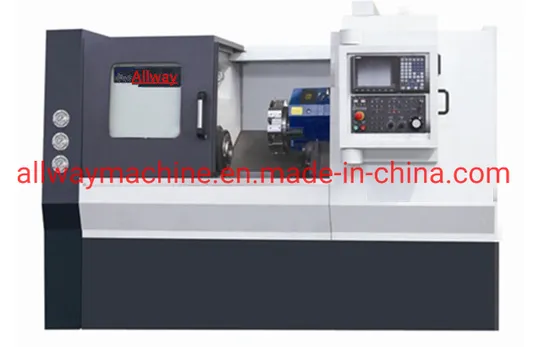

CNC Lathe Machine with Linear Guideway Slant Bed

Basic Info.

Model NO.

CLK500

Type

Horizontal Lathe

Processing Accessory

Chuck CNC Lathe

Guide Rail

Inclined Guide Rail

Tool Holder

Double-tool Holder CNC Lathe

Power Source

Electric

Controlling Mode

CNC

Automatic Grade

Automatic

Setting Mode

Floor-type

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

Slant Bed

High Precision

Transport Package

Plywwod

Specification

CLK520

Origin

China

HS Code

84581100

Production Capacity

1000PCS/Year

Product Description

CLK500 SLANT BED CNC LATHE MACHINE1. CLK500 SLANT BED CNC LATHE MACHINE SPECIFICATION

| max. swing over bed | mm | 500 |

| max. swing over cross slide | mm | 300 |

| max. processing length | mm | 500 |

| X/Z axis travel | mm | 220/500 |

| spindle nose | A2-6 | |

| spindle bore | mm | 66 |

| spindle drawing pipe diameter | mm | 50 |

| max. spindle speed | rpm | 3000 |

| chuck size | inch | 8 |

| spindle motor power | kw | 7.5 |

| X/Z position accuracy | mm | 0.016/0.02mm |

| X/Z repeatability | mm | 0.006/0.006mm |

| X/Z feed motor torque | N.m | 7.5/10 |

| X/Z feed motor power | kw | 1.3/1.88 |

| X/Z rapid feeding speed | m/min | 10 |

| tailstock travel | mm | 350 |

| tailstock sleeve diameter | mm | 90 |

| tailstock sleeve taper | MT5# | |

| tool post type | 8 station hydraulic turret | |

| cutting tool shape size | mm | 25*25 |

| guide type | Taiwan HIWIN linear guide way | |

| total power capacity | kva | 15 |

| machine dimension L*W*H | mm | 2450*1600*1700 |

| N.W. | kg | 4000 |

2.CLK500 SLANT BED CNC LATHE FEATURES

Taiwan high accuracy HIWIN linear

Taiwan famous brand ball screw

hydraulic magazine

hydraulic chuck

hydraulic tailstock

thur-hole type rotary cylinder

3. CLK500 SLANT BED CNC LATHE USAGE

This machine is applicable to automobile, motorcycle, electronics, aerospace, military, oil and other

industry. It could turn the conical surface, circular arc surface, end face of the rotary parts, could also

turn various metric and inch threads etc, with higher efficiency and higher precision in bulk.

4.CLK500 SLANT BED CNC LATHE STANDARD ACCESSORIES

GSK980TDC or Siemens 808D

Servo main motor 7.5kw

8 station hydraulic magazine

8" domestic thru-hole type hydraulic chuck

hydraulic tailstock

lubrication system

coolant system

lighten system

5.CLK500 SLANT BED CNC LATHE OPTIONAL ACCESSORIES

NC System: Mitsubishi E60, Fanuc Oi Mate-T

Main Motor: Servo11/15KW

Inverter15KW

Chuck: 8″Non-through hole hydraulic chuck

8″Non-through hole hydraulic chuck (Taiwan)

8″through hole hydraulic chuck(Taiwan)

10″Non-through hole hydraulic chuck (Taiwan)

10″through hole hydraulic chuck(Taiwan)

Chip conveyor

Steady Rest

Without hydraulic tailstock

>> Isuzu 2ton 3ton 4 Ton Mini Hook Lift Trucks 2 Ton Hook Lift Arm Roll off Garbage Truck

>> Anti-Yellow Agent for Pet Resin Yellow Elimination Remove Yellowing Recycled Pet Resin

>> connector Rapido De Fibra Optica Fast Connector 50mm Sc5009 APC connector Fiber Quick Connector

>> Professional Audio Maufactuer 6.5 Inch Car Speaker Midrange with Colorful Basket

>> Steel Flooring Anti-Static Raised Floor Steel Cement Floor for Building Material

>> 1000mm PP Double Layers Film Blown Machine

>> 170f Gasoline Engine Cultivator Four-Stroke Farm Machinery Single-Cylinder Agricultural Power Weeder Mini Tiller

>> 87326910 Engine Belt Tensioner for Case Tractor

>> High Quality of 60HP Kubota DC60 Small Combine Harveste

>> Condom Brust Tester

>> RFID Proximity Card Time Attendance Access Control Device with USB, TCP/IP

>> High Quality Industrial Working Boots Steel Toe Safety Shoes

>> S Size of Reclaimed Wooden Planter Pot with Black Metal Frame

>> Laser Intelligence Edge Banding Machine

>> Strict Quality Control Aluminum Open Cell Ceiling Metal Grill Ceiling

>> Eaton Vickers DG4V5 Series Solenoid Directional Valve for diesel Material Handling

>> Unlocked Huawei E8372h-320 LTE 4G USB WiFi Modem Dongle

>> 10PCS/Set White Mini Stretched Artist Canvas Blank Art Boards Art Board Acrylic Oil Paint Wood+Cotton Artwork Painting 10*10cm

>> Quality aluminium patio corner sliding glass doors price bangladesh

>> World Agricultural Machinery 4lz-4.0e Combine Harvester Price

>> High-Frequency ERW Welding Tube Mill Machinery for Diverse Pipe Making Shape Manufacturing

>> Factory Price Multi-Style Copper Aluminum Connecting Electrical Connectors Ring Terminals Wire Bimetallic Automotive Cable Bimetal Lugs

>> Wholesale High Efficiency Automatic Centrifugal Discharge Water/Oil Filter for Lubricating/Hydraulic/Turbine/Fuel/Diesel/Engine Industrial Oil

>> Hot Sale Welded Wire Mesh Layer Battery Farm for Sri Lanka Gamefowl Chicken Cage with Great Price

>> Advanced Food Processing Equipment for Baguette and Bread

>> Kerala wood panel door designs

>> 24LED Trailer Combination Light with Reflex Reflector

>> concrete strength test concrete rebound hammer for measuring concrete

>> Chaozhou Luxury Bathroom Ceramic Pedestal Basin Sink Two-Piece Hand Wash Basin

>> Indoor ceiling mesh and outdoor curtain wall aluminum wire mesh expanded metal mesh