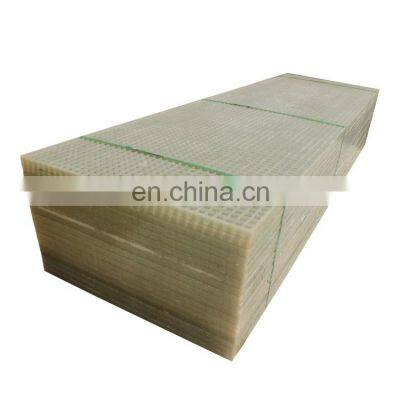

China factory price fiberglass grating FRP Composite Industrial Fibreglass grating floor

Product Description

Product DescriptionProduct DescriptionChina factory price fiberglass grating FRP Composite Industrial Fibreglass grating floorFiberglass reinforced plastic grating (also known as FRP grating, glass reinforced plastic grating or fiberglass grating) is a composite material manufactured by combining a matrix of resin and fiberglass. Fiberglass grating does not corrode like steel grating and is therefore used in corrosive environments to reduce maintenance costs.Lanyu is the leading supplier of molded fiberglass gratings. Our manufacturing process utilizes a proprietary manufacturing technique that allows us to introduce more glass rovings into the laminate.Essentially, molded FRP grating consists of two components–fiberglass rovings and resin. The glass provides the strength, and the resin provides the resistance to the environment (i.e., the corrosion resistance, the UV resistance, the impact resistance, etc.). The higher the glass-content, the stronger the grating. Material advantages:Strong bearing capacityStretch-proofHigh-temperature resistanceAnti-corrosionNon-flammableGood insulationNo rustNon-slipMildewproofAnti-shrinkageEasy to cutEnvironmental protectionSpecification Fiberglass Grating has many sizes for you to choose.ThicknessmmMesh SizemmPanel SizemmOpen Area%Unit Weightkg4040*401007*300764602538*381220*366069523838*381220*366069855050*501220*3660721003038*381000*04069753825*1521145*290060763025*251220*3660648450*503819*191007*4007729238*38Production steps:1. Stirring raw materialsResin, fiberglass fiber yarn, calcium powder filling, color paste, reagents, etc. are arranged in proportion, stirring for 20 minutes.2 . Draw yarnLay the alkali-free yarn layer by layer to improve the strength of the FRP grating.3 . Compression moldThe stirred raw materials are poured into the mold and compacted mechanically or manually.4 . Heat curingAfter the grating is heated for 20 minutes, the raw materials and yarn are fused together.5 . Cooling demoulding, mold liftingAfter the above process is completed, cooling for 10 minutes demolding, mold lifting, semi-finished grating finished.6 . Grinding, painting and washingThe FRP grating is polished and washed with a layer of varnish or water.PackingFRP grating application:ConstructionGuardrails, stairs, ladders, wall gratings, platforms, etc.Drainage treatmentDrainage ditch, drain grating, platform, structure, etc.Civil EngineeringFloors, sidewalks, bridges, tree protection, car washes, parking lots, Protect grating, etc.Chemical IndustryWork platform etc.Food processing and aquacultureThe platform, engineering guardrail, etc.Ocean industryPlatforms, fencing, sidewalks, etc.Details ImagesMolded FRP grating is composed of alternating directional layers of continuous glass fiber for strength, with resin to consolidate the fibers and provide the shape and corrosion-resistance. Molded grating has very high impact tolerance, as well as the highest chemical resistance of any fiberglass grating. It can be made slip-resistant by adding grit to the surface.FRP grating sheet Features---Strong, Lightweight and Corrosion-ResistantMolded FRP Grating has the strength of steel, but it won’t corrode like steel can.---Safer Walking Surface for Trench Covers and Fiberglass WalkwaysA coarse, gritted epoxy coating enhances traction.---Support and StabilityMolded Fiberglass Grating Panels are equally strong in both directions---Easy FabricationFRP Flooring Panels are lightweight, easy to transport, and can be cut and fabricated using standard hand tools.---Extended LifeThe coated resin surface increases resistance to chemical corrosion and continuous UV exposure.LIGHTER THAN STEEL:High Strength Molded Fiberglass Gratings are one third to one half the weight of steel gratings while offering the same stiffness.IMPACT RESISTANCE:Our gratings possess better impact resistance than steel gratings.FIRE RETARDANT:High Strength Molded Gratings are designed to achieve a minimum of a Class 1 Flame Spread RatingNON-SKID RESISTANCE:Molded Gratings possess the most positive anti-slip characteristics on the market. The non-skid characteristic is provided by a concave meniscus contour on the top of the bearing bars or by a secondary application of silica grit.LOW MAINTENANCE:Install it and forget about it. It will not rust!!!OTHER POSITIVE FEATURES INCLUDE:Electrically and thermally non-conductiveEasy to cut and installUV resistantFiberglass grating accessories: M-type,S-type,C-type.Product packagingFiberglass Grating is usually packed by the pallet.To protect the FRP grating well, we also do Corner guard with film wrap.FAQQ: How can you guarantee your product quality? A: 100% of our products will be tested before delivery. To control quality, we are using high quality material from high quality supplier. Q: Are you a trading company or a manufacturing factory? A:We are a manufacturing factory with export qualifications. Our factory is one of the Best FRP products manufacturer in China since 2010.We have FRP products of high quality and various kinds. Q: I am interested in your products, could I get sample for free? A: We could supply a few pieces of FREE samples if we have some in stock. All you need to do is kindly offering your shipping account. Q: Can you do the design for us? A: Yes. With experienced teams in fiberglass product design and manufacturing, we can provide customizedshape,dimension, colors service.Our factory can produce hot sale fire resistant reinforce frp grating sheet according to customer requirement, please contact us freely for a quotation.FRP grating solutions has expanded progressively and now includes extensive grating offerings with a wide range of ancillary components and fixings. For the complete range and technical details of our FRP grating offerings, please refer to me as following:

