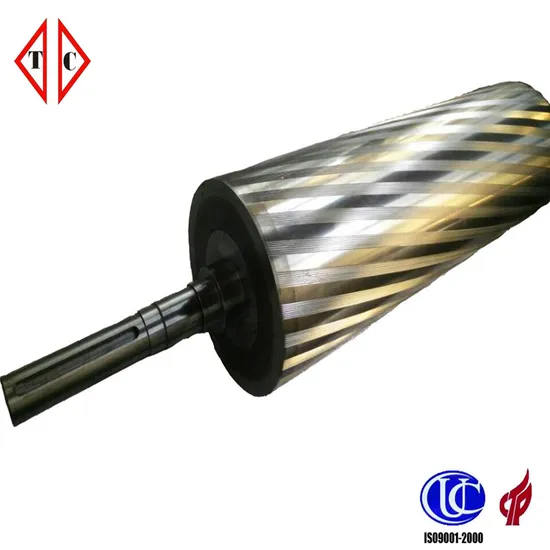

Experienced Supplier Mill Roll for Cotton Seeds Crusher Machine Spare Parts

| US$1,000.00 | 2 Pieces (MOQ) |

Basic Info.

Application

Soybean, Peanut, Pumpkin Seed, Sunflower Seed, Corn, Walnut

Product Name

Cracking Roll/Crushing Mill Roll

Roll Diameter

100-600mm

Body Length

500-1800mm

Alloy Thickness

25-30 mm

Roll Hardness

HS75

Material

High Nickel-Chromium- Molybdenum Alloy Outside, Qu

Casting Method

Centrifugal Composite Casting

Casting Technology

German Centrifugal Composite

Roll Finish

Nice Clean and Fluted

Package

Wooden Case

Weight

300-3000kg

Transport Package

Wooden Case

Specification

required by customer

Trademark

TCROLL

Origin

China

HS Code

84379000

Production Capacity

100000PCS

Product Description

Oil seeds Cracking Mill Roller

Cracking rollers are the main components in oil seeds cracking mills. Oil seed cracking rollers are used to crack or crush oilseeds like soybeans, sunflower seeds, cotton seeds, etc. Oil seed cracking rollers are a key component in the oil seed processing industry.

The rollers consist of two corrugated or ribbed cylinders rotating in opposite directions with a very small clearance between them. The clearance, known as the cracking gap, is usually between 0.25-0.35 mm. As the oilseeds pass through this gap, they are cracked into smaller pieces and flattened.

Cracking the oilseeds achieves several purposes. It ruptures the cell structure of the seed to release the oil and improves the efficiency of extracting the oil. It also increases the surface area of the crushed seed for better oil release. The cracking rollers break the seed into uniform sized cracked pieces for efficient downstream separation of hulls and meats.

The rollers are typically made of cast iron and range from 12-54 inches long and 5-20 inches in diameter. They are mounted on bearings and driven by motors and gear systems at different speeds. Proper roller gap adjustment, seed feed rate, and roller corrugation pattern are necessary for optimal cracking. The rollers require routine maintenance and lubrication for smooth operation.

Advantages:

With over 30 years of history the cracking roller is the core product of our company.

Wear resistant: made of high quality nickel-chromium-molybdenum alloy by compound centrifugal casting to ensure durability under high pressure.

Low dust generation and high safety: Rollers produce less dust compared to impact or roll mill cracking methods. Less risk of dust explosions.

Energy efficiency: Corrugated surface to improve grip and feeding The continuous crushing action of the rollers requires less energy than impact crushing. Suitable for various oil seeds like soybeans, peanuts, cotton seeds, etc.

Simple maintenance: Rollers have relatively simple maintenance without complex parts prone to wear and failure.

Increased oil yield: Cracking the seeds ruptures the oil cells and exposes more surface area for extraction, improving oil recovery.

