Metal Sheet Cutting Machine Steel Deck Roll Forming Machine

| US$20,000.00-22,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

NB-1000mm

Tile Type

Colored Steel

Certification

CE, ISO

Condition

New

Customized

Customized

Usage

Roof, Wall, Floor

Transmission Method

Machinery

Color

Green/Blue/Yellow/as Client Like

Woking Speed

0-15m/Min

Drive Style

Gear Box / Gear / Chain

Raw Material

PPGI/PPGL/Gi/Gl/Alumunium

PLC

Orignal Taiwan Delta/Siemens/ Schneider

Base Frame

350h/400h/500h Steel Beam Weld

Decoiler

Manual Type 5t Capacity with Brake System

Cutting Type

Eletrical Motor Drive/Hydrualic Type

Cylindar

Hob High Strengthen

Guarantee

2 Years

Power

11kw

Motor

Shanghai Lichao Brand

After-Sale-Service

Online 24hours/Field Support

Hydraulic System

4.0kw Motor with Cooling Fan

Side Plate

18/20/22mm Thickness

Transport Package

Plastic Packing & Wooden Case Packing

Specification

8000*1600*1000mm

Trademark

Noble

Origin

Hebei, China

HS Code

8455221000

Production Capacity

500sets/Year

Product Description

Metal Floor Deck Profile Roofing Sheet Roll Forming Machine

Roofing Sheet Tile Roll Forming Machine is one of most popular metal building material making machines,it can produce many kinds of trapezoidal tile/panels,like Ag panel or PBR/R panel,which can be widely used in many scenes,like school,gym, warehouse,etc.

1. Component line1000 Roof Panel Cold Roll Forming Machine

| No. | Name | Unit | Qty |

| 1 | Man-made uncoiler | set | 1 |

| 2 | Main machine for roll forming | set | 1 |

| 3 | Control system | set | 1 |

| 4 | Hydraulic system | set | 1 |

| 5 | mold pressing machine | set | 1 |

| 6 | Blade | set | 1 |

| 7 | Receiving table | set | 1 |

Product parameter

Series | Details | Parameter |

| ProducT | Raw material | PPGI /PPGL |

| Material thickness | 0.25-0.8mm | |

| Product cutting length | Adjustable | |

| Coil ID | 508 mm | |

| Coil width | 1250 mm | |

| Coil weight | 5T | |

| Decoiler | Work type | hand type |

| Structure | Steel channel for basic frame | |

| Loading capacity | 5 Tons | |

| Coil inner diameter | 550-610 mm(adjustable) | |

| Max coil width | 1250 mm | |

| Roll forming machine | Feeding device | Platform, the width is adjustable |

| Roller stations | 16 stages The distance between 2 stages is 443mm | |

| Roller shaft | Shaft material: 45# steel | |

| Shaft diameter: φ70 mm | ||

| Roller | Roller material: 45# steel | |

| Roller spacer | Anti rusty treatment | |

| Work speed | 25m/min | |

| Main structure | Middle plate weld with structure | |

| Motor power | 5.5KW ,SHANGHAI LICHAO BRAND | |

| Transmission | 1.0INCH CHAINS | |

| Machine basic frame | 400# H steel welded with diagonal bracing inside | |

| Bearing | Chinese famous brand: Harbin | |

| PLC control system | Frequency brand | Delta (original) |

| PLC brand PLC | Delta (original) | |

| Screen type | Touch screen also have button | |

| Screen language | English / Chinese/Arabic | |

| Low voltage apparatus | TAIWAN DELTA | |

| Encoder | Omron | |

| Function | Cutting to length, quantity and work speed control. | |

| Hydraulic system | Work type | Hydraulic cutting |

| Driving type | By pillar type cylinder | |

| Hydraulic motor power | 4.0KW | |

| Cutter material | Cr12 | |

| Cutting length tolerance | ±1-3mm | |

| Product collect table | Length | 3m |

| Width | 1.3m | |

| Structure | Shaped steel welded | |

| Machine weight | Around 4Tons | |

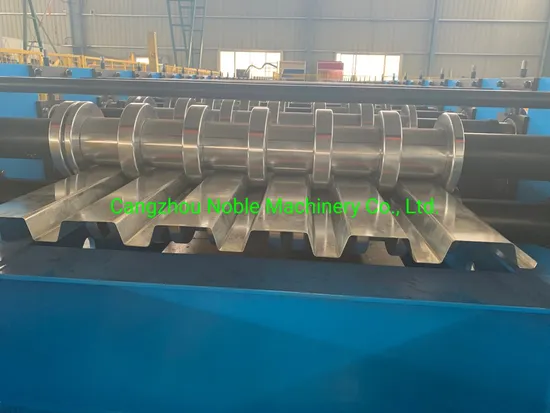

Detailed photo

Decoiler ( Selectable configuration ):

