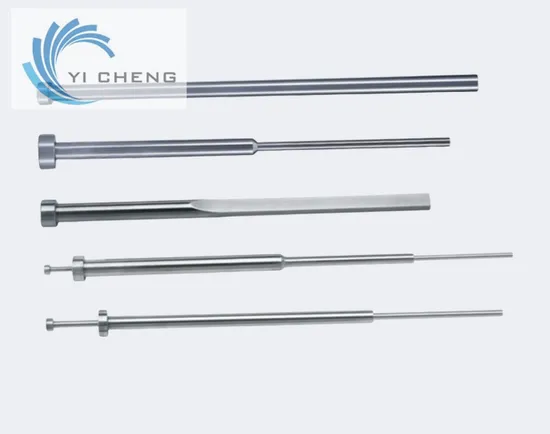

Precision Ejector Sleeves and Core Pins for Mold Injection Systems Plastic Injection Mold

| US$1.00-25.00 | 10 Pieces (MOQ) |

Basic Info.

Model NO.

00010

Material

Skh51 , DC53, SKD11, Asp23

Processing Method

Customized

Technics

Customized

Process Combination

N/a

Manufacturing Technology

High Frequency Quenching,

Driving Motor Type

Turning Machine, Milling Machine,

Mold Cavity Technology

N/a

Milling Speed

Normal Speed

Parts Detection Method

Micrometer, Caliper,

After-sales Service

Guarantee Each PCS Is High Quality

Transport Package

Bubble Bag, Plastic Box, Cartons, or Wooden

Specification

Customized

Trademark

Customized

Origin

Guangdong China

HS Code

8401409090

Production Capacity

100000/Year

Product Description

About us :

Reliable mold punch, various ejector pin, mould accessories, tungsten carbide products, ejector pin, step pin etc manufacturer! !

full line of standard and custom punch products, mould accessories and die parts to high quality standards giving you the reliability and dependable performance you expect. Punches have always been our main products through the years, we have developed expertise in manufacturing a wide range of them. Designed and manufactured for sound performance and long service life. Our products are manufactured to exacting tolerances to assure interchangeability. Each component is made of quality material.

| Product name | Punch |

| Surface treatment method | Black-plated titanium, yellow-plated titanium, chrome-plated, nickel-plated |

| Heat treatment method | High frequency quenching, vacuum heat treatment, quenching and tempering treatment |

| Size | Standard and customers design |

| Tolerance | Standard or + - 0.002mm |

| Maine equipment | Machining center, CNC, Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Wire cutting machine etc. |

| Application | Light Duty/Heavy Duty, Machine Parts, Mold Parts, Spare Parts, Car Parts, Auto Parts |

>> Long Span Corrugated Roof Solar Panels Insulated Roof Synthetic Resin Tile

>> Growatt China Best Inversor PV Pure Wave Energy SPF 6000es Plus 6kw 6kVA off-Grid DC AC Price Power off Grid Hybrid Solar Inverter MPPT for Home Sustainable

>> Sale for Hydraulic Scarp Metal Baler Quality Guarantee From China Factory

>> Factory Custom Embroidery Print wholesale crew neck sweat shirts cotton plain oversized custom crewn

>> RS232 Control 1080P 60fps 10X Auto Focus HDMI USB3.0 RJ45 Video Conferencing Camera

>> Scrap Car Tire Shredder Small Rubber Crusher Tyre Shredding Machine for Sale

>> Full Pneumatic Man Lift for Sale

>> Cnc machine tools for lathe processing parts process stainless steel precision casting cnc machining stainless steel parts

>> Commercial Industrial Bakery Electric and Gas Deck Pizza Bread Baking Oven

>> Custom Good Price Large Fruit Weaved Straw Storage Round Seagrass Baskets

>> MAICTOP car accessories led headlight front bumper for fj cruiser 2007-2015 headlight car grills

>> Amazing Corn Puffed Food Extruder Machine for Food Industry

>> Factory Custom Women Seamless Nursing Bra Smoothing Seamless Stretch Wireless Lightly Lined Comfort Wire Free Basic Bras

>> Christmas Plush Angel Girls Doll Xmas Tree Hanging Pendants Christmas 2022 Decor For Home 2023 Kids Navidada Gifts Favor

>> Taijia Fixed ultrasonic flowmeter ultrasonic flow meter with rs485 dalian

>> 369-HI-0-0-0-0

>> Automatic urban garbage sorting plant municipal solid waste sorting lines mobile trommel screen

>> Easy to Wash Blender Detergent Mixer Stainless Steel Dishwasher Cleanser Machines Manufacture Liquid Soap Mixing Tank High Speed Shear Making Mixer

>> Golden Cup Good Quality Cola Paper Cup Machine

>> Strong Cutting for Both Vertical and Horizontal Use

>> Hot Selling Cross Linked Hyaluronic Acid Dermal Filler

>> OEM Timing Chain Kit for MERCEDES-BENZ TK1220-8 for Engine No.M271 With oe no.0009932176 0009932076

>> Customized Cheap Shoulder Bag Sling Bag Non-Woven Messenger Bag

>> Elastic Bandage Wrap with Yellow Line – Premium Stretchable Bandage for Medical & Sports Use

>> High Productivity 30 Ton Hydraulic Press Brake Machine Mechanical Wd67K Press Brake Carbon Steel Core Bearing Gear Engine

>> DAIWA Big Trolling Fishing Reels Feeder Metal Fishing Reel Carp Surf Casting Reel

>> Black Fungus Multi-head Weigher Automatic Packaging Grains Ziplock Pouch Granular Premade Bag Packing Machine

>> 170 Gasoline Driven 1m Working Width Paddy Rice Reaper Binder

>> Professional Running Waist Bag for Women Invisible Running Phone Bag Marathon Outdoor Multi Functional Sports Belt for Men

>> OEM CNC Machining Customization Services Stainless Steel Aluminum Threaded Parts CNC Machining Service