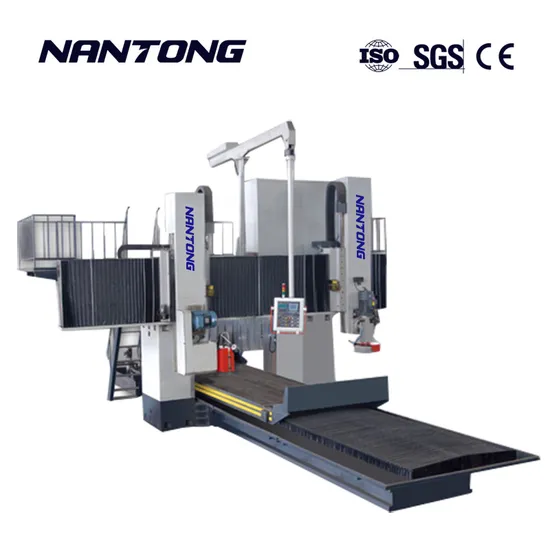

Nantong Industrial Grade CNC Metal Milling Machine

| US$15,900.00-95,600.00 | 1 Piece (MOQ) |

Basic Info.

Structure

Gantry

Milling Cutter Type

Angle Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

CNC

Automatic Grade

Automatic

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

Transport Package

Container

Trademark

nantong

Origin

Nantong

Production Capacity

300 Sets/Year

Product Description

Machine Parameters| Model | Unit | SKX2016 | SKX2500 | SKX3020 | SKX4025 |

| Travel | |||||

| X axis | mm | 2,200 | 2,700 | 3,200 | 4,200 |

| Y axis | mm | 1,600 / 2,000/2500/3000 | |||

| Z axis | mm | 800(1,000-opt.) | |||

| Distance from spindle nose to table | mm | 150 - 950(150 / 1,150-opt.) | |||

| Distance between two column | mm | 1,700 / 2,100/2600 | |||

| Working table | |||||

| Table Length | mm | 2,000 | 2,500 | 3,000 | 4,000 |

| Table Width | mm | 1,600 / 2,000 | |||

| Table Load | kg | 6,000 | 7,000 | 9,000 | 10,000 |

| T- Slot (Width x Number x Pitch) | mm | 22x7x180 / 22x9x180 | |||

| Spindle | |||||

| Spindle Taper | - | BT-50 / ISO-50 / CAT-50 | |||

| Spindle Speed | rpm | 3,000(6,000-opt.) | |||

| Spindle motor(cont./30 minutes rated) | kw | 18.5 / 22 (22/26-opt.) | |||

| Feed | |||||

| Rapid Traverse(X/Y/Z) | m/min | 12 / 12 / 15 | 10 / 12 / 15 | ||

| Cutting feedrate | mm/min | 7,000 | |||

| Accuracy | |||||

| Positioning Accuracy | mm | ±0.005 / 300 ; ±0.015 / Full travel | |||

| mm | P0.03 | P0.035 | |||

| Repeatability | mm | ±0.003 | |||

| mm | 0.025 | 0.028 | |||

| ATC | |||||

| Tool magazine capacity | pcs | 32 (24/40/60-opt.) | |||

| Max. tool size (full pocket/next pockets empty) | mm | Ø125/245 | |||

| Max. tool length | mm | 350 | |||

| Max. tool weight | kg | 20 | |||

| Others | |||||

| Power required | kva | 65 | |||

| Pneumatic input pressure | kg/cm2 | 6.5 | |||

| Machine net weight | tons | 20 / 22 | 22 / 24 | 24 / 26 | 28 / 30 |

| Floor space (LxWxH) | m | 8.5x5.1(5.5)x4.7 | 10.5x5.1(5.5)x4.7 | 12.5x5.1(5.5)x4.7 | 15.2x5.1(5.5)x4.7 |

