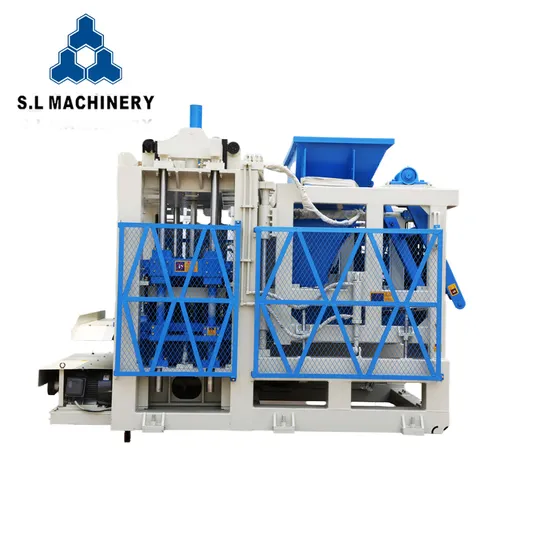

Block Making Machine Qft8-15 Hot Sales

| US$50,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

QFT8-15

Certification

CE, ISO

Customized

Customized

Automatic Grade

Automatic

Type

Vibration Molding

Color

White/Blue

Condition

New

Transport Package

Nude Package

Specification

CE ISO9001 ISO14001

Trademark

Sanlian

Origin

China

Production Capacity

50 Sets Per Month

Product Description

Block Machine Q(F)T8 -15Product Description

1. Raw material: Crushed stone, sand, cement, dust and coal, fly ash, cinder, slag, gangue, gravel, perlite and other industrial wastes.

2. Applied products: Concrete blocks. Solid / hollow / cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, kerbstones, grass blocks, slope blocks, interlocking blocks etc.

3. Applied fields: Widely used in buildings, road pavers, squares, gardens, landscaping, city constructions etc.

Product Parameters

Key Technical Parameters of the Block Machine Q(F)T8-15 1) Innovative Molding Method: Experience a revolutionary production journey with our automatic charging, vibrating, and pressing systems. Designed to significantly boost productivity and output quality, these features streamline operations for maximum efficiency.2) State-of-the-Art Control Mode: Elevate your production with our cutting-edge, fully automatic PLC control system. This advanced technology guarantees seamless and high-efficiency operations, ensuring consistent and superior performance every time.3) Optimal Pallet Size: Our well-calculated 970x880mm pallet size is engineered to fulfill a broad array of operational requirements, ensuring optimal performance and adaptability across various projects.4) Efficient Molding Cycle: With a cycle range of 15-25 seconds, it varies according to the brick type and materials used, achieving a perfect balance between speed and quality. Technical Parameters

| Model | Q(F)T10 | Q(F)T8 | Q(F)T7 | Q(F)T6 | Q(F)T4 |

| Pallet Size(mm) | 1220x900 | 970x880 | 1150X750 | 880x680 | 880x500 |

| Max. Molding Area(mm) | 1100x860 | 920X830 | 1090X700 | 830x640 | 830X460 |

| Min. Product Height(mm) | 50 | 50 | 45 | 50 | 50 |

| Max. Product Height(mm) | 250 | 200 | 250 | 200 | 200 |

| Cycle Time(s) | Solid Brick 15- 18 Paver 20-25 | Solid Brick 15- 18 Paver 20-25 | Solid Brick 15- 18 Paver 20-25 | Solid Brick 15- 18 Paver 20-25 | Solid Brick 15- 18 Paver 20-25 |

| lf the required pallet size or product heights are not listed here, we are happy to make special plans for you. | |||||

