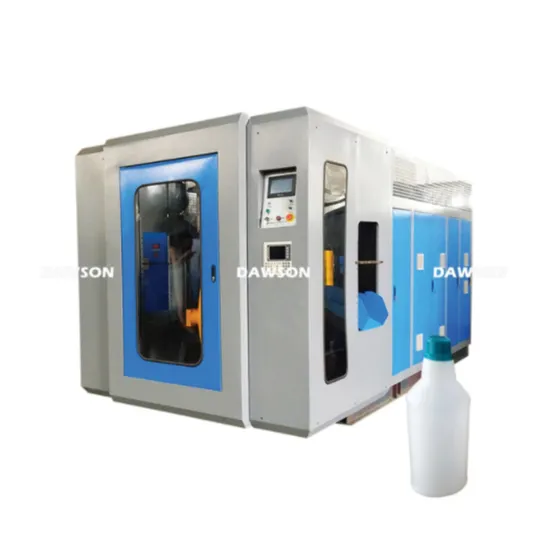

4L 5L Double Station Plastic Bottle Lubricant Oil Bottles Round Bottles Extrusion Blow Molding Machine

| US$36,800.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

TCY70II

Making Method of Parison

Extrusion-Blow Molding

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008

Application

Bottles, Jars, Jerry Cans, Gallons, Containers

Station

Single Station or Double Station

Die Head

Single Head or Double Head

Max. Product Volume

5L

Auto-Deflashing

with Auto-Deflashing

Clamping Force

68 Kn

Mould

One Cavity or Two Cavity

Suitable Material

HDPE,PP,PVC,PS,PETG,LDPE

Sutiable

0~5L Bottle

Made in

China

Platen Opening Stroke

200-500mm

Platen Size

360*470mm

Max Mould Size (W*H)

390*470mm

Mould Thickness

210-300mm

Platen Moving Distance

440mm

Transport Package

Film Packing

Specification

TCY70II-1

Trademark

DAWSON

Origin

Jiangsu Zhangjiagang

HS Code

8477301000

Production Capacity

180~200 PCS/H

Packaging & Delivery

Package Size

4200.00cm * 2200.00cm * 2700.00cm

Package Gross Weight

6000.000kg

Product Description

Product Description

DAWSON MACHINERY & MOULD GROUP

Extrusion Blow Molding MachineTCY75II SERIERS

suitable for making plastic bottle, jars, small containers, jerrycans from 50ml to 5L,

The whole blow molding machine is equipped with bilingual operation panel

and automatic configuration from world famous brands to realize the advantages of simple operation

and high automation.

| SPECIFICATIONS | UNITS | TCY75II SERIERS | |||

| Max container capacity | L | 5 | |||

| Number of die heads | Set | 1 | |||

| Dry cycle time | Second | 5 | |||

| Machine dimension (L*W*H) | M | 3.3*2.3*2.6 | |||

| Total weight | Ton | 5.5 | |||

| CLAMPING UNIT | |||||

| Clamping force | KN | 68 | |||

| Platen opening stroke | mm | 200-500 | |||

| Platen size | mm | 360*470 | |||

| Max mould size (W*H) | mm | 390*470 | |||

| Mould thickness | mm | 210-300 | |||

| Platen moving distance | Mm | 440 | |||

| POWER | |||||

| Extrusion motor power | KW | 22 | |||

| Oil pump motor power | KW | 5.5 | |||

| Extrusion heating power | KW | 12 | |||

| Head heating power | KW | 5.7 | |||

| Cooling Fan power | KW | 0.26 | |||

| Total power | KW | 45.46 | |||

| Average power consumption | KW | 23.5 | |||

| EXTRDER UNIT | |||||

| Screw diameter | mm | 75 | |||

| Screw L/D ratio | L/D | 24 | |||

| Plasticizing capacity | Kg/hour | 90 | |||

| Number of heating zone | Zone | 3 | |||

| Extruder heating power | KW | 14.2 | |||

| Extruder driving power | KW | 22 | |||

| Cooling Fan No | 2 | ||||

| Fan power | KW | 0.26 | |||

| DIE HEAD | |||||

| Head type | Continuous extrusion head | ||||

| Head No | 1 | 2 | 3 | 4 | |

| Central distance / mm | - | 160 | 110 | 85 | |

| Max die diameter / mm | 135 | 80 | 50 | 30 | |

Photos Reference

Finished Product

Detail Images

High Quality Blow Molding mould

In the process of plastic blow molding, the mold is a very important part. A good blow mould can make the product production more smoothly, and a good blowing mold can also make the finished product more flexible and beautiful.

We have our own mold production workshop, using high configuration equipment and mold engineers with 16 years of technical experience to customize blow molding mold for you.

