Popsicle Ice Cream Sticks Lolly Making Machine with Heating Function

Basic Info.

Model NO.

XI-4

Process

Thermal Processing

Automatic Grade

Manual

Application

Ice Cream

Compressor

Tecumseh

Refrigerant

R404A

Cooling Style

Air Cooling or Water Cooling

Temperature

-28 to -35 Degree

Material

304 Stainless Steel

Mould

2 to 12 Moulds

Power

1200W

Voltage

Can Be Chosen

Size

Can Be Chosen

Transport Package

Wooden Case for Export (Packed in Three Veneer)

Specification

CE Approved

Trademark

XSFLG

Origin

Guangdong, China

Production Capacity

200PCS/Month

Product Description

Normal style Parameter:| Model | Voltage | Power | Power of Heating Zoom | AMPS | Refrigerant | Cooling way | Mold /Set | Production /pcs/day | Dimension /mm | N.W. /KG |

| XI-2 | 110/220V60Hz, | 1.5kw | R404a | Air | 2 | 8000 | 1000x650x1185mm | 130 | ||

| 220V/50HZ | 2KW Max | 17.5AMPS | ||||||||

| XI-4 | 110/220V60Hz, | 2.3kw Air-Cool 2.9KW Water-Coo | Air-Cooling 17.5 Water-Cooling 24.5 | R404a | Air or water | 4 | 16000 | 1450x650x1185mm | 155 | |

| 220V/50HZ | 2KW Max | |||||||||

| XI-6 | 110/220V/380V | 3.0kw | 2KW Max | R404a | Air or water | 6 | 24000 | 1950x650x1185mm | 220 | |

| 60/50HZ | Air-Cooling -25 | |||||||||

| 60/50HZ | ||||||||||

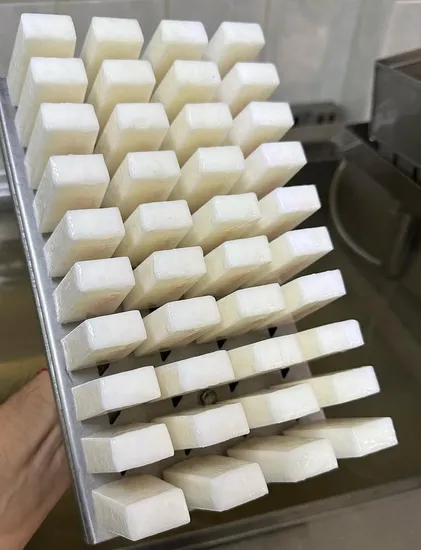

This is a machine for producing water-based or milk-based popsicles.

2 Moulds machine / thermostat controls water temperature of mold release.

It is a very fast machine, proved by many successful businesses.

Produces about 200 popsicles/hour, with 2 moulds of 40 sticks for each --- perfect machine for small shop

*Production depends on the climatic conditions of the location where the machine is installed.

Compact, durable. Rotary/lock wheels make it easy to move and transport.

Body structures are made from stainless steel 304.

Powerful, practical, and silent: French Tecumseh compressor inside our machine and well tested Low

One Phase 220V, 50/60 Hz; Air-cooling system

How to make yummy, healthy, and great for picnics, fresh juicy ice lollies? It will cool down on a hot summer's day. With XSFLG's new design popsicle machine, it only takes a few minutes to put together, and can satisfy anyone's sweet tooth. Why not try to add it to your business?

Step 1:

Turn on the machine till the temperature arrives -25 degrees

Pour the mixture(milk base / water base / juice base) into your ice lolly moulds.

Don't fill them all the way to the top, as the liquid will expand as it freezes.

Step 2

Take the lolly out of the mould once frozen. The time this will take depends on the size of your lollies,

But as a guide, they should be frozen after about 20-25 mins.

Step 3

Put the moulds into the hot water ( Heating Zoom) and count 1,2,3,4,5; then release them from the mold.

Tips

You could also put some pieces of fruit in your mixture.

Try a different juice/fruit to change the taste! Or maybe mix two juices together... The possibilities are limited only by your imagination.

You could try adding solid pieces of fruit - This will add a different texture and flavor.

Our Ice Lolly machine is working well in Europe / USA / Canada and Africa Market.

If you're from the Middle East Market --- March 2023 we already had a 14 day after-services training visit from

Dammam to Riyadh , then Dubai. Soon around Aug. 2023 we will visit Dubai & KSA again to test our machine & popsicle ice cream showcase, sticks ice cream cart again during the most hot season.

>> Professional Corrugated Cardboard Shredder Mesh Cardboard Shredder for Parcel Filling

>> Fashion Customized Promotion Stationery School Supplies Paper Stickers Index Sticky Note

>> DIY Framed Dried Flower Art Everlasting Flower Display Stand Christmas Gift Tools Plant Crafting for 3D Painting Material Kit

>> Hjc Reliable RO System Membrane for Household Water Filtration

>> Huayu 2000L 3layers Plastic Water Tank Extrusion Blow Molding Machine

>> Roller Shell for All Kinds of Pellet Mills

>> Tungsten Carbide Dies for Food Processing Machinery

>> Chicken Farm Broiler Poultryraising Equipment Automatic Pan Feeding System

>> Auto Feeding 1610 Fabric Laser Cutting Engarving Machine 80W 100W 130W for Footwear

>> Heavy Duty Galvanized Roof Warehouse Steel Storage Metal Arm Cantilever Rack

>> CNC Lathe Machine (LNC6132C)

>> Reliable Digital Flexo Plate Machine, Weighing 2800 Kg for Optimal Performance

>> Hot Sale Fashionable Innovation Factory Outlet Wholesale Advanced Great Quality Durable Power Tiller

>> Hydraulic Manual Steel Bar Cutter Heavy Metal 40mm Steel Cutting Machine

>> 3-Axis Vertical Machining Center High-Quality Metal Processing CNC Milling Machine

>> CE 52cc Post Hole Digger Drill Ice Manufacturing Plant

>> Free Sdk 13.56MHz RFID Card Reader NFC Reader Writer ACR122u

>> L230 Coating Thickness measurement

>> byloo Wholesale 2022 New Large Capacity 130cm 140cm 150cm 155cm Hard PVC Wearable Fishing Rod Bag Waterproof Case

>> Supply Jinding m2z-5 / 13 hydrogen diaphragm compressor

>> Frequency Automatic Women Sanitary Towel Machine

>> GF1500lb Good Quality Servo System Injection Molding Machine for Plastic Chair

>> Modern Hotel Style Rechargeable Table Lamp Metal Lampara De Mesa Portable Outdoor Cordless Electric Table Lamp

>> Sustainable Paper Box Featuring UV Coating and Two-Sided Printing

>> OEM Factory Fitness Wear Custom Sublimation Legging

>> Multifunction Professional Farm Electric Sheep Shears Goat Clippers Shearing Clipping Grooming Wool Farm Pet Supplies Livestock

>> Acrel Amc100-Fak48 Multi Channels AC Precision Power Distribution Monitoring Device for Data Center RS485

>> Taijia ultrasonic portable insertion flowmeter variable area water flowmeters

>> groundnut harvesting machine/peanut harvesting machine peanut harvester machine

>> German Technology Elm Hardwood Herringbone Wood Parquet Laminate Flooring