Production Table

| Model | Brick Size | Production(per mould) | Production(8h one shift) |

| Q(F)T10 | Hollow Brick/390x190x190mm | 10 | ≈14,400PCS/202m3 |

| Solid Brick/240x115x53mm | 62 | ≈100,000PCS/135m3 | |

| Paver/200x100x60/80mm | 40 | ≈52,000PCS/1000m2 | |

| Q(F)T8 | Hollow Brick/390x190x190mm | 8 | ≈11,500PCS/160m3 |

| Solid Brick/240x115x53mm | 48 | ≈80,000PCS/117m3 | |

| Paver/200x100x60/80mm | 32 | ≈44,000PCS/880m2 | |

| Q(F)T7 | Hollow Brick/390x190x190mm | 7 | ≈10,080PCS/140m3 |

| Solid Brick/240x115x53mm | 46 | ≈77,000PCS/147m3 | |

| Paver/200x100x60mm | 30 | ≈40,000PCS/800m2 | |

| Q(F)T6 | Hollow Brick/390x190x190mm | 6 | ≈8,640PCS/120m3 |

| Solid Brick/240x115x53mm | 32 | ≈53,700PCS/73m3 | |

| Paver/200x100x60/80mm | 21 | ≈29,000PCS/577m2 | |

| Q(F)T4 | Hollow Brick/390x190x190mm | 4 | ≈5,760PCS/80m3 |

| Solid Brick/240x115x53mm | 21 | ≈35,000PCS/48m3 | |

| Paver/200x100x60/80mm | 14 | ≈20,100PCS/400m2 | |

| Difference between different raw material and ratio and production mode If a cuber is required,the capacity may be affected | |||

Brick Samples

Project Cases

FAQ

Q1: Do you offer warranty on your equipment?

A1: Yes, we offer a full warranty on new equipment purchasing.

Q2: which payment terms you can do?

A2: We can work on T/T term, L/C term and T/T & L/C term:

T/T term: 30%T/T as deposit, the remainder 70% should be paid before shipment.

L/C term: 100% by irrevocable L/C at sight without "soft clauses"

T/T & L/C term: 30% T/T as deposit, the balance 100% by irrevocable L/C at sight without "soft clauses"

Q3: Where is the port of loading?

A3: Normally the port of loading is XIAMEN PORT, FUJIAN, CHINA; also it can be the main port of CHINA MAINLAND

Q4: How about the installation and commissioning on new purchases?

A4: We will send our technicians to your place to guide the installation, commissioning and training your operator. You should pay for board(meals), lodging expenses and a daily allowance of USD$200 per person per day for our service engineer ; prepare the tools (crane, welding machine and electric wrench), the power and the materials for testing work; do the foundation work before our technician arrive your work site.

Q5: How much space is necessary for brick machine, wall panel machine and concrete batching plant?

A5: Normally, a brick factory needs at least 3000m2 of land, wall panel factory needs 6000m2 land, concrete batching plant requires 3000m2 of land; the land area includes raw materials stacking, equipment area, office space, vehicle access , finished products area and so on.

Q6: The durability of the block making machine?

A6: The main steel structure equipped with Q235 heavy duty steel, it's durable.

The mould frame is made of 16 Mn steel, the press board made by 1045 heavy duty steel, can press more than 100,000 times.

Equipped with Panasonic PLC and frequency transformer; SIEMENS electric element.

Equipped witorthman hh Nydraulic pump and valves.

Under regular operation, our machines can running more than 20 years, while it depend on the daily maintenance.

In Algeria, Brazil, Egypt and Saudi Arabia, S.L MACHINERY 2nd hand block making machin are popular, so after you finish the project, you can sell it as 2nd hand machine.

Q7: How long will the delivery time take?

A7: Normally it will take about 35-40 days to produce the ordered machines. Most of the time, we can have an immediate delivery of our regular machines in 30 days.

Q8: Can I visit your factory?

A8: Of course. We warmly welcome you to visit our factory. And we provide you great services like airport pick up, hotel booking, etc.

Q9: What is your technological advantage of block machine?

A9: 1. Frequency Conversional Motor Automatic Vibration System ;

2. SIEMENS PLC System

3. Oil Cylinder Synchronously Demoulding

4. Noise & Aftershock Reduction System

5. More Homogeneous and Faster Mixture Discharging

6. Full servo production line with high efficiency and energy saving(Optional)

7. Remote monitoring equipment, timely provision of equipment failure warning

Q10: What is your warranty?

A10: We are responsible for all the repairs that caused by our quality problems within one year's warranty. Foreign accessories are generally delivered by DHL in orde to provide service for foreign customers promptly.

