4 Axis Linkage Intelligent CNC Woodworking Lathe

| US$17,700.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

WS523

Voltage

380V

Tool Holder

Double-tool Holder CNC Lathe

Automatic Grade

Automatic

Precision

High Precision

Setting Mode

Floor-type

Controlling Mode

CNC

Power Source

Electric

Processing Accessory

Chuck CNC Lathe

Certification

CE, ISO

After-sales Service

12 Month

Wood Piece

1200*300mm

Control

CNC

Pressure

0.4-0.8MPa

Spindle

7.5kw*2

Power

5.5 Kw

Transport Package

According to Customer Requirements

Specification

L523AX

Trademark

OEM

Origin

China

HS Code

8465910000

Production Capacity

200 Sets Per Year

Packaging & Delivery

Package Size

275.00cm * 200.00cm * 150.00cm

Package Gross Weight

1800.000kg

Product Description

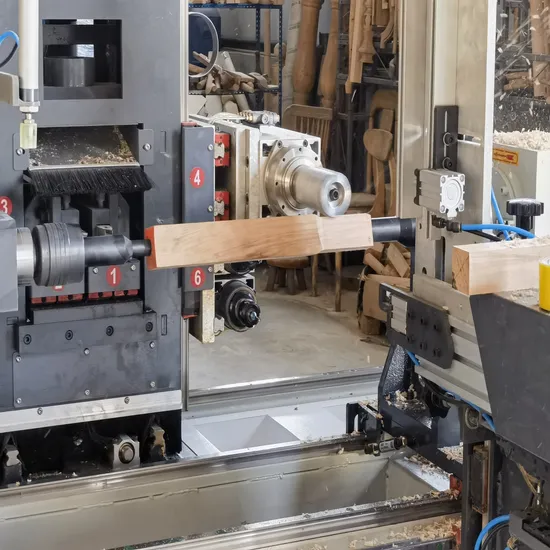

Product Description4 Axis Linkage Intelligent CNC Woodworking Lathe

(Milling+Rotary Engraving+Flat Engraving+Peculiar Processing)

Popular and Highly trusted in Ukraine, Russia, Japan, Korea, Europe and the United States .

| Model | WS523 |

| Max size of work piece | 1200mm*300mm |

| Max size of auto loading rack | 1200mm*150mm |

| CNC controller | NCstudio |

| Control form | CNC-PC |

| Driver /motor | Brand :DELTA |

| Servo Motor Power | X:1kw, Y:1kw,Z:1kw, A:0.75kw |

| Linear rail | Brand:HIWIN |

| Spiral screw | Brand: TBI |

| Inverter | Brand: HAPMONT |

| Spindle motor | 7.5kw*2pcs, 4.5kw*2pcs |

| Turning cutter Power | 5.5kw/4grades |

| Sander power | 1.1kw |

| Lubrication system | Electric automatic lubrication pump |

| Electrical system components | CHNT |

| Structure | Heavy duty overall welding heat treatment bed |

| Voltage | AC380V/3PH/50HZ-60HZ |

| Pressure | 0.4-0.8 mpa |

| Weight | 1800kg |

| Overall size | 2750*2000*1500mm |

Related Machines

CNC Curve Sawing Milling Machine

| Model | WS525 |

| Max.Size of work-piece | 3700mm*1830mm |

| Max.working thickness | 150mm |

| Max processing speed | 0-10m/min |

| Software | Artcam,Computer Aided Design(CAD) |

| Gear rack | High precision module rack |

| Saw Head Spindle motor | Motor : 7.5KW *2 pcs |

| Drill Spindle motor | 9KW*1 pcs |

| Ball screw | Taiwan TBI |

| Frequency converter | 24KW high frequency converter, Brand :HPMONT |

| Air pressure | 0.6-0.8 mpa |

| Gross weight | 3500KG |

| Servo motor | Taiwan DELTA servo motor |

| Liner rail | Taiwan HIWIN |

| Lubrication system | Electric lubrication pump |

| Electrical system components | CHNT |

| Overall size | 8800*4700*2100mm |

Turning & Milling Compound Four Axis Multi Process Maching Center

Process chair leg/arm, dining table leg, sofa leg, billiard leg etc.

Automatic loading and unloading,automatic polishing/grinding,

turning,milling,saw,chamfer,mortise ,drill vertical/inclined hole,slot,grooving and so on.

