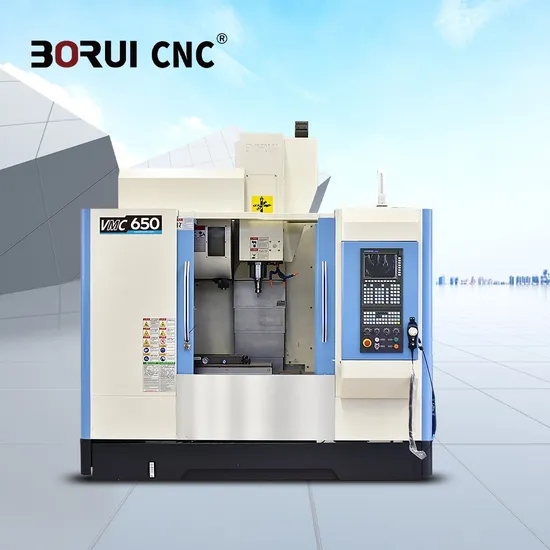

Vmc650 Small Vertical Machining Center CNC Milling Machine for Sale

Basic Info.

Model NO.

VMC650

Movement Method

Point to Point Control

Control Method

Semi-Closed Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Model No.

Vmc650

Machine Type

Vertical Machine Centers

Controlling Mode

CNC

Max.Spindle Speed

8000 R/Min

Table Size

800X400

Tool Changer Type

Disc Type

Product Name

3-Axis Vertical CNC Machining Center

Processing

Maching Center

Control System

Siemens GSK Fanuc (Optional)

Spindle Taper

Bt40

Max. Tool Length

250/350 mm

Transport Package

Free Fumigation Plywood Packaging Steel Base

Specification

2300*2200*2400mm

Trademark

BORUI

Origin

Shan Dong

HS Code

8457101000

Production Capacity

500

Packaging & Delivery

Package Size

200.00cm * 230.00cm * 240.00cm

Package Gross Weight

4000.000kg

Product Description

Vmc650 Small Vertical Machining Center CNC Milling Machine for SaleProduct Description

The VMC650 vertical machining center consists of main engine, CNC system, electrical control system, automatic lubricating system, cooling system, totally enclosed protective cover, automatic chip removal device (optional) etc.The machine has the X, Y, Z three axis linkage, in a clamping can finish milling, drilling, boring, expanding continuously, hinge, such as the internal and external screw thread processing a variety of rough and finish machining process, is suitable for processing all kinds of high precision, working procedure, shape more complex parts, to provide users with complex parts processing and quick, perfect integration solutions.

The machining center/milling of feed shaft for X, Y, Z three coordinate control, three axis through the servo motor drive, can achieve for a variety of plate, plate and shell, a complex parts, such as CAM, mold clamping, complete drilling, milling, boring, expansion, reaming, tapping and other process, are suitable for many varieties, small batch parts production, for complex, high precision parts processing and more shows its superiority.

Product Parameters

The main specification :

| Specifications | Units | VMC650 |

| Table size | mm | 800x400 |

| X axis travel | mm | 650 |

| Y axis travel | mm | 400 |

| Z axis travel | mm | 500 |

| Max. worktable load | kg | 400 |

| T slot(number-width-pitch) | mm | 3*18*125 |

| Max. spindle speed | rpm | 8000 |

| Spindle taper | mm | BT40 |

| Main motor power | kw | 5.5 |

| X/Y/Z rapid traverse speed | m/min | 24/24/20 |

| Cutting feed speed | mm/min | 1-10000 |

| Guide rail type | | Linear rail |

| Distance from spindle axis to column surface | mm | 550 |

| Distance between spindle nose and worktable surface | mm | 120-620 |

| Positioning accuracy | mm | ±0.008 |

| Repeat positioning accuracy | mm | ±0.005 |

| Tool magazine | | 16 |

| Machine weight | kg | 4000 |

| Overall dimension | mm | 2400X2000X2550 |

Standard accessory Optional accessory1.Fanuc-0i-mate-MD 1.Mitsubishi M70/GSK218M/Fanuc

2.full enclosure machine guard change 2. Funnel type tool change

3.Arm type ATC 3.chip car

4.automatic central lubrication system with alarm 4.4th axis

5.Z axis counter-balance weight 5.Metrol tool setters

6.spindle cooling unit 6.transformer to suit local power supply

7.spindle side air blow 7.screw type chip conveyor

nozzle&coolant nozzle

8.machine window with safety glasses

9.rigid tapping

10.auto power off

11.3 colours warning lamp

12.work lamp

13.leveling pads&bolts

14.operation manuals

15.tool holder and pull stud

Details Display

The main feature : 1. Adopting the world advanced numerical control system, the M60S series are servo-driven, ensuring the stability of the control system is high, the speed is fast, and the surface is smooth.

The advantages of high precision, the ability to make moulds, is the best choice for mold production.

