500/1000/2000kg/H Toilet Facial Soap Production Machinery Laundry Soap Making Machinery

| US$5,500.00-65,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

YM-1000

Capacity

100-300/300-500/500-1000/1000-2000kg/H

Certification

CE, ISO

Condition

New

Control System

PLC Control

Cooling Method

Water Cooling

Heating Method

Electric Heating

Main Material

Aluminum, Carbon Steel, Cast Iron, Stainless Steel

Mould Shapes

Customized, Heart-shaped, Rectangular, Round

Power Source

Electric

Warranty

1year

Name

Soap Making Machinery

Application

Forming Toilet/Laundry/Hotel/Bath Soap Bars

Soap Size/Logo

as Per Your Request

Soap Type

Soap Making Machine Production Line

Advantage

Lower Price/Manufacturer Directly Supply

Logo

Customized Made

Raw Material

Soap Noodles/Oil/Fat/Soda/Caustic

Product Name

Soap Making Machinery

Soap Shape

Oval/Rectangular/Heart or Others

Power

380V/50-60Hz

Materials

Carbon Steel/Stainless Steel

Finished Soap

Toilet Soap/Body Soap/Hotel Soap/Laundry Soap

Key Words

Soap Making Machinery

After Sales Provided

Engineers Come to Guide Installation and Training

Transport Package

Wooden Box

Specification

Easily to operate

Trademark

Yomier

Origin

China

HS Code

8479820090

Production Capacity

20sets/Month Soap Making Machinery

Product Description

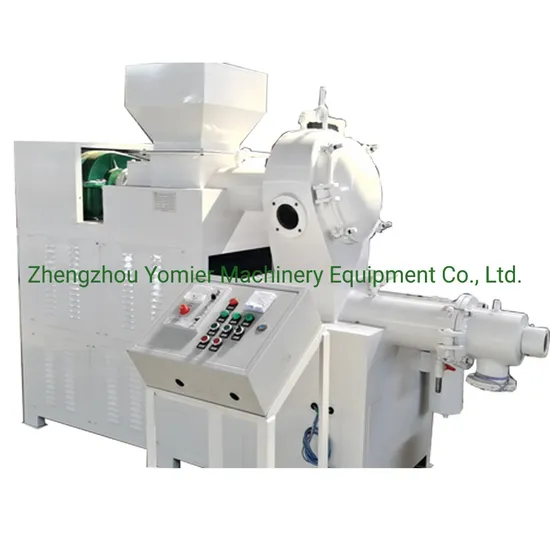

500/1000/2000KG/H Toilet Facial Soap Production Machinery Laundry Soap Making Machinery Main PhotosLayout of Soap Making Machinery

Production flow photos of Soap Making Machinery

Product Description

Introduction of Soap Making Machinery

1. This soap production line take soap noodles(soap bar) as raw materials.2. The production starts with mixing soap noodles/stripes,perfume pigment,essence and,etc.2. Then the mixed soap noodles enters in the three roller mill by conveyor belt, where soap thin sheets are made. 3. The soap thin sheet then converted into desired long strip soap by the vacuum twin screws plodder machine.4. Then the long strip soap are cut into the soap bars required size and shape by cutting machine or toilet soap stamper machine5. Finally, the soap bars gets packed by packing machine if needed.6. Soap bars can be made 15g,20g,30g,60g,120g,200g,260g,and so on

Different capacity of Soap Production Factory

Toilet soap production line: 100/200/300/500/800/1000kg/h

Laundry soap production line:100/200/300/500/800/1000/1500/2000kg/h

Features of Soap Production Factory :1. The finishing lines of Series for Laundry or toilet and translucent soap bring together all components that are most reliable, most durable, supplied by the most famous vendors in the world. 2. The mechanical design is tend to be simplified, more robust, low energy consumption, low off-stream rate, easy to be maintained ,more people oriented and with good view both outside and inside of the machines.

Machine parameter of Soap Making Machinery

| Main machines | Model | Capacity | Specification | Function |

| Soap Mixer | YM-60/70/80 | 70/90/120kg/batch | Depends on the model/capacity | Mixing the material and neat soap, also crushing the bad soap bars. |

| 3 roller miller | YM-S150/S260/S405 | 300/500-1000/2000kg/h | Depends on the model/capacity | rubbing soap material |

| Semi-finished product conveyor | Depends on the model/capacity | convey soap pieces | ||

| Double-screws vacuum soap plodde | YM-C180/219/245/325 | 100-300/300-500/500-1000/1000-2000kg/h | Depends on the model/capacity | vacuum ploddering |

| Vacuum pump | YM-VP001/VP002 | 8/15L/S | Depends on the model/capacity | vacuum bubble pumping |

| Laundry soap bar cutting machine | YM-SC004 | 100-3000KG/H, Depends on the soap plodder | Depends on the model/capacity | cut the soap into different sizes and weight, and print words and logo on the soap bar |

| Toilet soap stamper machine | YM-SPM001/SPM002 | 100-500/500-800kg/h | Depends on the model/capacity | print different shapes toilet soap with different logo |

| Products conveyor | Depends on the model/capacity | Convey products | ||

| Soap chiller | YM-SC001/SC002 | Depends on the model/capacity | auxiliary equipment of the soap printer | |

| Soap packaging machine | YM-CT250/CT320 | Depends on the model/capacity | packing toilet and laudnry soap bars |

Detailed images of Soap Making Machinery

MIXER

Trip grinder

SOAP PLODDER

LAUNDRY SOAP CUTTER

TOILET SOAP STAMPER

Clients' feedback

Clients's Soap Making Machinery For you reference):

Customized made Soap Making Machinery for reference:

Clients visit Us:

Packaging & Shipping

Packing and shipping of Soap Making Machinery :

FAQ

FAQ OF price of Soap Making Machinery

1, Q: Soap industry production process?

