solidification system

Application :to form the semi-gypsum board from gypsum powder slurry , we have special design on the forming belt which can guarantee the board is very straight .

Automatic cutting system

Application: automatic cut the solidified gypsum board to setted size ,Dual servo cutting machine , more accurate ,and reduce board waste.

Transit System

Application:used to horizontally transport the cutted board to the distributor, other unqualified board will be send out of the production line

Distribution System

Application :used to transport wet gypsum board to each layer of the drying machine with the control of PLC Drying system

Application :Used to dry the forming board .For big capacity ,we adopt the hot air circulation, drying room temperature is uniform, the board has high strength and is not fragile. This part we can design according to client requirement

Labor requirements

| System | Workers needed |

| Dosing.mixing material system | 2/ 1workers/shift |

| PLC control | 1/ 1workers/shift |

| Forming system | 1/ 1 worker/shift |

| #2 #1Horizontal conveying system | 1/ 1 worker/shift |

| Drying system | 1/ 1 worker/shift |

| Boiler heating system | 2/ 1 worker/shift |

| Substitute person | 1 1 worker |

| \ Monitor\ forklift | 2/ 2 worker/shift |

| Package | 3-5 3-5 worker |

| Total | 13-15/ 13-15workers/shift |

If you have any questiones, Mary here service for you.

>> Toilet Paper and Kitchen Towel Making Machine Production Line

>> Motorcycle Parts Accessories Engine Parts Body Parts for Honda Xr150L

>> Top Selling Wireless Power Bank Portable Charger Cheap Mini Built in 4 Cables 10000mAh Powerbank with Wireless Charging

>> 2PCS Door Guard Protection Scratch Car Door Anti-Collision Strip

>> SHENGKE Square Watch Woman Stainless Steel Mesh Band Quartz Watches For Ladies Silver Golden Black Colors Fashion Lady K0119L

>> Air Conditioning Blanket Square Tmc2100 Stepper Moto Siheng NEMA 34 Lamb Blanket. 4nm 5.8A 4wires Cloth Industrial

>> Custom Precision CNC Turning Machining Parts Stainless Steel Turning Cutting Milling with Service

>> Factory Modern Hurricane Impact Casement Hollow Double Glass Sliding Aluminum Windows and Doors Building Glass Windows China

>> Hot Series Coil OEM Price Magnetic 600A Single Phase Cj12 Russia Motor Contactor

>> Garbage Collector Boat Water Hyacinth Harvester Machine Floating Trash Skimmer

>> Tianyu Aluminum Stand Exhibition Booth

>> Stainless Steel hexagonal perforated mesh for various decoration

>> SS304 SS316 DIN912 Socket Cylinder Allen Hex Socket Head Cap Knurled Screw

>> 300L Cosmetic Cream Mixing Machine Vacuum with Quality Supplier 100L Homogenizer Mixer with Priced to Sell CE Certificate

>> Ce Approved Pur Water Filters Replacement Pur Water Filter

>> Wholesale Popular Organic Fruit Tea for Health Care and Wellness

>> OEM True Capacity Fast Speed Memory Card Cartao De Memoria 16GB 32GB TF Cards Kart 128GB 64GB Custom SD 32GB Flash Memory Card

>> Square perforated mesh car audio horn metal grille

>> 84PCS. 917-1.000" M7 High Precision Smooth Pin Plug Gauge

>> Atlas 1614905400 Oil Gas Separator Replacement for Screw Compressors Filter

>> Waterjet Machine Spare Parts Water Switch Adapter Hr11085

>> MAICTOP high quality tail lamp for landcruiser 2008-2012 model uzj200 lights

>> Direct Reading Fresh Concrete Air Meter for Construction Test

>> Advancced Continous HDPE PP Extrusion Blow Moulding Machine - Ebm

>> Wholesale bulk sunflower seeds raw sunflower kernels Export sunflower seeds

>> Heat-Transfer Lanyard with Custom Logo Printing Logo

>> CNC Flange Drilling and Milling Machine

>> Orient Inflatables Event Interactive Mechanical Inflatable Surfing Game

>> V 20 Type High Efficient Small V Shape Blender Machine

>> Motorcycle Saddle Bags Black Brown Leather Motorbike Side Tool Tail Bag PU Luggage Universal