Optional configuration ): Hydraulic decoiler; Loading Lecel: 5tons(common), 8tons, 10tons, 15tons or as requirement;

Loading Width: Max. 1250mm or 1450mm (common);

Loading Inner Diameter: φ450-550mm;

Loading Outer Diameter: Max. φ1500mm

Forming station : With feeding material guide, body frame made from H450 type steel by welding Side wall thickness: Q235 t30mm ; Tie rod:ф22 Galvanized Rollers manufactured from Gcr15/Cr12 steel,CNC lathes,Heat Treatment,hard Chrome Coated with thickness 0.04mm,surface with mirror treatment The warranty for the rollers is 2 years Shafts Diameter=ф90 mm,precision machined Gear/Sprocket driving,about 21-step to form(19-step to form and 3 step for final shaping). Main Motor=18.5KW , Frequency speed control Speed redcucer motor:K series; Size changing motor:6pcs, Automatically controlled by PLC Programing. Sliding block:150*150mm; All the screw bolts with grade 8.8 Real forming speed 20m/min (depending on the number of punching holes)With squareness roller setup

Post Hydraulic Cutting Device Post to cut, stop to cutting,Three pieces type of cutting blade design, no blanking Hydraulic motor:5.5 KW ; Cutting tool material: Cr12MoV The cutting power is provided by the main engine hydraulic station

PLC Controller & Hydraulic System

Collect Product Table 1. Automatic Stacker (optional configuration)--Length: According to customized;

2. Manual Simple collecting product table (standard configuration)--Length: 3m(common) or as customized.

Product feature

1 More efficient and accurate execution of production orders; 2. High equipment reliability; 3. Little waste of materials and energy; 4. High productivity; 5. High quality materials, get a longer service life; 6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to ensure that customers can get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life of the roll; 7. Customized coil processing solutions to solve all aspects of technical problems.

Why Choose this machine? 1. Lifetime seivices2. Introduced Mitsubishi PLC with touch screen to machine controll system.3. One worker operation (minimum) 4. Lifetime>10years: roller cover with 0.05mm chrome72mm diameter solid steel shaftCutting blade with heat treatment. 5. Cr12 mould steel cutter with quenched treatment. 6. Product cut-to-length.8.Technician overseas installing and training available After Sales Service

1. Engineer will give free training lessons to labors in buyer's factory. 2. The Buyer need buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for engineer. 3. During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by incorrect operations, we will provide the buyer spare parts at cost price. 4. We will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide

Packaging & Shipping

Company Profile

Cangzhou Noble as a professional manufacturer of ROLL FORMING MACHINE, we use AUTO CAD design software. With more than 16 years of experience and strict quality control, our products meet international standard. We are the leading manufacturer of ROLL FORMING MACHINE in CHINA.

Our company Sell machinery from 2011 years, manufacture all kind of machinery: Roof Tile machinery, wall panel machinery, roofing corrugated sheet machinery, floor deck machine, C&Z Purline machine, highway guardrail machine, EPS/Rock wool Sandwich panel line, Container board machine, Roll shutter door machine, Down spout machine and Steel bar straightening machine, PPGI/GI/GL Coils, Prefabricated container house Etc. All our clients are satisfied with the workmanship and performance of our machines because our company is accompanied with sound infrastructure and qualified team, Our company prime mission is to provide superior quality industrial machines that are efficient, highly productive and durable.

All our efforts are resulted in to the growth at par excellence and also company started getting recognized as an organization compassionately devoted to the policy of "Quality" with "VALUE FOR MONEY".

Exhibition & Client Visit

Sales Network

Our products are sold at home and abroad.

We are looking forward to forming successful business relationships with new clients around the world in the near future.