A, Basically, the soap production need 2steps:

a, using all kinds of oil&fast as material to produce semi-finished soap noodle;

b, using seme-product soap noodle to produce end bar soap.

2, Q:What is the kinds of the soaps?

A: For convenience, we separate the soap into two kinds, toilet soap for washing hand&taking bath, herbal soap, hotel soap, antiseptic soap are included;

The second kind is laundry soap for washing clothes, etc.

3,Q: What kind of oil is suitable for soap production?

A: All kinds of vegetable oil and animal fats are usable, palm oil, cotton seed oil, tallow oil, coconut oil, sunflower oil, etc.

4,Q: What is the floor of the workshop size?

A: For oil line: 35*7m with height 7m;

For soap noodle line: 25*3m with height 4m.

5,Q: What is the formula?

A: Raw material is oil, caustic soda and salt; semi-product is soap noodle, perfume and color.

Accurate formula based on your local market's request is available after confirmation of order.

6,Q: How about the Engineer and technique support?

A:

1, We would send engineer overseas for machine installation, staff training and production test running, till your own staff can operate the machine well and product out qualified soaps.

2, During the life-span of our machines, we should give consistent technique support and service, and we are pleasure to be on service of you.(24hours on line)

7,Q: If there are spare parts broken,how to solve it?

A: First of all, pls take the pic or make a video to shoe the problem parts,after the problem is confirmed by our engineers, we will send you the spare part for free,,but customers should bare the delivery cost.

>> Fruit Juice Beverage Honeysuckle Grapefruit Juice Soft-Drink for Kids Fruit Juice Beverage

>> Durable Hole Towel Cloth Nonwoven Fabric Making Machine for Operating Rooms

>> 315/433m Wireless Remote Control Transceiver PT2262 HS2272 Receiver Module

>> UHMWPE Environmental Friendly Plastic Construction Pressing Mats

>> 120d 71GSM 100% Polyester Can Be Printed Breathable Shirt Silk Chiffon Fabrics

>> Electric Deep Kneading Massage Machine Foot Massager

>> PTO type sunflower seed husk wood pellet machine

>> Manufactory of Wood Crusher machine

>> Cheap Price Making Mill Normal Specification Waste Recycling Plant Duplex Board Paper Machine 1500-6000mm

>> Maintenance Free Battery Powered Ride on Floor Scrubber for Big Area

>> Commercial Seat Conference Theater Furniture Lecture Room Events Wedding Banquet Auditorium Church Chairs

>> Army Leisure Shoe Military Knitted Fabric Rubber PU Injection Men′s Casual Shoes

>> Trimming Machine with High-Precision Positioning System and Multi-Mold Adaptation Trimming

>> Energy-saving and environmentally friendly aluminum alloy flat door

>> USB Rechargeable Portable Food Plastic Bag Sealer Vacuum Mini Sealing Machines

>> Factory Supplies Screen Printing Ink for Plastic Materials ABS PP PE PVC PET PA

>> oem odm white custom Small black polka dot corrugated cardboard mailer transport box Cardboard delivery shipping box

>> Bolt Nail Packing Machine Carton Box Packaging Counting Machine

>> PC/PMMA/Acrylic/ GPPS/ Ms/ LGP Board Production Extrusion Machine / Extruder Line

>> OEM Compact Crawler Excavators Suitable for Indoor Decoration Projects Pnyme-30

>> High-Strength Gear Housing 7075-T6 Aluminum Metal Precision CNC Machining Part

>> Original Xiaomi Mijia Smart Home Mi Automatic 2500 Pa Strong Suction Wet And Dry Sweeping Robot Vacuum Cleaner 1C Global Version

>> (RAMBO III) The First Blood Movie 3 Fixed Blade Rambo Survival Knife

>> API 15hr Connection Fiberglass Pipe Systems Tube for Oil and Gas Well

>> Premium Quality Wholesale Organic Raisins at Cheaper Price Dried Grape

>> Hot Selling Stainless Steel Crimped Mesh for Decorative

>> New Design Colombia Price 8ton Wire Rope Hoist Manufacturer

>> Volkswagen Sharan/Audi/ Seat/Porchase up Clutch Moon Clutch Cylinder Hydraulic Release Bearings of OEM 006141165c

>> Madly Body Kits for BMW 5 Series F18 Body Kits for BMW F10 body kits for BMW F18 2011-2013 Year Madly style

>> Wamit Waterjet Cutting Machine with 3 Axis Cutting Head