| Model | WS753AF |

| Max size of work piece | 1500mm*300mm |

| Max size of auto loading rack | 1500mm*150mm |

| CNC controller | Nc Studio |

| Control cabinet | air-cooled CNC cabinet |

| Contral form | CNC-PC |

| Driver /motor | Brand :DELTA |

| Servo Motor Power | X:2kw, Y:1.5kw,Z:1kw, A:0.75kw |

| Linear rail | Brand:HIWIN Width: X:30mm, Y/Z:25mm |

| Spiral screw | Brand: TBI |

| Inverter | Brand: HAPMONT |

| Spindle motor | air cooling spindle Power : 6kw*4pcs =24kw |

| Turning cutter Power | 5.5kw/4grades |

| Column milling Power | 5.5KW |

| flat sanding Power | 1.5KW |

| Circular Sanding Power | 1.1KW |

| Saw power | 3KW |

| Lubrication system | Automatic Electric lubrication pump |

| Electrical system components | CHNT |

| Structure | Heavy duty overall welding heat treatment bed |

| power | CVT |

| Voltage | AC380V/3PH/50HZ-60HZ |

| Pressure | 0.4-0.8 mpa |

| Weight | 3200kg |

| Overall size | 4200*2200*2200mm |

Five Axis Cross Knife Changing Machining Center

| Overall Size | 4500*2200*2200MM |

| Bed | 5 Side Milled,Complete welding, heat treated |

| Working Size | 600×600×2 |

| Control System | RTCP 5 Axis CNC Control |

| XYZAB | X:2400mm,Y:350mm,Z:450mm,A:±180,C:00 |

| Transmission | Imported large modulus high precision helical rack Z axis :TBIball screw,CSK linear guide |

| 4 Axis Reducer | Precision low return |

| Spindle | 4.5-7.5KW Air Cooling Cross (18000R/M) Line Auto Tool Changer 8 |

| Drive System | Servo Motor |

| Cabinet | Independent Air Cool CNC |

| Voltage | AC380V±10% 50/60Hz |

| Air pressure | 0.8MPa |

| Weight | 3200KG |

5 Axis Woodworking Machining Center

| Engraving Size | 1300*2500/1212*1212*2 |

| Spindle | Frequency Water Cooling brush less motor 6000-24000RPM |

| Working Speed | 1000-1500MM/Min |

| Resolution | 0.01MM/Step |

| Spindle Power | 1.5KW/2.2KW/3.0KW7.5KW/9.5KW(Optional) |

| Tool | φ3.175mm/φ4.0mm/φ6.0mm/φ12.7mm ISO30/BT40 |

| Command | hpgl gcode tap txt plt uoo eng |

| Power Consumption | 0-15000W |

| Voltage | AC 220V50Hz 380V50Hz/60Hz |

CNC Double End Tenoning and Mortising Machine

| Spindle Speed | 8000-12000RPM |

| Max Working Length | 2000MM |

| Min Working Length | 20MM |

| Max Working Thickness | 80MM |

| Max Working Width | 180MM |

| Max Tenon Length | 40MM |

| Spindle Motor | 4.5KW*2 |

| Horizontal Angle | -13° +35° |

| Total Power | 15KW |

| Dust Collector | 100MM*4 |

| Working Pressure | >0.6mp |

| Weight | 2100kg |

CNC Mortising Machine/CNC Tenoning and Mortising Machine

| Max Stroke | X:1400MM,Y:1700MM,Z:200MM |

| Max Working Width | 150MM |

| Max Return Speed | 40M/Min |

| Spindle Speed | 1800RPM |

| Motor | 3.5KW*4 |

| Working Air Pressure | 0.5-0.8MPA |

| Voltage | 380V |

| Axis Distance | 220MM |

| Servo Motor | 2.0KW*1,1.5KW*2 Taiwan HUST CNC |

| CNC Controller | TAIWAN HUST CNC |

| Weight | 1500KG |

Multi-axis multi-function Tenoning and Mortising machine Main functions: male tenon, female tenon, 45 degrees interlocking tenon, lattice shoulder V tenon, palm corner tenon, hand tenon, shoulder tenon, drawer dovetail tenon, oblique slot, round slot, slot drilling, support mapping process

| Working Height | 10-90MM |

| Work Table Effective Travel | 2200MM |

| Hand Wheel Knife Setting Apparatus | 1 Set |

| Display | Windows System 15 Inch |

| Reducer | Planetary |

| Rail | High Precision Linear |

| 1.5 Skewed Teeth Rack | High Precision Grinding |

| Frequency Changer | Constant Power Changer |

| Servo Motor & Drive | 0.75KW*3 PCS |

| High Speed Spindle Motor | 4.5KW*1,3.5KW*3 |

| Spindle | Air Cooling |

| Electrics | CHINT |

| Bed Body | Aging Treatment 5 Side Machining |

| Total Power | 17.5KW |

| Weight | 900kg |

| L*W*H | 3600*1600*1500MM |

CNC 5-axis solid wood drilling and milling machining center

| Max Working Length | 1000MM |

| Max Rotating Diameter | 280MM |

| Spindle Quantity | 8 PCS |

| Spindle Power | 3.7KW*4+5.5KW*4 |

| Control System | TAIWAN LNC |

| Servo Motor | TAIWAN DELTA |

| Guide Rail | TAIWAN HIWIN |

| Voltage | 380V |

| Total Power | 45.5KW |

| L*W*H | 5000*2900*2450MM |

| Weight | 4800KG |

Multi Functional Integrated Double Tool CNC Woodworking Lathe

Turning and milling carving (round carving)

