Solid Phase Thickening Drying Machine for Pet

| US$33,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

RS-SSP

Material Processed

Plastic Flakes

Plastic Type

PET

Screw

Multi-Screw

Automation

Automation

Computerized

Computerized

Certification

QS, GMP, ISO9001:2008, CE

Function

Viscosity Increase

Output

2-46tons

Electrics

Globle Famous Brand

Control Method

PLC

Working Time

24hrs One Batch

Usage

Pet Intrinsic Viscosity (IV) Increasing Machine

Purpose

Pet Bottle to Bottle Technology Include Pet Viscos

Transport Package

Standard Export

Specification

80m3

Trademark

rongsheng

Origin

Zhangjiagang

HS Code

84778000

Production Capacity

150sets/Year

Product Description

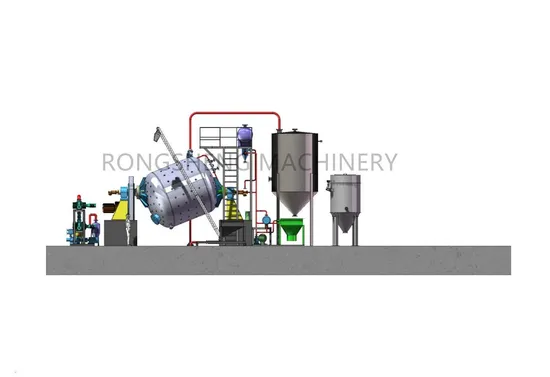

Product DescriptionRecycled PET Intrinsic Viscosity (IV) Improves Machine (SSP)

Pet Straps Packing Belt Pet Packing Strapping IV Improve PET Solid State Polycondensation Equipment

Improve PET Viscosity (IV) PET Intrinsic Viscosity (IV) Increasing MachineThe solid state viscosity increasing device consists of: drum reactor, thermal oil heating and cooling system, vacuum system, electrical PLC (or DCS) control, etc.

The increase in IV(Intrinsic Viscosity) is based on the molecular characteristics of the copolymer. At the critical temperature, thanks to the special extreme vacuum technology and high-precision temperature control, small molecular weight chemicals will be extracted along with the vacuum pipeline and the copolymer molecular chain will be extended so that In order to meet the requirements of increasing viscosity, IV(Intrinsic Viscosity) can be steadily increased and high-purity and high-viscosity PET can be obtained, which can be used in spinning, industrial yarn, POY, FDY, packaging sheet, preform production and bottle-to-bottle recycling.

Increasing PET chips Viscosity Solid-State Polycondensation Equipment Ssp Machine

Improve PET Viscosity (IV)

PET Bottle to Bottle Technology Include PET Viscosity Improve Machine

Ssp IV Increase System for Pet PET Bottle to Bottle Technology Include PET Viscosity Improve System

Product Parameters

Machine model: From 5 L to 46 cubes, Customized according to production capacityOut-put capacity: From 1Kg/ batch to 23000kg/ batchOne batch time: 26 hours to 36 hours (Depends on target IV and original IV)

Certifications

Packaging & Shipping

Company Profile

After Sales Service

After all machines are delivered to customer's factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.Rongsheng will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.Engineer will give free training lessons to labors in buyer's factory.In some countries like India, Vietnam, we have local person who can go to customer factory for machine installation and testing.

Our Advantages

1. We are a original factory.

2. We have our own technical team

3. We can provide a complete set of solutions, SSP, LSP, washing and recycling machine, bottle to bottle, pelletizing machine.

4. We can provide upstream and downstream solutions, such as recycling equipment, granulation equipment, dryer, conveyor. 5. You can visit local equipment directly in some countries.

6. If you come to visit our company, we can take you to vist running machines in customers factory in China. To prove our company's professionalism and the good quality of our company's equipment.

>> Brand New Fashion Soccer Shirt Made To Order From 2022 Best Supplier

>> Bar Rebar Truss Lattice Girder Beam Welding Machine Production Line

>> Zebra / Symcode Portable Wireless 2D Li4278 / Ls4278 Barcode Scanner

>> Railway Freight Transport From China to Europe

>> 8.4 Uconnect Radio Navigation Touch Screen for RAM Dodge Jeep Chrysler La084

>> 4 Cavity Plastic Pet Mineral Water Bottle Blowing Making Machine Price

>> Custom OEM T/C Polyester-Cotton Ribbon 3D Puff Gold Foil Printed Ribbon

>> GF780ceh Full Automatic Plastic Chair Horizontal Injection Molding Machine

>> Professional Colorful WiFi APP Weather Station

>> Trendy Vegan Leather Bucket Bag with Adjustable Shoulder Strap Pockets-Fashionable Bucket

>> 100% Virgin Material 4X8 Feet portable Easy Cleaning Wear Resistant and Anti Impact HDPE Sheet Temporary Road Mats

>> Factory Direct Brass Electric Shut off Solenoid Valve for Gas

>> Industrial Steel Sheet Cutter for Maximum Precision in Cutting Tasks Slitting Machine for Steel Coil Slitting Line

>> Ruipuhua Automatic Packer Bakery Bars BIscuits Cookies Horizontal Plastic Bag Cake Bread horizontal pillow packaging machine

>> Comprehensive Metal CNC Machining Services for Global Buyers

>> Type D Marine Anti-Collision Sealing Rubber Strip and Dock Protection Rubber Strip for All Kinds of Ships, Yachts and Yachts

>> CE Approved Electrical Heater Car Body Paint Spray Booth

>> Imported Used Forklifts for Sale Tcm Komatsu Toyota Used Forklift for Sale

>> Yj-90b Semi Automatic Visua Vial Inspection Machine with PLC Touch Screen

>> Artificial Tree China Indoor Outdoor Landscaping Faux Trees Artificial Pine Tree

>> Beautiful Personality Creative Famous Character Model Chaplin Home Decoration Resin Material Crafts

>> Wholesale customized disposable clip cap Non-woven Medical disposable bouffant cap

>> 550W Half Cut 144 Cells High Efficiencty Mono Solar Panel Price

>> Air Cleaner Hose For GENERAL MOTORS 96553533 For DAEWOO 96 553 531

>> Biomass Shredding Machine Wood Chip Hammer Mill Wood Crusher Machine

>> Wholesale 4000W 6 Seater Electric ATV Golf Cart Electric off Road Cart for 80km

>> Wholesale Beauty Photographic Selfie LED Ring Light with Tripod Stand for Live Stream Makeup Youtube Video

>> Plastic Waste Scrap Machine PP PE Film Recycled Granulating Pelletizer

>> Factory Price H10/H11/H12/H13/H14 Separator HEPA Filter in China for Air Purifier for Industrial Air Filter

>> CNC Machined Parts Milling Turning Tooling Services Mechanical Parts