10L Vacuum Emulsifying Turbo Cream Mixer Cosmetic Machine Supplier in Thailand Product Turkey Body Lotion Emulsifier Machine

| US$6,000.00-13,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

AVE

Application

Liquid, Viscous Fluid, Liquid with Suspended Solids, Powder, Viscous Fluid, Liquid, Granules, Cream and Lotion, Cosmetics Cream

Application Area

Chemical, Daily Chemical, Food, Pharmaceutical, Cosmetic

Certification

CE, CE, ISO, SGS

Condition

New

Control System

Button Control

Cooling Method

Water Cooling

Heating Method

Electric Heating/Steam Heating, Electric Heating

Main Material

Stainless Steel

Mixing Capacity

50-5000L

Mixing Drum Shape

Cylinder, Frame

Speed Control

Single Speed

Speed Range

60 R/min & Above

Stirring Type

Spiral, Stirring

Temperature Control

With Heating

Working

High Speed Mixer

Mixer Type

Homogenizer

Operating Type

Continuous Operating

Layout Type

Hydraulic

Material

SUS304/SUS316(Material Contact Part)

Structure

Water Tank, Oil Tank, Emulsifying Tank, Platform a

Electric Cabinet

PLC/Button Control

Agitator

0-75 Rpm, Frame Wall Scrapping Mixing with Propell

Lifting System

Hydraulic Lifting

Vacuum System

Water Cycle Vacuum Pump

Homogenizer

0-3600rpm

Components

Siemens, Delta, Schneider, Delixi etc

Function

Mixing, Homogenizing, Emulsion

Discharge

Tilting Discharge and Bottom Outlet

Transport Package

Wood Case

Specification

2000*800*2500mm

Trademark

Ailusi

Origin

China

HS Code

8479820090

Production Capacity

100sets/Month

Product Description

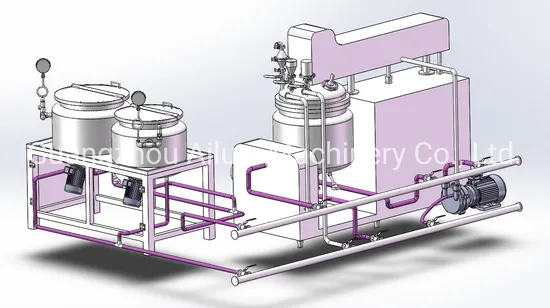

PProduct Description: The machine is suitable for the production of various kinds of paste, cream products in cosmetic factories and pharmaceutical factories. Specially designed for the production of stable emulsions creams, milk, gels, balms, lotions, ointments, toothpaste, etc. having extremely small particles for chemical, cosmetics, pharmaceutical, and food industriesStandard configuration- Emulsifier, water phase tanks, oil phase tank - Vacuum pumps and sync solenoid valves - Emulsifier and material filter - Hydraulic lifting system and mixing system- Stainless steel platform- Inverter and electrical control box

Working PrincipleThe materials in the water-phase tank and oil-phase tank are heated up and stirred. After they are thoroughly mixed, they will be transferred to the emulsifying tank by the vacuum pump. The material will be stirred by the upper part of the central paddle, combined with the PTFE scraper sweeping the wall, the material will be stirred thoroughly and meanwhile be pushed down to the emulsifier at the low part of the central axle. With a very high-speed emulsifying effect, the material will be seriously cut, sheared, and cracked into 200nm - 2um particles. The bubbles that appear during the process will be sucked out promptly in the vacuum status in the tank.

Technical Parameters:

| capacity (L) | Agitator power (kW) | Speed (rpm) | Homogenizer power (kW) | Speed (rpm) | Oil/Water tank (L) | Agitator power (kW) | Speed (rpm) | Hydraulic (KW) |

