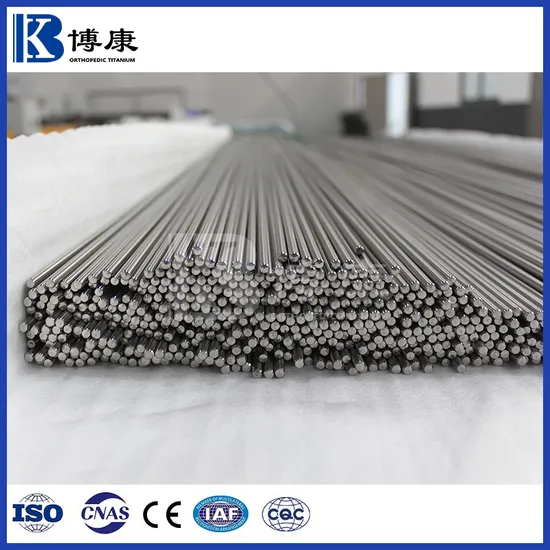

Medical Implant Titanium Round Rod Factory Manufacturer Ti-6al-4V Titanium Alloy Bar Price

| US$14.00-40.00 | 1 kg (MOQ) |

Basic Info.

Model NO.

BKTR-M

Technique

Hot Rolled

Grade

Gr1,Gr2,Gr3,Gr4,Gr5,Gr9,Gr23

Shape

Round

Material

Ta6V Titanium Alloy

Color

Silver

Surface Treatment

Polishing

Standard

ASTM, ISO, AMS, JIS, DIN

Tolerance

H6, H7, H8, H9

Condition

Annealed (M), Cold Rolled(Y), Hot Rolled(R)

Surface

Bright

Length

500-4000mm

MOQ

1kg

Sample

Available

ODM & OEM

Acceptable

Transport Package

Wooden Case

Specification

1.0~101.6mm

Trademark

Bokang

Origin

Changzhou, China

HS Code

8108901090

Production Capacity

200tons/Year

Product Description

Product Description High-Quality Titanium Rods - Pure & Alloy Options AvailableBokang Titanium specializes in pure titanium rods (Gr1, Gr2, Gr3, Gr4) and titanium alloy rods (Gr5, Gr9, Gr23, etc.), offering premium-grade materials for medical, aerospace, and industrial applications.

Medical Titanium Rods - Ideal for orthopedic implants, dental applications, and medical devices.

Aerospace Titanium Rods - Used in fasteners, profiles, and high-strength forgings.

Industrial Titanium Rods - Engineered for high-performance industrial needs.

With a complete in-house production process, including melting and customization, we ensure precision and reliability. Bokang is ISO 13485:2016, ISO 9001, and ISO/IEC 17025:2017 certified, and our titanium rods meet ASTM, ISO, AMS, ASM, JIS, DIN standards.

Contact us today for a quote or to discuss your specific requirements!

Titanium Bar Specifications

| Grade | Gr1,Gr2,Gr3,Gr4,Gr5(Ti-6Al-4V),Gr9(Ti-3Al-2.5V),Gr23(Ti-6Al-4V ELI), etc |

| Standard | ASTM F67;ASTM F136; ISO5832-2;ISO5832-3;AMS4928;AMS4965;AMS4967;ASTM B348; ASTM B863 |

| Diameter(mm) | 1.0~101.6mm |

| Length(mm) | 500-4000 |

| Tolerance | h6,h7,h8,h9 |

| Shape | Round |

| Condition | Annealed (M), Cold rolled(Y), Hot rolled(R) |

| Surface | Bright Surface |

Titanium Round Bar - Key Features

Superior Surface Finish - Smooth and precise for optimal application.

Excellent Roundness - Ensures uniform shape and consistency.

Tight Tolerances - High precision for demanding industries.

High Dimensional Stability - Reliable performance under various conditions.

Consistent Composition - Uniform material properties for enhanced durability.

Fine Grain Structure - Strength and toughness in every bar.

