45 Degree Cutting Stone Cutting Water Jet Porcelain Tile Cutting Machine

| Negotiable | 1 Set (MOQ) |

Basic Info.

Model NO.

HEAD4020BA-5 axis AC

Type

Hydraulic Cutting Machine

Usage

Ceramics, Glass, Fire Brick, Red Brick, Jadestone, Cement Brick, Concrete Curb, Granite, Marble

Application

Machinery & Hardware, Construction, Stone Industry

Source Voltage

380V

Automation

Semi-automatic

Cutting Ability

High Speed

Control

CNC

Certification

CCC, ISO, CE

Intensifier

Imported From USA

Shift Mode

Electrical Shift

PLC

Siemens

Power Supply

380V/50Hz

Max Water Discharge

3.8L/Min

Dimension(L*W*H)

3000mm*2000mm*150mm

Transport Package

Wooden or Softcase

Specification

3000-6000kg

Trademark

HEAD

Origin

China

HS Code

84565000

Production Capacity

30sets/Month

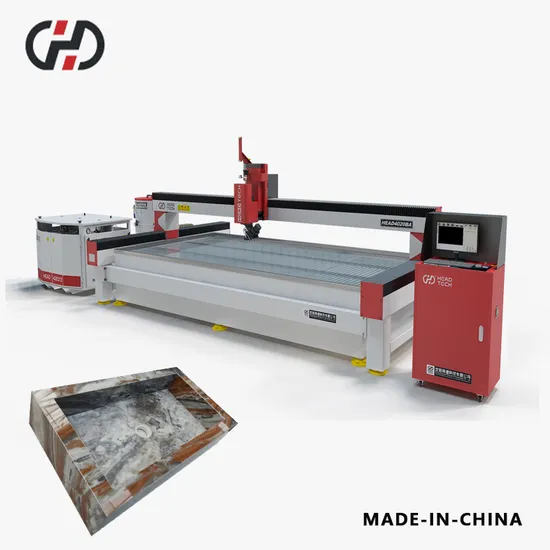

Product Description

Product description:Do you want to know how is a slab changed in to the beautiful counter tops in your kitchen?

Now HEAD water jet company will give you the answers, we have developed the complete solution of water jet cutting machine for the cutting work, until now 80% of HEAD customers in the stone industry are using the solution, and get very perfect work. Let us together see how is the machine like.

To update the countertops work, we have developed the update functions to finish all the work.

Advantages AC five axis cutting head

The highest level components in water jet, can do the tilt angle cutting, max can be 45 degree.

Loading system

It is our patent for the slab cutting, and just for protect the broken during loading.

Height measurement with laser

The laser sensor can check and test the stone slab surface height and transfer the data to CNC controller system. and then CNC can control the cutting head height to stone slab surface to ensure cutting quality of stone slabs.

Cutting sample

Many of our customers get a good cutting result by our machine, the following photo is the work they do.

Our Service

1. Maintenance free of charge for 12 months .

2. We will provide the consumable parts at an agency price.

3. 24 hours online service, free technical support.

4. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

5. We have manual instruction and Videos for software Installation, operation and machine's using and maintenance; We will send professional technician to customers' factory, provide them two-weeks training, including working principle of machine, Auto CAD drawing, common problems and solution, etc.

Our Package (soft package or wooden case)

1. Our Wooden Case is after fumigation treatment. Needn't timber inspection,saving shipping time.

2. All the spare parts of the machine were bovered by some soft materials,mainly using Pearl Wool.

Avoiding all damages that could happen in the delivery process.Then we'll covered plastic wrap out it tightly, make sure intact of the covered soft materials,also avoiding Waterproof and rust proof.

3. The outmost is Wooden Case With Fixed Formwork.

4. The bottom of the wooden case has firm iron jack,convenient to Handling and transport.

FAQ

What materials or work pieces must be cut with a water cutter?

Profile cutting of metal, the thickness of more than 50mm to 150mm water jet cutting is more advantageous.

Kitchen and bathroom countertops, now available in a complete range of configurations, are very much in the mainstream.

Bathroom glass door handle, folding hole cutting, can be used in conjunction with the glass production line.

Cutting of composite materials such as Bakelite, GRP, FRP, Nylon, etc. reduces pollution without dust and gas.

Some special metals, titanium alloy must be cut with water cutter, other cutting methods can not be cut.

Automotive interior, seats, chassis, etc., with robotic arm, now widely used.

HEAD WATER JET MAKES CUTTING IS NO LONGER PROBLEM !

>> Best Price Papaya Extract Powder Papain Enzyme

>> HDPE Water Pipe DN20-1600 Pn6-16 Thickness 2mm-150mm for Water Supply / Irrigation / Drainage / Sewerage / Gas Transport

>> Automatic Washing Powder Detergent Powder Plant Post Blending Detergent Powder Production Line

>> Smart Pet Drink Fountain, 4L Capacity, Dual Power Supply, Intelligent Sensing, and Multiple Water Modes

>> Corn Soybean Seeder Planting Machine Farm Planter

>> Rice Combine Harvester Mini Harvester

>> Children′s Wooden Color Number Recognition Classification Magnetic Mechanism Maze Educational Toy

>> Kg800 Single & Double Coil Explosionproof Solenoid Valves 12V 24V

>> Disposable NonWoven hairnet Colorable/White/Green/customized disposable Head Clip Cover

>> Wholesale White Powder Chlorinated Rubber Chlorinated Natural Rubber

>> SMA to ipex/UFL RF cable assembly rp sma extension cable Pigtail 1.13 RF Cable 10cm

>> Automatic Paper Bowl Machine for Fast Food/Noodle/Salad

>> 2025 Custom Colorful EVA Swim Pull Buoy with CE/RoHS/Reach Certification

>> House Toilet Brush with Toilet Paper Holder

>> 4lz-4.0e 88HP World Brand Mini Paddy Rice Combine Harvester

>> 300-3000d High Tenacity PP Yarn/Polypropylene Yarn for Industrial Filter Cloth

>> C6236h Steel Mechanical Lathe Machine with Good Price

>> Beauty Cosmetics Foot Care 4 in 1 Rose Crystal Foot Mask Cream Scrub Soften Exfoliating

>> Pure Raw Materials Colored PE Plastic Rod for Gear Processing

>> Alloy 8011 Color Coated Prepainted Aluminium Coil for Easy-Open Can Lid

>> Stand Style Picosecond Laser Tattoo Removal Machine Fast Effect

>> Plastic PE/PP/HDPE/LDPE Film/Bag/Woven Bag/Non Woven/Fiber/Granulating Line/Granulation Plant/Agglomeration Recycling/Compact Pelletizing Machine

>> China Fresh Ginger 150g 300g

>> 2018 Newest Lift Glass Big Panoramic Elevator for Sale

>> 6W IP65 Outdoor Lighting Aluminum Wall Washer Floor Garden Lamp Landscape Path LED Spot Light Fixtures for Garden Wall Building

>> Chocolate Chips Making Machine Chocolate Buttons Drops Machine Chocolate Drop Production Line

>> High-Power 62cc and 71cc Handheld Cultivator Tiller for Garden

>> Factory Directly Supply Favourable Price Widespread 3 Ply Earloop Medical Adults Face Mask Disposable Medical Face Masks

>> MAICTOP car accessories interior decoration air conditioner controller for land cruiser fj200 2016

>> Toyo-Intl High-Quality Vb Type Manual Lifting Chain Hoist 0.5t-50t