Competitive price: Adopted German casting technology, manufactured in China.

| A | Product Name | Cracking roll/Crushing mill roll |

| B | Roll Diameter | 100-500mm |

| C | Body Length | 500-3000mm |

| D | Alloy Thickness | 25-30 mm |

| E | Roll Hardness | HS75±3 |

| F | Material | high nickel-chromium- molybdenum alloy outside, quality gray cast iron inside |

| G | Casting Method | Centrifugal composite casting |

| H | Assembly | Patent cold packaging technology |

| I | Casting Technology | German centrifugal composite |

| J | Roll Finish | Nice clean and fluted |

| K | Roll Drawing | ∮400×2030,∮300×2100,∮404×1006,∮304×1256 Or Manufactured per drawing provided by client. |

| L | Package | Wooden case |

| M | Weight | 300-3000kg |

FAQ Q1. Are You a Trading Company or Manufacture ? A1: We are a factory , which has been established for 30 years. Strict quality control of production processes and tolerances.Manufacture products according to your drawings or specifications. Q2: How to choose the products that meet our requirements?

A2: Tell me the information of the product, or provide us drawings.

Q3:What is the quality of your products?

A3:Quality is always the foundation of our company, I suggest you buy samples to evaluate the quality

Q4: How long does the delivery period take?

A4: Generally speaking, Delivery time takes 20-45 days, but we are very flexible depending on the specific order.

Q5: Can you do OEM / ODM orders?

A5: Yes,we have rich experience on OEM/ODM order and like sign Non-disclosure Agreement before sample making

>> 24 Inch Open Type Two Roll Rubber Mixing Mill Xk-610

>> Dental Instrument Dental Unit, China Foshan Dental Chair with Good Price

>> Portable Digital Non-destructive Ultrasonic Detector Of Concrete cheap price

>> Top Quality Chinese Yellow Fresh Onion Whole Onion Size 50/60/70/80

>> Feed Processing Machines Animal Feed Pellet/ Animal Feed Pellet Making Machine/ Pelletizer for Animal Feed

>> CE Certified CNC Machining Center for T Series High Speed Drilling Lathe

>> Large Scale Horizontal Bead Mill Price

>> Silage Agricultural and Fodder Chaff Cutter Machine for Dairy Farm Hay Straw Forage Chopper Animal Feed Milling Crushing Machine

>> Plastic Standard Size Document Clipboards

>> OEM/ODM Handheld 2000W Wobble Fiber Laser Manual Marking Cutting Welding Head Gun for Laser Welder Machine Air-Cooled

>> Ranbem Fast Boil Electric Water Kettles Cordless Home Heating Boilers Safe Plastic Smart Small Size Kettle

>> Flexo 1.70mm Black Color Digital Photopolymer Printing Plate Polymer

>> PFTL101B 2.0KN

>> Bricks Making Machine South Africa Hollow Blocks Business in Philippines

>> Used Second Hand Volvo Ec210 Ec210blc Ec210d Ec240 Ec250 Ec60 Ec140 Ec290 Ec360 Ec480 Engineering Machine Hydraulic Crawler Excavator Track Digger EPA CE New

>> Z5140 Z5150 Square Pillar Column Upright Vertical Drilling Machine

>> 3D Embossed Wood Grain Outdoor Waterproof WPC Flooring Composite Plastic-Wood-Fencing

>> 20mn Material Black Anchor Chan for Ship

>> Stainless Steel 304 UL CE Security Fire Rated Door Furniture Accessories Building Door Hardware Commercial Fitting Door Lock Hinge Wood Door Hardware

>> Coupling for Transmission Con. Ecc. Reducer Tee Bend Elbow Cap Butt Weld Pipe Fitting Pipe Fitting Carbon Steel/ Stainless Steel/Alloy China Products/Supplier

>> China Automatic Feeding Strong Bench Drilling Machine (Z4132G)

>> Clear BOPS Plastic Slice Cake Bread Box Thermoform Cupcake Boxes with Clear Anti-Fog Lid

>> Honey processing line bee honey extractor machine honey purify machine

>> Efficient Automatic Taiwanesewasher Assembly Machine for Fastener Production Line

>> Wholesale High Pressure Non Asbestos Yarn Pump Gland Packing Packing With Ptfe

>> High Quality Imported Parts Round Knife Grinding Machine

>> 140CRA93200 CPU module

>> Wc67y/K-125t2500 Hydraulic Press Brake/Sheet Bending Machine

>> Maictop car accessories New Facelift M Sport Moder bumper body kits For Land Cruiser 300 LC300 2022 Bodykit

>> RELIANCE S-D4006-D S-D4006 brand new in stock