Exceptional Performance - Engineered for high-strength applications.

Extended Fatigue Life - Designed to withstand long-term stress and usage.

Precision, Performance, and Reliability - Choose Bokang Titanium!

Titanium Round Bar Production Process:

Sponge Titanium→Compacting Electrodes→Electrode Welding→Triple VAR Melting→Machining→Forging Billet→UT testing→Rolling Billet→Online Straightening→Centerless Lathe→UT testing→Rolling→Metallographic Inspection→Wire Drawing→Precision Straightening→Heat Treatment→Mechanical test→Microstructure test→Centerless Grinder→Eddy Current Test→Polishing→Visual and dimension inspection→Product Marking→Packaging→Delivery

Applications of Titanium Round Bar:

Titanium rods are extensively used in the medical industry, providing exceptional strength, biocompatibility, and corrosion resistance. Key applications include: Orthopedic Implants - Hip and knee replacements, bone fixation devices.

Dental Implants - Durable and biocompatible solutions for long-term use.

Ultrasonic Scalpels - High-precision surgical tools for minimally invasive procedures.

Surgical Staplers - Reliable performance in medical suturing applications.

Other Surgical Instruments - Ensuring precision and longevity in medical procedures.

Engineered for Medical Excellence - Trusted by Professionals Worldwide!

Chemical Composition Chemical Composition

ASTM F136 Ti-6Al-4V ELI Chemical Requirements:

| Element | Composition,% (mass/mass) |

| Nitrogen (Maximum) | 0.05 |

| Carbon (Maximum) | 0.08 |

| Hydrogen (Maximum) | 0.012 |

| Iron (Maximum) | 0.25 |

| Oxygen (Maximum) | 0.13 |

| Aluminum | 5.5-6.50 |

| Vanadium | 3.5-4.5 |

| Titanium | balance |

Mechanical Properties Mechanical Properties

ASTM F136 Ti-6Al-4V ELI Annealed Mechanical Properties:

| Diameter in(mm) | Tensile strength Min, psi (MPa) | Yield strength(0.2%,offset) Min, psi (MPa) | Elongation in 4D or 4W Min (%) | Reduction of Area Min (%) | ||||

| L - | LT - | ST - | L - | LT - | ST - | |||

| <0.187 (<4.75mm) | 125000(860) | 115000(795) | 10 | ... | ... | ... | ... | ... |

| 0.187~1.75 (4.75~44.45mm) | 125000(860) | 115000(795) | 10 | ... | ... | 25 | ... | ... |

| >1.75~2.50 (44.45~63.50mm) | 120000(825) | 110000(760) | 8 | ... | ... | 20 | ... | ... |

| >2.50~4.00 (63.50~101.60mm) | 120000(825) | 110000(760) | 8 | 8 | 8 | 15 | 15 | 15 |

Tolerance (mm)

ASTM F136 Ti-6Al-4V ELI Tolerance:

| Diameter(mm) | Thickness tolerance(mm) |

| >3~6 | 0,-0.012 |

| >6~10 | 0,-0.015 |

| >10~14 | 0,-0.018 |

| >14~18 | |

| >18~24 | 0,-0.021 |

| >24~30 | |

| >30~40 | 0,-0.025 |

| >40~50 | |

| >50~65 | 0,-0.030 |

| >65~80 | |

| >80~100 | 0,-0.035 |

| Titanium Bar/Rod | Titanium Wire | Titanium Disc |

| Titanium Ingot | Nitinol/Nickel Titanium | Artificial Joint Castings |

About Bokang

Our Advantages

FAQ Q: Are you a manufacturer or a trading company?

A: We are a direct manufacturer with 18+ years of experience in titanium production. Q: Do you provide free samples?

A: Yes, we offer free samples, but customers need to cover the shipping cost.

Q: What is the minimum order quantity (MOQ)?

A: 1 kg. We maintain a 20-ton monthly production capacity for titanium rods and wires, ensuring sufficient stock for standard medical and aerospace materials.

