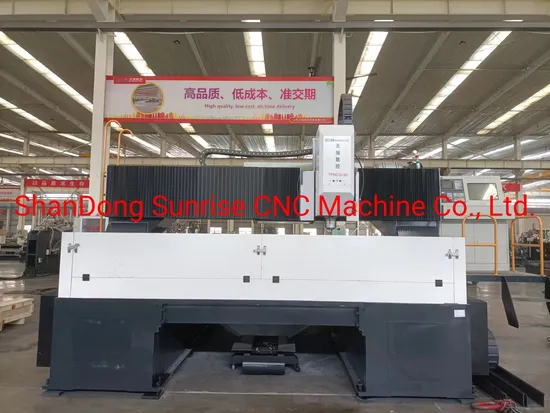

TPHD3230-1 CNC One- Spindle Gantry Movable High-Speed Drilling Machine

| Negotiable | 1 Piece (MOQ) |

Basic Info.

Model NO.

TPHD3230-1

Structure

Vertical Drilling Machine

Layout

Horizontal

Controlling Mode

CNC

Number of Shaft

3

Hole Diameter

50-100mm

Automatic Grade

Automatic

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Transport Package

Plywood Case

Specification

4.9× 3.9× 3.2m

Trademark

SUNRISE

Origin

China

HS Code

8459210000

Production Capacity

200 Sets/Year

Product Description

Applicable Industry: This machine is mainly used for drilling and milling of steel plate in the steel structure industry such as building, bridge, iron tower, etc., and can also be used for drilling and light milling of tube plate, baffle plate and circular flange in boiler and petrochemical industry. It is used for drilling through hole, blind hole, ladder hole, chamfering and milling. Maximum processing range is 2000 x 1600mm.

Specification:

| Model | TPHD3230-1 | |

| Max. size | L X W | 3200X3000mm |

| Max thickness | 250mm | |

| Work table | Width of T slot | 28 mm |

| Vertical slide type drill head | Quantity | 1 |

| Main spindle taper hole | BT50 | |

| Max drill diameter(common carbon steel) | φ40mm(carbide drill) | |

| φ50mm(high speed twist drill) | ||

| Main spindle speed | 30-3000r/min | |

| Motor power of spindle | 22kW | |

| (X axis) Gantry longitudinal move | Max. stroke | 3200mm |

| Moving speed of X axis | 0-8m/min | |

| (Y axis) Power head transversal move | Max stroke | 3000mm |

| Moving speed of Y axis | 0-8m/min | |

| (Z axis) Vertical slider feeding | Stroke of Z axis | 500mm |

| Feeding speed of Z axis | 0-5m/min | |

| Positioning accuracy | X/Y axis | ≤0.08mm/ Full length |

| Repositioning accuracy | X/Y axis | ≤0.04mm |

| Hydraulic system | Hydraulic pump pressure/flow rate | 6.5MPa /25L/min |

| Pneumatic system | Compressed air pressure | ≥0.4MPa |

| Chip cleaning and cooling | Chip cleaner type | Plate chain type |

| Chip cleaner no. | 1 | |

| Chip cleaning speed | 1m/min | |

| Automatic lubricating system | Lubrication pressure | 2MPa |

| Lubrication point oil injecting amount | 0.1mL | |

| Lubrication period | 6-10min | |

| Electric system | CNC system | FAGOR8055 or SIEMENS |

| CNC axis NO. | 4 | |

Packing & Delivery

Packing Details : Packing, this model need 2*40HQ;

Delivery Details : 30-50 days after get the first payment.

1. Special logistics packaging

2. Suitable carton size

3. Fasten

4. Professional placement

5. Professional shock

6. Complete package

Our Workshop:

The company covers an area of more than 46000 square meters. , with built production workshop 33000 square meters.

Aftersale Service:

India and some other countries could provide to door service. For those we cannot go to factory at site, we will provide full details installation guidance and give remote support by internet (Wechat, whatsapp, zoom, telephone, email, teamviewer).