FAQ

.How to play order :

Inquiry---confirm the profile drawings and price---confirm the PI---arrange the deposit ---we start producing

What can we do if the machine broken?

The machine will be tested before shipment with coil, ensure everything is ready 2.We will prepare some spare parts along with the machine, ensure our customer can solve the issue in a shortest time.Both the sale person and technician can give you the service overseas and make training for the workers,the sale person can make translation, so that the installation and training will be more clear and easily.

Guarantee

Lifetime maintenance guarantee.We offer 2 years guarantee

*After-sales

To give you the best after-sales service, the first give you video call with professional technicians , the second we send technicians to your country to repair the machine,

The buyer shall bear all expenses, including visa, round-trip airfare and suitable accommodation, and pay the salary of usd 100 / day.

.Contact us:

If you want to get more pictures or videos of the machines, feel free contact us.

We will give you the best experience!

Website:noblemachine.en.made-in-china.com

Factory Address:105 National Road, Botou , Cangzhou City , Hebei Province, China

>> Sesame Coffee Plam Paddy Carob Rice Bean Seed Destoner Machine

>> 15mm Wholesale Silvery Aluminum Fine Mist Spray Pump Easy Perfume Bottle Mist Sprayer Pump

>> Round Base 360 Photobooth Selfie Spinner Camera Ipadselfie Rotating Automatic for Party

>> Yyc China CNC Non Woven Geotextile Fabric Layer Auto Cutter Cutting Machine

>> Stainless steel Gun Shaped Folding pocket survival knife

>> High Speed EDM Erosion Molybdenum Wire Cutting Machine Dk7763

>> Car mudguard for a21 chery a5 cowin Auto parts black fender

>> Aokol -35c Low Temp 15kw Air Water Heat Pump, R32 WiFi Controll Heat Pump, European Market Floor Heating Central Air Conditioning with CE RoHS.

>> Smart Micro LED Projector with WiFi for Movies and Presentations

>> JOHNCOO Saltwater 160g 200g Luminous Reaction Metal Jigs Jigging Fishing Lure

>> New Distributor Fits Nissan 240sx D21 Pickup 1989-1996 2.4 4-Cyl 22100-40f00

>> Agricultural Implement Hand Push Corn Harvester Mini Corn Maize Harvesting Machine

>> HOWO 20cbm Heavy-Duty Concrete Mixer Truck for Sale

>> 220X170mm Infrared Heating Burner Replacement Parts with Nozzle

>> Sialwings front pocket new Arrival 2022 style cotton polo shirt for men

>> Goldencup Single PE Coated Paper Bowl Cup Making Forming Machine Sold 80 Countrys High Speed Automatic Forming Paper

>> Meetyou Machinery China High Quality PVC Wall Panel Ceiling Panel-Making Machine Production Line Manufacturing OEM Customized PVC Ceiling Production Line

>> D. Koln Tiger King 6.8% Vol Alcohol Content German Craftsmanship Beer 330mltraditional Brewing Canned Strong Lager Canned Mature Beer OEM/ODM

>> Customized Shell Color PA Type 12m-20m Lifting Height Mini Electric Hoist for Construction Building Manufacture

>> New 2.5m Four Hydraulic Cylinders for Farm Use Manufactured by Grader Companies

>> L29 Din Connector 7/16 plug male Cable Connector For Feeder 1/2''Flexible circular

>> 8mm 0.4-0.65 Density China Manufacture Hot Sale PVC Foam Sheet

>> OEM tri Wheel Sugarcane Grab Loader which anti-quake, anti-loose, stand fire

>> Feed Pellet Production Line Making Feed Pellets

>> Yamamoto Motorcycle Accessories Rear Hydraulic/Rubber/Gas/Spring-Air Shock Absorber for Honda Forza250

>> Manufacturers Pure X Ray Protection Shielding Medical Lead Sheet in Coils

>> Speed Two-Axis Shredder Bladecustomization PVC Plastic Shredder Machine Blade

>> Double Direction Cutter for Granite Block Use by Joborn Stone Machinery

>> Single Door/Double Door Display Showcase Refrigerator OEM Electronic Temperature Display and Compressor Back Cover

>> Melamine Veneer Wood Door Hydraulic Hot Press Machine