>> Hydraulic Wood Grapple, Log Grapple for Excavator

>> Dynapac Type Coulings Concrete Vibrator

>> Rotary Blow Molding Machine for 330ml Bottle

>> Leekon Wholesale/Custom High Quality Aluminium Professional Spin Bike Cardio Machine Commercial Workout Equipment

>> Factory Price 6000 Games Console Wireless Charger Power Bank Movie Player MP4 Ebook All in One

>> Truck Mixer Selling with Best Price From China Manufacturer

>> Factory Price Customizable Ck5280 Flexible Efficient Milling Turning Lathe Machine Vertically

>> 4 Rows Maize Straw Sweet Corn Silage Forage Harvester Price in Sri Lanka

>> PP836A

>> Wholesale price custom oem portable mini military medical first aid kit

>> Long Service Life New Style High-Speed Injection Molding Machine for Thin Wall Product Hxh520

>> Wall to Wall Wool Commercial Axminster Floor Hotel Carpet with Modern Chinese Custom Pattern Machine Made Woolen Polyester Flooring Carpet-Rug-Mat Factory Price

>> Automatic Panel Bending Centre Lanhao CNC Machine

>> Automatic Chemical Degumming Line for Hemp or Flax Fiber

>> Modern Design Easy Click PVC Vinyl Laminate Flooring Free Sample

>> Professional Power 65cc Garden Machine Farm Rotary Gasoline Cultivator and Power Weeder

>> Composite slab composite stone Synthetic marble Synthetic quartz stone

>> 10PCS Stainless Steel Needles for Animals Injection Syringe Vaccination Vet Farm Tools Poultry Livestock Veterinary Use Farming

>> Free Sample Eco-Safe Pet Erasable Magnetic Whiteboard for Advertising & Exhibition

>> OEM BR3Z6K254B Timing Chain Tensioner for Ford F150 F-150 5.0L TN1605

>> Household Voltage Regulators: Steady Power for Your Home

>> Revlon Make-up Cardboard Display Stands, Cosmetic Display for Beauty Products

>> Low Price 4 Quick Change Tool Post Horizontal Manual Lathe Machine

>> Industrial High-Efficiency Pin-Type Bead Mill for Ultra-Fine Grinding of Paints, Pigments, Inks & Carbon Black 150L, 250kw, Nano Grinding

>> 30 minutes treatment strong improvement in blood flow, oxygenation, metabolism of the cells, optimizing nervous system

>> China Professional Maufacturer Rubber Conveyor Belts Making Machine

>> V-Show Indoor LED PAR Light Disco Stage Lighting

>> Injectable Cross Linked Hyaluronic Acid Sodium Hyaluronate Dermal Filler for Face Lip Breast Buttocks Penis Enlargement Facial Wrinkle Ha Injection Hyaluron Pen

>> High quality 26 inch light bike adult mountain bike for sale

>> 3HAC17484-8108 ABB module supply