| Model | WS315K | WS415K | WS425K |

| Working Size | 1500*300MM | 1500*400MM | 2500*400MM |

| Electric Motor | 5.5KW (Customized) | ||

| Control | CNC/Handle | ||

| Power | CVT | ||

| Feeding Speed | 3000MM/Min | ||

| Voltage | 380V 50HZ 3 Phase | ||

| L*W*h | 2750*1300*1650 | 2700*1400*1750 | 3700*1400*1750 |

| Weight | 1500KG | 1700KG | 2100KG |

Single Axis Intelligent Double Tool CNC Woodworking Lathe

| Model | WS315S | WS415S | WS425S |

| Working Size | 1500*300MM | 1500*400MM | 2500*400MM |

| Electric Motor | 5.5KW (Customized) | ||

| Control | CNC/Handle | ||

| Power | CVT | ||

| Feeding Speed | 3000MM/Min | ||

| Voltage | 380V 50HZ 3 Phase | ||

| L*W*h | 2750*1300*1300 | 2700*1400*1400 | 3700*1400*1400 |

| Weight | 1450KG | 1650KG | 2050KG |

CNC 4 axis milling & drilling machining center

| Max Working Size | 1220*2440mm |

| Max Working Thickness | 150MM |

| Spindle Quantity | 3 |

| Spindle Motor | 7.5KW*2+9KW ATC |

| Linear Tool Changer | 4 Pcs |

| Working Speed | 0-10Meters/Min |

| Air Pressure | 0.6-0.8MPA |

| Servo Motor | Taiwan Delta |

| Guide Rail | Taiwan HIWIN |

| Voltage | 380V |

Company Profile

Specialize in research & development, production, sales of sawmills and the relevant fittings SINCE 1988

We have serves 11,000 enterprises and our products have been exported to over 60 countries in the world.

Sawmill & Kilns & Pallet & Biomass & Forestry & Recycling & Woodworking

Sincerely welcome worldwide distributors to join us!

>> Professional Master 20PCS Hydraulic Dough Divider Rounder Bakery-Equipment Price

>> Industry Paper Collecting Sorting Machine Automatic Paper Collator Machine Gathering Collating Machine

>> Estop China 3 Axis CNC Vertical Metal Milling Machine for Mechanical Processing

>> Construction Equipment Chassis Giga 10m3 350HP Concrete Construction Truck

>> Plastic Mixer with Mix Propeller Dental Resin Production Line Propellant Mixer Explosive Kneading Machine

>> New Condition and After-Sales Service Provided Circular Saw Blade Sharpening Machine

>> The Aluminum Frame HEPA/HVAC Air Dust Cotton Fabric Filters Filter

>> 0-150mm IP54 Absolute Big Screen Digital Vernier Caliper 0-6"

>> Wholesale Custom Size Breathable Hotel Bedding Set White Cotton Bed Sheet

>> Anti-Reflective Coating on Lens Surface Minimizes Unwanted Reflections

>> Hard Plastic Granulator/Plastic Crusher of Recycling Machine with Ce/ PC52120

>> Reliable Timber Crusher for Fast and Effective Wood Shredding

>> Hot Sale Sf 12ton Excavator Attachments Digging Bucket Tilting Bucket

>> Custom Adjustable Molle Multicam Men Micro Oxford Polyester Vest Tactical Chest Rig Bag

>> XIAOMI MIJIA Lint Remover Clothes fuzz pellet trimmer machine portable Charge Fabric Shaver Removes for clothes Spools removal

>> Galvanized Corrugated Gi Steel Sheet Perforated Mesh Wind Dust Fence

>> ATX 700W High Effciency Gold 80 Plus Power Supply

>> Fd/SD/Br DTY FDY Dyed Round Bright Ecdp/Cdp Polyester Filament Special Cationic Semi Dull + Cation SD+CD Yarn for Knitting and Weaving Garment Fabrics

>> Original Hgsr102j Mitsubishi Electric Motor Hg-Sr102j AC Servo Motor

>> Factory Direct X6 Mini Handheld Game Console 3.5′′ Large Screen Retro Arcade 3D Dual Joystick Nostalgic Gaming Device with 6000+ Games

>> Fresh Red Onion Importers Fresh Vegetables Onion

>> 300 GSM Tshirt Men′s 100% Cotton Mock Rib Neck Oversize Drop Shoulder T-Shirt Blank Streetwear Heavyweight Plain T Shirt for Men

>> Mini Wireless Bluetooth Keyboard with Built-in Card Slot for Computer Office

>> CNC Fabrication Service Custom CNC Machining Precision Parts CNC 5 Axis Machining Center Micro Machining Mechanical Parts Fabric

>> Huayu SMD5050 60LEDs 10IC DMX512 RGB LED Flex Decoration Neon Strip Light

>> Concrete Cone Slump Tester Slump Cone Test Apparatus

>> Wholesales Luxury Winter Warmth Scarf - Popular Brand, Classic Logo Design, Soft Material

>> Genuine Car Bumper For Benz E Class W213 To 21 E63S AMG Wide Body Kits Grille Fender Headlight Taillight Rear Diffuser With Tips

>> Table Runner

>> LED Waterproof Light GS