Machine Configuration

| Automatic lubrication system |

| Spindle oil cooler |

| Air blast through spindle |

| Manual Pulse Generator |

| Working lamp |

| 3-color alarm lamp |

| RS-232 interface |

| Heat exchanger for electrical cabinet |

| Water gun and air gun interface |

| Cutting coolant system |

| Twin auger chip removal system |

| Belt type chip conveyor with cart |

| X axis Heidenhain Linear Scale |

| Sub-table |

| 3 axes manual pulse generator for mold processing |

| Coolant through spindle at 20/40/70 bar |

| Coolant through tool holder interface |

| Air conditioner for electrical cabinet |

| Transformer |

| Oil skimmer |

| Oil mist collector |

Company Introduction

NANTONG YIJI MACHINERY CO., LTD

Nantong YIJI Machinery Co., Ltd was founded in 1988, specializing in the manufacturing of move column CNC machine centers, floor type boring machines, CNC gantry milling machines, automatic solutions, and professional machine tools. Nantong YIJI Machinery Co., Ltd integrates the business concept of 'Quality is essence, excellence, full participation', continuously enhancing the 'YIJI' machine brand quality. With specialized design, mature production workmanship, strict QC management, quick integrated solutions, and excellent after-service support, we have won the trust of numerous customers. Our market share has expanded significantly, and our products, known for their variety and comprehensive range, have enjoyed robust sales across 30 countries in Europe, America, and Southeast Asia, earning an excellent reputation. Our company holds import/export rights, has obtained export product licenses, CE certification, and has passed ISO9001 quality system certification.

Innovation is endless. Techniques change the future. We are eager to provide you with our professional technology, top-quality machines, and unparalleled service.

Our Service

Warranty & After-sale service

1. 24-hour technical support available via email or telephone.

2. We offer additional accessories for the machine and can create customized programs based on your drawings. Custom or special designs are available.

3. All of our products come with a 12-month warranty.

4. Damage caused by human error is not covered.

5. We provide materials and technical support to help our customers resolve any issues.

We will cover the delivery charges for repair, return, or replacement cases.

We welcome your inquiries!

>> Decorative perforated mesh fence rectangle hole stainless steel perforated mesh plate

>> Advanced Heating System Lab Rubber and Plastic Two Roll Open Mixing Mill

>> Fruit Juice Beverage Honeysuckle Grapefruit Juice Soft-Drink for Kids Fruit Juice Beverage

>> Durable Hole Towel Cloth Nonwoven Fabric Making Machine for Operating Rooms

>> 315/433m Wireless Remote Control Transceiver PT2262 HS2272 Receiver Module

>> UHMWPE Environmental Friendly Plastic Construction Pressing Mats

>> 120d 71GSM 100% Polyester Can Be Printed Breathable Shirt Silk Chiffon Fabrics

>> Electric Deep Kneading Massage Machine Foot Massager

>> PTO type sunflower seed husk wood pellet machine

>> Manufactory of Wood Crusher machine

>> Plastic Pallet for Efficient Paper Storage Solutions Replaceable Wooden Pallets Made in China

>> Metal material flaw detector ultrasonic crack detectors for welding inspection price

>> Faf Series Hollow Shaft Flange Mounted Parallel Shaft Helical Geared Motor

>> Durable Interlocking Plastic PP Garage Floor Tiles for Car Washing

>> Heavy Duty Slide Out Seasoning Organizer for Kitchen Cabinets Pull Out Spice Rack Organizer for Cabinet

>> Aluminum Glass Sliding Window building glass windows Sliding Windows

>> M003 Heavy Duty Commercial Treadmill

>> HC-S104 High Quality Full-featured Medical Nursing Training Manikins Patient Care Training Dummy

>> Drink with a Straw Crazy Sour Fruit Powder Candy

>> REVO Timing Chain Tensioner For SAAB 2.0L/2.3L oe no.9139130 TN1102

>> Yamane 30FT CE Certified Hard Top Center Console Aluminum V-Bottom Fishing Boat Speed Boat

>> Wholesale Jars Glas Srooster Ball Jarsbottles 50ml 60ml 100ml 250ml Personalized Wine Small Crystal Zinc Alloy Wooden Natural Synthetic Cork Stopper

>> Free Nonstick Disposable 100 Pieces Airfryer Parchment Baking Paper Square Round Airfryer Paper 20-24cm 8inch 8-10zoll

>> 430 high pressure mine powder coke coal carbon black coal ball briquette press machine line

>> China Automatic HDPE PP PVC PC ABS Plastic 100ml 500ml 1L 2L Bottle Making Maker Blower Blowing Extrusion Extruder Extruding Blow Molding Moulding Machine

>> Impact Drill New Structure Impact Screwdriver 20V

>> Sliver Color Micro Orthopedic Bone Drill for Surgical Surgery

>> 12′′ 14′′ 16′′ 18′′ Carbon Steel Kids Balance Bike High Adjustable Children Bicycle Girls Toddler Cycle Bike for Kids

>> Stainless Steel 3D Chemical Blender Powder Mixer Mixing Machine with CE

>> Cargo Service Shipping Freight From China