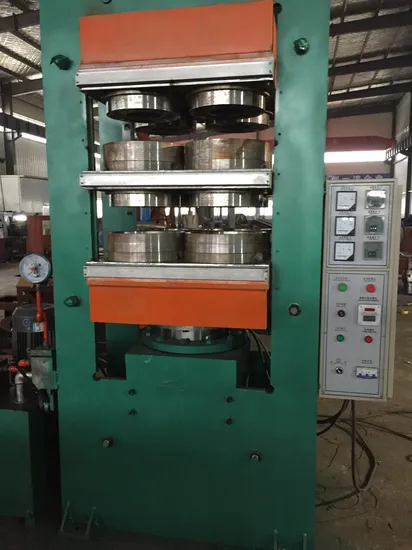

Solid Rubber Wheel Making/Wheelbarrow Solid Tire Making/ Rubber Powder Wheel Making Machine/Rubber Press

Basic Info.

Model NO.

XLB800*800*2

Certification

ISO

Condition

New

Customized

Customized

Automatic Grade

Automatic

Structure

Horizontal

Place of Origin

Shandong, China

Type

Vulcanizer

Video Outgoing-Inspection

Provided

Machinery Test Report

Provided

Core Components

PLC, Motor, Gear

Key Selling Points

Competitive Price

Weight (Kg)

2600 Kg

Applicable Industries

Rubber

Power (Kw)

3 Kw

Total Pressure(Mn)

1.60

Dayloigh(mm)

125

Working Layer

2

Piston Stroke(mm)

500

Heating Mode

Electric Heating

Mode of Production

Support Customization

Transport Package

Customization

Specification

1730*930*2460mm

Trademark

wanflon

Origin

China

HS Code

8477590000

Production Capacity

15 Set/Sets Per Month

Packaging & Delivery

Package Size

230.00cm * 120.00cm * 150.00cm

Package Gross Weight

4000.000kg

Product Description

Specification| item | value |

| Place of Origin | China |

| Shandong | |

| Brand Name | wanflon |

| Type | Vulcanizer |

| Condition | New |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | Hot Product 2024 |

| Warranty of core components | 2 Years |

| Core Components | PLC, Motor, Gear |

| Tire Machine Type | Other Tire Machine |

| Voltage | Required |

| Dimension(L*W*H) | 1730*930*2460mm |

| Certification | ISO9001:2008/CE/SGS |

| Year | Customization |

| Warranty | 2 Years |

| Video technical support | |

| Key Selling Points | Competitive Price |

| Power (kW) | 3kW |

| Weight (KG) | 2600KG |

| After Warranty Service | Video technical support, Spare parts |

| Applicable Industries | Rubber |

| Local Service Location | None |

| Showroom Location | None |

| Total Pressure(MN) | 1.60 |

| Dayloigh(mm) | 125 |

| Working Layer | 2 |

| Piston Stroke(mm) | 500 |

| Main Motor Power(KW) | 3 |

| Control Type | PLC |

| Warranty | 2 years |

| After-sales Service Provided | Video Technical Support |

| Heating Mode | Electric Heating |

| Mode Of Production | Support Customization |

1. Simple and convenient structure, flexible operation, commodious space. The cylinder and plunger are made up of high quality materials. 2. Being a column structure and downward pressing type, the heating plate opens by the self-weight of the heating plate, platform and plunger. The rising of the plunger makes the heating plate close while the hydraulic oil provides the pressure. 3. Electrical control system:Complete the perfect control system (including wire and cable and safety protection devices, etc.),Use automatic time relay,can achieve Automatic close mold,exhaust,stuffy,Vulcanization time, supplement pressure,open mold etc working process, also the automatic control and hand control can be switched easily. 4. Up and down platforms:Adopts Q235 steel plates. In order to guarantee the make precision, it is applied with automatic cutting baiting, mechanical slicer producing welded groove, carbon dioxide gas shielded welding. 5. Hydro-cylinder:Adopts ZG270-500 and piston stroke adpots hard cold chilled alloy cast iron, And sealing structure applies the combined structure with double sealing ring and one dustproof ring to guarantee longer service. 6. Customers can choose according to their needs. 7. New design concept, strong technical force and advanced manufacturing processes of the press ensures that each vulcanizing press can be manufactured to meet customer's individual requests.

>> 2025 New Crop Dried Red Chilli From Kailu, Inner Mongolia, China

>> 2K HD Video Glasses Camera Portable Outdoor Sport Driving Recorder

>> Mg-B600 Disposable Paper Bowl Food Container Forming Making Machine Price for Hot Soup Salad Bowl Producing Machinery

>> Oil and Vinegar Bottle Set 5oz,2 Pack, Comes with Stainless Steel Rack, Removable Cork, Funnel

>> High quality aftermarket full LED laser headlamp headlight for BMW 7 seriesG12 head lamp head light 2016-2019

>> Mini Easy Version Grandma2 Command Wing Onpc Lighting Console Ma Portable

>> Xiaomi Redmi airdots Pro headset wireless headset gaming headset and microphone

>> Z3040*13 Multi Form Processing Vertical Drilling Machine with CE Marked

>> PP/PE Waste Plastic Recycling Granular Machine Manufacture

>> Wc67K 160t/3200 Torsion Axis Servo CNC Hydraulic Press Brake Machine

>> Ferro scanning rebar scanner search bar in concrete rebar detector ZBL-R630A

>> Wholesale 2 in 1 Floor Brush Adjustable Cleaning Brush Bathroom Floor Crevice Cleaning Brush with squeegee

>> File Cabinet Office Furniture Cabinet Storage Cabinet Support Customization

>> Customized Automatic Plane Slotting Machine for Granite Tile Blind Slab Paving Stone Grooving Cutting

>> Decoration Curtain Mesh Wall Aluminum Perforated Metal Mesh Decorative Woven Metal Perforated Plain Weave

>> CNC Cylindrical Grinder Machine Mak1320h Make1320h

>> Agricultural Machinery Tractor Cultivator with ISO9001

>> Fiber Laser Welding Machine Automatic and Handheld Optional Hot Sale

>> Vertical Machining Center Fanuc Control CNC Milling Machine Szgh-46y Full Guard 4 Axis Max Ordinary Duty Travel Marketing Kingdom

>> 500kw Oilfield Associated Gas Generator Set

>> Wholesale Different Size Disposable Isolation Gown Non-Woven Blue PP with Knit Cuff

>> Ranbem Self-Cleaning Automatic Hot Liquid Soy Milk Soup Maker Machine Mini Soup Maker Electric Blender

>> Hot Selling Angel Ornaments Table Decorations Resin Crafts Sculptures

>> Super Bright Headlight (halogen) FOR 2019 ALTIMA

>> 6000lb 12V Winch with Steel Rope and Wireless Remote

>> Romantic Battery Operated LED Flameless Pillar Candles

>> Commercial Trampoline Park Solutions for Exciting Entertainment Venues

>> Wholesale Best Products 2022 Customizable Quartz Watch OEM ODM Elegant Sport Woman Bracelet Watches Set Wristwatches For Woman

>> Wood Simple Hot Selling Nordic Wooden Table Set Dining Table with Chair

>> CPC in-Line Hose Barb with Shut off Straight Thru CPC Coupling Conntector