- We use the best stainless steel S136H or Aluminium alloy 7075# as mould main material- Necking plate use JAPAN DC53 Heat

treatment to HRC62

- Double neck design available to change in future as a spare part necking

- All mould can be made auto-deflashing or manual deflashing as per customer requests

- Perfect mould cooling design to ensure the best moulding preformace

- Available to provide 2D & 3D product drawing for customers

- Available to send samples to customer for approval the product quality

- We had already made moulds for TOTAL,SHELL,GULF,BMW,YAMAHA,MOBIL,TOYOTA,MENGNIU, HYUNDAI,MENTHOLATUM,UNILEVER,LEE KUM KEE...

Company Profile

DAWSON MACHINERY & MOULD GROUP

Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India, Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria, South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia, Venezuela, Peru....

We have our own service team in

Saudi Arabia, Colombia, Panama, South Africa ...

DAWSON MACHINE & MOULD GROUP

located in Zhangjiagang city, have more than 18 years' experience in the field of plastic machinery,

blow molding machine, injection molding machine, PET blow molding machine, injection blow molding machine, during the past 18 years, we always force our energy into new areas of plastic machinery, plastic packaging machinery, to update the technology, to learn advanced experience,

to confirm new theory and new design, we are forming a unique competitive advantage of our owns.

The machines from our company carry good quality and effective after-sales service, upon the market,

customers from more than 45 countries, we provide complete solution for your plastic industry

business, as well as all sorts of technical support & after-sale services!

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!

FAQ

Q: Can we visit your factory?Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai PudongInternational Airport. We canpick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.Q: How can we get the exact price of plastic machine?Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models withquotation.Q: Do you provide any spare parts with machine?Yes, we offer all necessary spare parts before shipment.(contact us for packing list )Q: How about your after-sale service ?We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technicalsupport or field installation assist.Q: What is the lead time?For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)Q: What is the warranty period for your machine ?12 months warranty for components and technical support .Q: Do you provide custom machines?Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customersproducts to meet customer' needs.Q: How can we install the machine when it arrives?We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train thecustomer's employees.Q: What's DAWSON's advantage?DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also wecan source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will savea lot of cost and time.DAWSON will be your reliable friend in China, and we will always do our best to give you max support!

>> 24 Inch Open Type Two Roll Rubber Mixing Mill Xk-610

>> Dental Instrument Dental Unit, China Foshan Dental Chair with Good Price

>> Portable Digital Non-destructive Ultrasonic Detector Of Concrete cheap price

>> Top Quality Chinese Yellow Fresh Onion Whole Onion Size 50/60/70/80

>> Feed Processing Machines Animal Feed Pellet/ Animal Feed Pellet Making Machine/ Pelletizer for Animal Feed

>> CE Certified CNC Machining Center for T Series High Speed Drilling Lathe

>> Large Scale Horizontal Bead Mill Price

>> Silage Agricultural and Fodder Chaff Cutter Machine for Dairy Farm Hay Straw Forage Chopper Animal Feed Milling Crushing Machine

>> Plastic Standard Size Document Clipboards

>> OEM/ODM Handheld 2000W Wobble Fiber Laser Manual Marking Cutting Welding Head Gun for Laser Welder Machine Air-Cooled

>> Z5140 Z5150 Square Pillar Column Upright Vertical Drilling Machine

>> 3D Embossed Wood Grain Outdoor Waterproof WPC Flooring Composite Plastic-Wood-Fencing

>> 20mn Material Black Anchor Chan for Ship

>> Stainless Steel 304 UL CE Security Fire Rated Door Furniture Accessories Building Door Hardware Commercial Fitting Door Lock Hinge Wood Door Hardware

>> Coupling for Transmission Con. Ecc. Reducer Tee Bend Elbow Cap Butt Weld Pipe Fitting Pipe Fitting Carbon Steel/ Stainless Steel/Alloy China Products/Supplier

>> China Automatic Feeding Strong Bench Drilling Machine (Z4132G)

>> Clear BOPS Plastic Slice Cake Bread Box Thermoform Cupcake Boxes with Clear Anti-Fog Lid

>> Honey processing line bee honey extractor machine honey purify machine

>> Efficient Automatic Taiwanesewasher Assembly Machine for Fastener Production Line

>> Wholesale High Pressure Non Asbestos Yarn Pump Gland Packing Packing With Ptfe

>> High Quality Imported Parts Round Knife Grinding Machine

>> 140CRA93200 CPU module

>> Wc67y/K-125t2500 Hydraulic Press Brake/Sheet Bending Machine

>> Maictop car accessories New Facelift M Sport Moder bumper body kits For Land Cruiser 300 LC300 2022 Bodykit

>> RELIANCE S-D4006-D S-D4006 brand new in stock

>> High Quality Small Plastic Injection Machine

>> 2019 fcctory rice 1.5T 2.0T car engine skid plate for BMW X1 2series

>> Good Quality Plastic PE 12 Pole Terminal Block Electrical Terminal Strip

>> New Arrival Fast Charging QC3.0 Quick Charger 3 USB Car Charger Adaptor car phone charger

>> Small CE High Quality High Performance Mini Crawler Hydraulic Excavator Bucket Wheel 0.5 Ton 0.8 Ton