Our Certifications:

SUNRISE is focus on quality and has already passed ISO9001:2015 certification, CE certificate, also with more than ten own intellectual property rights and patent technology.

Quality Make Brand, Honesty Win Market!

Innovation Promote Development, Harmony Converage Talents.

Thanks For All Customers Believe And Choose Sunrise CNC.

>> Cosmetic Packaging Round Glass Bottle Aluminium Caps Dropper for Rose Essential Oil Bottle

>> Luxury Europe front safety door design cast aluminum doors entrance

>> Modern Luxury Home Furniture Lounge Living Room Relaxing Genuine Leather Leisure Chair

>> Economic CNC Gear 4-Axis Hobbing Machine Max Dia 280mm Workpiece, 1-3 Module Range

>> Xingpai Brand Multi-Layer Three Layer Co-Extrusion LDPE HDPE PE Film Blowing Machine Plastic Extruder Biodegradable Plastic Blown Film Extrusion Machine

>> AAA Quality 100% Garanty Top Selling Mobile/Cell Phone LCD for Samsung Note 20/Note 10/Note 9/Note 8/S22/S22 Plus/S22 Ultra/S21/S10/S10 Plus/S9/S9 Plus/S8 G950

>> All Tag Security 58kHz EAS Am Tag

>> Hot Sale Multi Function Korean Premade Bag Food Vacuum Sealing Meat Product Making Packing Machinery Meat Packaging Machine

>> Chicken House Light Trap Light Filter for Exhaust Fan

>> Soft Summer Home Cotton Linen Slipper Unisex Comfotable Slipper Sandal

>> Aluminum Hinged Door

>> PE Plastic Bin Liner Shopping Bag Vest T-Shirt Bag Film Blowing Machine

>> Facade cladding perforated metal sheet Crush-resistance excellent product

>> Sj-a Model High Speed Biodegradable PLA Pbat Sigle Layer Extruder Blown Extrusion Line Plastic Film Blowing Machine Price for LLDPE LDPE and HDPE

>> Louver Folding Door Double Glazingfolding Door And Windows Sound Prooffolding Door

>> Fish Bone Porcelain Ceramic Tiles Wall Tiles Designs Modern Floor Tile

>> Domestic Waste Treatment (Xinzhou Brand)

>> Smart Electric Kettle Commercial Electric Water Glass Kettle with Thermostat Function

>> [SHENGHE] EPC Available Completed NMP Recycling System (NMP Recovery+Distillation+Tank Farm)

>> Sea Bass Minnow DAIWA SALTIGA FK JIG TG Fishing Lures Saltwater Artificial Fishing Bait Pike Bait

>> Cheap Price 1500W Laser Welding Machine for Metal

>> New Chinese Waterproof Outdoor Lawn Lamp Courtyard Passage Lamp Villa Garden Landscape Lantern

>> Satisfaction Guarantee Skin-Friendly Baseball Cap Quick Drying Canvas Hat for Stadium

>> KB045CP0 Slim Ring Types Thin Bearing Radial Contact Thin Section Bearings KB Series Thin Bearings KB045CP0

>> New LEXUS OEM FACTORY CHROME GRILL SURROUND 2013- CT200H 53121-76010

>> 500W/750W Bafun Bafang Motor Fat Tire Mountain Wholesale Electric Bicycle

>> Hot Sale Xuchang Factory Wholesale Raw Vietnamese Virgin Human Hair Short 4# Colored 13X4 Bob Transparent HD Lace Front Hand Made Wig for Black Women

>> 10241841 Timing Chain for ROEWE RX5 2.0T Engine 20L4E 18L4E TC2030

>> Customized 8/9 Feet Log Veneer Rotary Peeling Lathe with CE ISO

>> Falling Ball Rebound Modulus Plate Soil Parameter Tester Equipment