Q: What titanium products do you offer?

A: Our product range includes pure titanium, titanium alloys, titanium rods, wires, discs, sheets, plates, nitinol alloys, and more.

Q: What are your payment terms?

A: Payment terms vary based on the transaction type (FOB, CIF, CNF, etc.).

For mass production, we require 30% deposit before production and 70% balance against shipping documents. We accept T/T and L/C payments.

Q: What industries do your products serve?

A: Our titanium and nitinol alloys are widely used in medical, aerospace, and industrial applications.

Q: How can I get a price quote?

A: To provide an accurate quote, please provide the following details:

1 Product Name

2 Standard

3 Material Grade (Chemical Composition)

4 Dimensions

5 Quantity

Q: Do you offer custom manufacturing?

A: Yes! We provide customized titanium products based on customer drawings or samples.

Q: How do you ensure product quality?

A: We implement strict quality control at every stage of production, using advanced testing equipment to meet customer and international standards.

Q: What are your shipping options?

A: We ship via sea or air, depending on customer requirements.

Contact us today for more details or a custom quote!

>> Tractor Mounted Rock Picker Stone Picker Price

>> Stainless Steel 316 Hexagonal Hole Perforated Metal Mesh Sheet

>> Farm Use Straw Alfafa Grass Crushing Equipment Large Capacity Rotary Hammer Mill Straw Grass Bale Crusher

>> Industrial Ball Mill for Processing Slag and Sand Materials

>> Automatic mineral pure alkaline water bottling machine / filling equipment production plant filling line price

>> Tactical G3 Frog Suit Uniforms Quick Insert Type Guard Knee and Elbow Pads

>> cupboard tea large metal kitchen storage trays organizer

>> Stylish Loose Lace Waist Swing Skirt for Fall Fashion

>> CNC Drilling Machine for Plates Model PLD2012 Steel Structure Plate Drilling Machine

>> Estop Eta50100nc Economical Grinding Machine Saddle Type Surface Grinding Machine

>> Yagi Directional Antenna Stainless Steel Yagi Antenna Stainless Steel150-2700MHz (1)

>> Factory Price Animal Feed Powder Machine Production Line

>> Model SP3818 Hot Runner System for Injection molding machine

>> Large Capacity 45 Tons Hydraulic Excavator: Ideal Choice for Contractors

>> Taijia Factory Direct Supply Ultrasonic Pulse Velocity Concrete Tester ultrasonic pulse detector tester

>> Lugong Hydraulic Transmission Cutter Mini Excavator Small Digger with Cheap Price Lz08

>> Special Craft Beer with Green Tea Taste in New Bottle Can

>> Work Gloves & Knitted Gloves & Labor Gloves

>> Stainless Steel Industrial Temperature Gauge

>> 2016 High Efficiency clay briquetting press clay ball press mould coal fines briquette mould machine

>> Plastic PVC Powder Pulverizer High Output

>> Huatian Glass Drilling Machine/ Glass Machines (HBZ2120) K10

>> Gypsum Board Production Line Making Machine

>> 5 Pin 13A 1 Gang Wall Power Electrical Switch Socket with Light

>> Battery Powered Digital LCD display Pressure Gauge 4 LCD low power consumption

>> 3HP, 5HP, 8HP, 9.9HP, 15HP, 25HP, 30HP, 40HP, 60HP, 75/85HP Enduro Outboard Motor, Outboard Engine Replace YAMAHA, Tohatsu, Suzuki, Mercury

>> Middle Speed CNC Wire Cut Machine

>> Fa 5MP 55mm 2/3Fa 5MP 55mm 2/3" F2.8-Colse C Mount Zoom Industrial Camera Machine Vision Lens

>> Biodegradable aluminum foil doypack liquid spout pouch for soap body lotion

>> Quality Fight Gear Professional Boxing Gloves Custom boxing gloves,leather boxing gloves