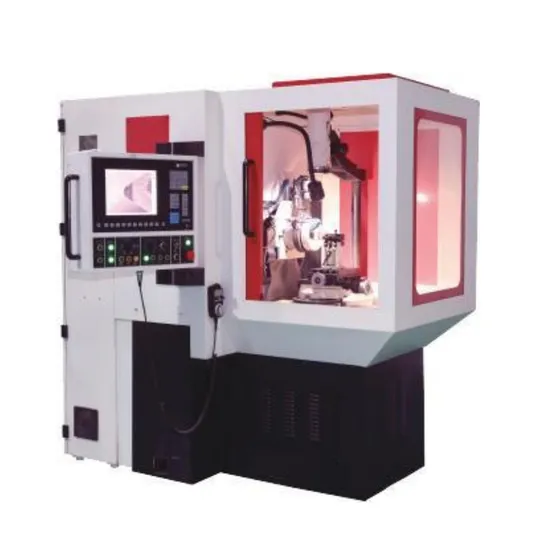

4-Axis CNC Tool Grinder Grinding Machine for PCD Inserts

| US$69,800.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

BT-150D

Type

Tool Grinding Machine

Processing Object

Curve

Abrasives

Grinding Wheel

Controlling Mode

CNC

Automatic Grade

Automatic

Cylindrical Grinder Type

Universal Cylindrical Grinder

Precision

High Precision

Certification

ISO 9001

Condition

New

Free Trial Grinding

Yes

Weight

2400kg

Diameter of Grinding Wheel

150mm

Voltage Requested

380V/Three Phase /50Hz

Transport Package

Wooden Case

Specification

1890mm*1650mm*1980mm

Trademark

DEMINA

Origin

China

HS Code

8460390000

Production Capacity

50 Sets Peryear

Product Description

Product Description

BT-150D is made of grinding wheel oscillation axis(X-axis), grinding wheel tilt angle axis (B-axis), rotation axis in the horizontal plane(C-axis), working piece feeding axis(Y-axis). working piece feeding axis(Y-axis) is equipped with raster rule, and the closed loop position feedback is used to ensure the precision of micron level grinding.

The tool grinder is reliable in performance and it is suitable for massive production of carbide inserts, PCD and CBN inserts. Once centering is finished, grinding will be done automatically, realizing constant pressure grinding and flexible feed. The even consumption of grinding wheel can be measured and compensated by the system, so production with long cycle time can be achieved. Scope of use of BT-150D

Product Parameters

| 1 | Diameter of Grinding wheel | 150mm |

| 2 | Grinding wheel center hole | 40mm |

| 3 | Power of grinding spindle | 5KW |

| 4 | Adjustable range of grinding speed(RPM) | 5000~8000RPM |

| 5 | Servo motor swing frequency | 0~50times/min |

| 6 | Grinding wheel movement range(X ) | 350mm |

| 7 | Changeable Clearance Angle | -5°~25° |

| 8 | Table movement range in feed direction(Y) | 130mm |

| 9 | Work-piece rotation range in axial direction | 360° |

| 10 | Linear scale resolution | 0.001mm |

| 11 | Encoder resolution | 1' |

| 12 | Max Magnification of Optical Microscope | 0.7~4 times |

| 13 | Magnification of CCD Measuring System | 80times |

| 14 | Coolant Tank with Filter Paper | About 70 L |

| 15 | Overall Dimensions L*W*H | 1890*1650*1980mm |

| 16 | Weight With Coolant Tank | 2400KG |

| 17 | Electrical Supply | 12Kw |

| 18 | Voltage Requested | 380V/Three phase /50Hz |

Detailed Photos

Packaging & Shipping

After Sales Service

1. The warranty period of the whole machine is one year for life.

2. During the warranty period, all kinds of failures are repaired and free of charge in time, and all kinds of non-man-made damage to parts will be replaced free of charge in time.

3. Outside the warranty period, the supplier provides lifelong paid maintenance services. If the parts are replaced, the supplier supplies the demand side at a cost price.