Q11: If the warranty expired, will you continuely to provide us after-sale service?

A11: The customers whose products have passsed its warranty date are entitled to enjoy our after-sales service for life.

Q12: What Raw Materials can be used for making blocks and bricks ?

A12: Cement, Sand, Fly ash, Coal residue, Coal wastes, Sand, Crushed Stone ,Construction wastes ,etc.

Q13: This machine can make different types and designs of blocks & bricks?

A13: Yes, the same machine can make different types and designs of hollow blocks , solid bricks, color pavers, curbstone etc. it only need change different moulds accordingly.

Q14: What is your company advantage?

A14: Our compnay has more than 30 years experience in the the field of block machine. We can not only offer you the machine but aslo the comprehensive service, one-station service.

Q15: How many countries have you sold to?

A15: Our machine has been exported to more than 102 countries and regions, up to 10,000 users

>> Flexible Bending Center Automatic Panel Bender CNC Bending Machine

>> Ypoo 38cm Treadmill Running Machine Fitness Treadmills for Home Folding Electric Treadmill OEM ODM Factory with Ypoofit APP

>> Kalmar Sensor 923976.3289 20820494 Pressure Sensor 923976.3250 20792328

>> Mobile screw gold trommel screening plant popular in Ghana Australia Bolivia Brazil

>> 4FT Rotary Cutting Machine Log Debarker Veneer Making Machine Veneer Peeling Line

>> Mini flow wrapping machine small pillow packing machine total 2 meter long

>> Best Selling Ball Cage Retainer Ball Guide Durable Retainer Bearing Cage Sleeve

>> Aluminum/Plywood/MDF Panel PVC Film Sticking Laminating Machine

>> Water Aquatic Barbell Aerobics Dumbbell Pool Aqua Exercise Fitness EVA Barbell Aquatic Swim Bars and Dumbbells Pool Aerobics Bl20167

>> High Speed Double-Layer Napkin Folding Machine Restaurant Paper Towel Machine

>> Dish Rack and Drainboard Set for Kitchen Counter, Large Rustproof Dish Drainer with Removable Water Tray, Utensil Holder

>> Hydraulic Cutting Machine Waste Scrap Sheet C Shears Q43 Series Scrap Metal Recycle Alligator Shear Machine Type Alligator

>> 2025 Hot Sale Large Panel Xxx Vidio LED TV 50 55 65 75 Inch Smart TV Android FHD 4K Customized LCD OLED TV for Sale

>> 210W CIGS Flexible Solar Panel (Flex-03M-1.7M)

>> Medium-Duty Disc Harrow Working Width 2000 mm

>> Woodworking Machinery Power Tools Professional CNC Stone Engraving Router for Marble Granite Cutting Machine Price

>> Solid Hard 10 mm PVC Poly-Vinyl Chloride Sheet

>> Industrial Water Softener with Water Softening and Pretreatment Features

>> W12 4 Rollers Hydraulic Plate Rolls Sheet Metal Rolling Machine

>> High Quality Corrosion Resistant Industrial Titanium Plates Titanium Plates for Chemical and Marine Engineering

>> Tractor with Front Rear Combined Stalk Mulcher

>> 2024 New Fur Slippers Women Winter Plush Sandals Luxury Slip on Platform Slides Female Thick Sole Designer Cotton Home Shoes

>> Film Faced Plywood Hot Press Machine Veneer Press Machine

>> Auto Body Collision Measuring System Factory Direct Manuel Measurement Tool Wholesaler

>> IP65 Wedding Stage Lighting Wireless Waterproof Battery Flat PAR Light

>> YAMAHA SS 8mm FEEDER KUJ-MC100-000 KHJ-MC100-000 KHJ-MC100-002 for pick and place machine

>> Molded Hot Press Compressed Wood Pallet Making Machine Sawdust Wood Pallet Making Machine

>> Wholesale 8040 FRP reverse osmosis membrane shell membrane shell 4040

>> anti-floating aeration system tubing air hose self sinking 3/8\

>> Teng Zhou Milling Machine Manufacturer for Sale X5040