2. All M60S series controllers are marked with RISC64 bit CPU.

3. Coordinate display value conversion can be freely switched (program value display or manual insertion quantity display switching)

4. Standard internal carrier profile function, working position coordinates and central point measurement functions.

5. Buffer correction function extension: can correspond to IC card/computer link B/DNC/MDI mode.

6. Edit the edit mode in the edit screen, and switch to edit or edit the whole page.7. Graphical display function improvement: can contain the prop path information to fully display the work coordinates and the actual location of the props compensation.

Packaging & Shipping

Packing shipping

For machine: usually by sea; For documents: by international express, eg. DHL,TNT or EMS. For packing :Free fumigation plywood packaging steel base our service 1. Technical support online service provided. 2. Technical files service provided. 3. Machine operation video provided 4. On-site training service provided. 5.Spare parts replacement and repair service provided. 6 All of the questions will be replied within 8 hours 7. If you need to develop products with your own specification, we can help you to work it out. 8. Always be honest, never lie to customer, and never declare anything we don't have Company Profile

Since 1996,20 years' history for machine tool manufacturing

10 years' history for export

Total 2 manufacturing bases in china

Sino-germany technology cooperation

Production of 8 categories, more than 130 kinds of products

Set up design&research center at TAIWAN

Exported to total 48 countries in the world covered most areas

One-stop shopping for nearly all other types' machine tools

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on .

3: Where is our factory located? How can I visit there?

A : Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;

Irrevocable LC at sight .

5: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

We want to know:

1.What's your Industrial Voltage?

2.We strongly suggest you to tell us size, material of your workpiece for our evaluation, if possible, better to send us workpiece drawing, so that we can recommend you most suitable model!

3.If need CIF Price, please kindly tell us the port of destination.

>> 7KG Factory Custom Portable Semi Automatic Portable Twin Tub Washing Machine

>> Modern Natural Pink Crystal Ball Craft Products Office Ornaments Home Interior Decoration

>> New Type 1000W 1500W 2000W Portable 3 In1 CNC Fiber Laser Cutting Machine, Max Laser Is Used

>> High Precision 3 Axis Vertical CNC Milling Machine for Efficient Production

>> ZX6350CW Fresadora Taladro Vertical Universal Milling Drilling Cutting machine

>> 1325/1530/2030/2040 4 Axis Atc Rotary Woodworking CNC Machine Center Wood Design Machine for Plywood/MDF/Foam/Pep/PP/EVA Cutting Engraving Milling

>> China Factory Disposable Waterproof Coverall Industrial Full Body Overall Suit Chemical Resistant Coverall Jumpsuit

>> Automatic Hydraulic Uncoiler/Decoiler for Cold Roll Forming Machine with ISO9001/CE/SGS/Soncap

>> HP Graphite Electrode 350mm

>> peanut butter manufacturing process | Peanut Butter Making Machine

>> PS15 Audio Sound, Audio Sound Equipment

>> 2024 Factory Cheap Price Reno10 PRO+ 7.3inch Smart Phone Mobile Phones

>> Factory Supply High Quality Custom Die Casting Metal Hard Soft Enamel Lapel Pin Shield Shaped Plated Blank Pakistan Forces Security Military Police Pin Badges

>> Pure 100% Cashmere Sweater Knitting Women Pullover Full Cardigan Stitch Unique Design of Shoulder Sleeve Self-Knitted Neck Luxurious Knitwear

>> Factory Price Automatic 1L 5L Cooking Oil Bottle Filling Machine Vegetable Oil Filling Machine Sunflower Oil Filling Machine

>> Best Price Side Mirror Glass Cover for Toyota CAMRY ASV50 AVV50 ASV51 2015 87961-06490 L

>> Villa Aluminum Window Casement Window Swing Window

>> Low Failure Rate Best Price 6m Lifting Height Mini Electric Scissor Lift for Sale

>> Flexible PCB Board PCBA Assmebly

>> White 120ml Ceramic Aromatherapy Machine Essential Oil Diffuser Household Humidifier

>> Custom 3D Make Logo Cufflink Metal Cuff Buttons Pins Shirt Cufflinks

>> Taijia digital water stainless steel flowmeters Ultrasonic Doppler portable flowmeter flow meter

>> Factory Direct Sale Two Roll Rubber Mixing Mill Open Rubber Mixing machine (4/6/9inch)

>> Intelligent Plastic Cup Thermoforming Machine (HFTF-70T-H)

>> White Paper Cover Bottom Cardboard Paper Gift Packaging Boxes with Ribbon Bow

>> 200L Perfume Mixing Machine Perfume Production Mixer Tank with Filter

>> High Speed 18 Inch Industrial Pedestal Stand Fan with Large Air Volume

>> Double Glazed Round Window Glass Circular Aluminum Round Windows

>> Galvanized Automatic 4 Tiers Battery Meat Chicken Feeding Cage for Poultry Farm/ Farming Meat Broiler Raising Equipment

>> 100L/120L/240L/360L/660L/1100L Customizable Large HDPE Heavy Duty Outdoor Foot Pedal Wheelie/Waste/Garbage Bin/Storage Plastic Dustbin with Wheels