Company Profile

Demina mainly engages in mass production of CNC tool grinding machine and provides tool regrinding service. We have been in the field over 20 years. It is a national high-tech enterprise and a SRDI enterprise in Beijing.

Our company's independently developed BT-150 series PCD tool grinding machine closely combines traditional tool grinding technology with software technology. On the basis of ensuring the accuracy of tool grinding, we have achieved CNC tool grinding technology, greatly improving the work efficiency of tool enterprises and effectively reducing their operating costs. According to the different technical requirements of our customers, our BT-150 series PCD tool grinding machine have three types: manual action, manual and automatic integration, and CNC operation. Among them, the CNC tool grinder with specially developed software is in a leading position in the industry in China. In addition to providing high-quality products, we also provide customers with comprehensive and high-quality after-sales technical support.

>> Factory Price Engine Parts Timing Camshaft Gear Assy Cvvt Intake Assembly 243702G000 24370 2G000 24370-2G000 For Hyundai

>> Amazon Hot Sale 2022 Custom Food Grade Long Handle Nonstick Spatula

>> SHENGKE Customize Lady Watch Japan Quartz Movement Watches Wholesale Mesh Band Watch

>> DAIWA hot sale high quality fishing spinning reel saltwater fishing reel for sale

>> Spider Sinker Claw Shaped Breakway Sinker Fishing Lead Weight Fishing Tackle

>> Automatic laundry detergent bottle sticker machine maker electrical machinery price

>> Manual sugar cane juicer, sugarcane juice making machine, sugarcane juice extractor

>> Diamond Saw Blade Welding Strength Testing Machine for Diamond Saw Blade

>> Mt Medical Portable Medical Examination Lamp LED Mobile Surgical Light

>> Electric Mini Kitchen 3 in 1 Sandwich Waffle Maker Breakfast Grill Donut Cake Maker Machine

>> 4mm 20m Plastic Nylon Cable Puller Wire Fish Tape Electrical Wire Puller

>> High Quality OEM Ductile Iron Lost Wax Precision Casting CNC Machining Price

>> 6 Inch Two Roll Open Mill for Rubber and Plastic Mixing Laboratory

>> Bright Golden Rich Gold Color Bronze Powder Pigment for Indoor Decorative Paint

>> 1.5-45mm Diameter Tungsten and Solid Carbide Rods of Serials Xn06 for Cutting Tools

>> Hot Sales 2020 Summer Hole Skinny Sexy Jeans

>> Wholesale Price Pharmaceutical Equipment Automatic Hard Gelatin Capsule Filling Production Line Electric Rotary Capsule Filling Manufacturing Machine

>> 2021 New Style 175rpm Cable One Scrubber Floor Cleaning Machine Including All The Spare Parts

>> Easy to Operate Full-Auto PP Intermittent Gluing Production Line Plpp-700c

>> High School Scale Architectural Model Maker Custom Building Apartment 3D Physical Model

>> Cute Charging Treasure Cartoon Pattern Compact Mini Powerbank Mobile Power Supply

>> MMCX to MMCX with RG316 Cable, Adapter Cable Right Angled MMCX Male Cable

>> R160 Multi Jet Dry Type Water Meter with AMR (NX-1)

>> CNC Stone cutting machine for marble and granite

>> Cold Saw Blade Sharpener Long Service Life High Precision

>> Custom Fin Aluminum Heat Sink for Solar Panel

>> 1380 mm Size Light Trap/ Poultry Farm Light Trap, Greenhouse Light Trap

>> 1uz 2uz Crankshaft for Toyota Ls 400 V8 4.0 Sc 400 Land Cruiser Gasoline Engine Parts OEM1341150040

>> Foryou Medical PVA Nasal Dressing Sponge Material Stop Bleeding

>> Shineray Car Swm Go1 Car Door and Window Regulator Assembly Glass Regulatorglassshakerelectric Regulator Electric Switch