| 50 | 1.5 | 0~75 | 2 | 0~3600 | 20/45 | 0.37/0.37 | 0~1440 | 0.75kw |

| 100 | 2.2 | 0~75 | 3 | 0~3600 | 40/90 | 0.55/0.55 | 0~1440 | 0.75kw |

| 200 | 3 | 0~75 | 5.5 | 0~3600 | 80/180 | 0.75/0.75 | 0~1440 | 1.1kw |

| 300 | 4 | 0~75 | 5.5 | 0~3600 | 120/270 | 1.1/1.1 | 0~1440 | 1.5kw |

| 500 | 4 | 0~75 | 7.5 | 0~3600 | 200/450 | 1.5/1.5 | 0~1440 | 1.5kw |

| 1000 | 5.5 | 0~75 | 11 | 0~3600 | 400/900 | 2.2/2.2 | 0~1440 | 2.2kw |

| 2000 | 7.5 | 0~75 | 15 | 0~3600 | 800/1800 | 2.2/2.2 | 0~1440 | - |

| 3000 | 11 | 0~75 | 18.5 | 0~3600 | 1200/2700 | 3/3 | 0~1440 | - |

Main features:

1) Consist of the main emulsifying mixer, water pot, oil pot, vacuum pump, etc

2) Ointment making machine adopts advanced world famous brand components in pneumatic parts, electric parts, and operation parts.

3) High-quality SUS304&316L material, internal and external mirror polish of homogenizer mixer.

4) High effection homogenizer, 2μm smooth finish

5) Vacuum emulsifying mixer machine applies to cosmetics, pharmaceutical, food, etc industries

Details pictures:

Factory:

Project:

>> Aluminum Punching Parts

>> HRA-II TCM diagnosis and treatment equipment for diabetes Cardiovascular disease and thrombosis

>> Custom-Made Hydraulicfloor to Floor Car Elevator Scissor Car Lift

>> Boshida Customized Auto Focusing 300X200mm Mrasure Range Image Measurement Microscope

>> Sustainable Oxford Fabric Furniture Cover Textiles for Woven Bag Lining Tent

>> Electric Foldable Space Saving Half Body Jade Rollers Massage Table Bed

>> Rubber Wheel with Bearing Dac37740045 Wheel Bearing for Ford Focus

>> 6m Single Mast Aluminum Alloy Aerial Work Platform Vertical Lift with High Efficiency

>> Simple Design Wrought Sheet Iron Double Door arched wrought iron door

>> Cast iron kitchenware enamel nonstick shallow casserole

>> Industry-Leading Quality Harrow Plough Plow Tilling Harrow Disc

>> Korean Premium Extra Big Sizes Qualiti Babi Baby Panty Diaper Heart Baby Elastic Paper Boy Swimwear Ultra Thin Diaper

>> Single Head Computer 12 Needle Industrial Sewing Machine Hat Garment Flat Embroidery Machine Computerized

>> japanese fishing line fluorocarbon super strong monofilament fishing line

>> Professional Innolux LCD screen with 7.0" 800*480 resolution TFT LCD Display

>> 100ml Jelly Nata De Coco Meat Fruity Juice Drink Beverage in Bottle

>> Wholesale Hotel Design Modern Wall Mounted Cabinet Furniture Ceramic Basin LED Mirror Bathroom Vanity Customized High Quality Sanitary Vanity Set

>> 6X3w Outdoor LED Landscape Spot Lighting

>> 4040 reverse osmosis membrane shell of water treatment machinery for seawater

>> High Precision CE Machine Center Fanuc/Siemens/Mitsubishi Controller Gantry CNC Vertical Milling Machine

>> Large Workpiece Processing Lathe Ck6180*1500 Ck6180*3000 Ck6180*4000 CNC Machine Tool

>> Disposable blue non Sterile protection clothing Non Woven elastic and knitted cuffs isolation Gown

>> Automotive Engine External Cleaning Agent Raw Material Automotive Oil Cleaning Agent

>> Hotel Square Head Wooden Coat Brush with Hanging Strap

>> Outdoor Windproof Waterproof Plain Nylon/Polyester Ripstop Oxford Cloth PVC Coated Vinyl Fabric for Truck Cover Bags, Luggage Camping Tent

>> Plastic PP Board Panel for Pigs

>> Air Cooling Plastic Recycling Machine

>> 30-45 Business Days After Confirmed by Express, 5-7 Days. Sea, 25-30days Designer Women Bags

>> 18X10W LED PAR Zoom Light RGBW 4in1 5kg/PCS Lightweight

>> Professional Instrument Trimble S7 Autolock 1″ Total Station for Construction Survey