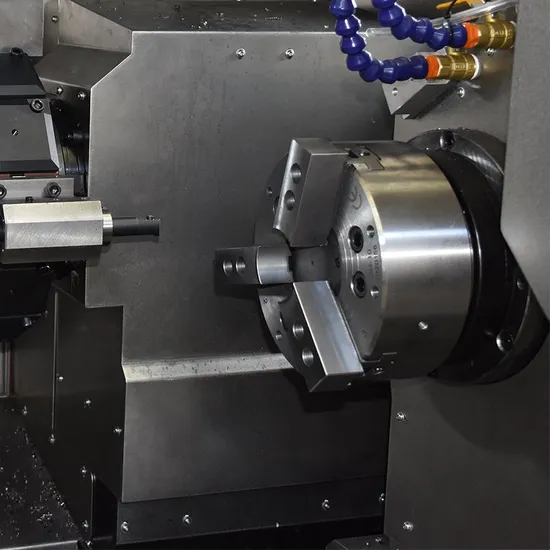

Heavy Process CNC Machine Lathe From China Taiwan CNC Lathe with X/Z/C and 12/12 Power Tool Turret with Live Tooling

Basic Info.

Model NO.

TS-8-DII

Type

Multi-Axis Automatic and Semi-Automatic Lathe

Processing Accessory

Chuck CNC Lathe

Guide Rail

Horizontal Guide Rail

Tool Holder

Double-tool Holder CNC Lathe

Power Source

Hydraulic Pressure

Controlling Mode

CNC

Automatic Grade

Automatic

Setting Mode

Floor-type

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

CNC or Not

CNC

Model

Ts-8-Dii

Name

Dual Spindle Channel Turning&Milling CNC Lathe

Key Words

CNC Machine Tool Equipment

Max. Swing Over Bed

550mm

Machine Type

Dual Spindle/Power Turret Horizontal CNC Lathe

After-Sales Service Provided

Online Support& on Site Repair

Spindle Speed

1-2500 Rpm

Application

Material Processing

Weight (Kg)

7200

Brand Name

Das Own Brand

Color

Customers′ Requirement

X/Z Axis Travel

500/580

Turret Type

12 Stations Hydraulic Power Double Turret

Repeatability (X/Y/Z) (mm)

0.005

Transport Package

Wooden Box Package

Specification

3800*2400*2000 mm

Trademark

DAS

Origin

China

HS Code

8458110090

Production Capacity

20 Sets/Month

Packaging & Delivery

Package Size

3800.00cm * 2400.00cm * 2000.00cm

Package Gross Weight

7400.000kg

Product Description

DAS TS-8/10DII Large Travel Dual Spindle Dual-Channel CNC Lathe with Dual Power Turret Product Description1.Power tool with single drive mechanism can be mounted in all positions Maximum torque of 25N m for heavy-duty cutting Increased number of tools, 2nd turret that can be equipped with.

2.The number of tool mounting faces has been increased to 8 from 6 on previous models. In addition, a double plane tool mounted,allowing a significant increase in the number of tools to be mounted, In addition,up to 4 powerhead tool holders can be installed.

3.The 1st turret and 2nd turret can machine both the 1st spindle and 2nd spindle simultaneously, allowing for higher machining efficiency.

4.By overlapping control of the 2nd spindle movement command,which can move in the X/Z direction,with the lst turret's axis movement command, machining time can be significantly reduced.

| Model | TS-8-DII |

| Max.swing diameter(mm) | 550 |

| Max.cutting length(mm) | 600 |

| Max turning diameter(mm) | 300 |

| Spindle nose | A2-6 |

| Spindle speed(r/min) | 0-2500 |

| Spindle power(kw) | 11 |

| Tool installation | BMT65 |

| Max.number of tools(pcs) | 12 |

| X1/Z1 axis travel(mm) | 500/580 |

| X2/Z2 axis travel(mm) | 500/580 |

| X1/Z1 axis servo motor power | 3.9/3.9 |

| X2/Z2 axis servo motor power | 3.9/3.9 |

| Guide form | Linear guide way |

| X/Z axis axis fast moving speed(m/min) | 20/20 |

| Hydraulic station motor power(kw) | 3.75 |

| Pump motor power(w) | 750 |

| Spindle bore(mm) | Φ62 |

| Sub-spindle bore(mm) | Φ62 |

| Net Weight(KG) | 7200 |

| Machine Power(kw) | 44 |

| Machine Dimensions(LxWxH)(mm) | 3800*2400*2000 |

1. Machine tool control system uses Taiwan SYNTEC 6TA-T3S system. Other Brand including GSK,Fanuc,Siemens are OK!

2. Machine body is cast in one piece. The lathe bed tilts by 45°and the inclined placement of lathe carriage.

3.Taiwan's high-precision spindle, comprising Japan NSK precise bearings; three-jaw hydraulic chuck or other elastic clamp can be directly fitted on the main shaft flange.

4.The drive part of machine tool uses HIWIN/PMI high precision P3 class ball bearing screw and high speed linear slide rail.

Good Feedback

Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. is located in Chencun, the important machinery town in Shunde District,Foshan. Sticking to the human-centering management, we are in possession of a group of highly competent technical personnel, a market oriented experienced sales team. In the gesture of sincere cooperation, we strive to establish a promise keeping and quality .

Our major products include CNC series gang tool type lathes , turret lathes, take heart-type lathes and milling-type lathes, featuring space saving, low cost and diversified arrangement etc.

They can also meet the demand for precise processing of different products. The products find widespread application in the manufacture of cars, motorcycles and accessories thereof,electronic industry, optical instruments, clocks and watches as well as special motors etc.

We have precise lathe equipment, complete quality guarantee system, prompt goods supply as well as perfect after-sales service,which ensure us the first consideration when you purchase high-precision machine tools.

>> Gas Pipeline Sch40/Sch80 High Pressure Boiler Tube 321 304 316 Seamless Steel Pipe

>> Unisex Large Cowhide Black Deformed Backpack Metal Buckle Large Capacity Backpack Backpack

>> Hot-Sale Drill Machine with Magnetic Base Mr-B16

>> Customized Design Automatic Pass Lift Stop China Villa Home Garage Car Elevators

>> Horizontal Metal Universal Manual Lathe Machine Cw6163q Heavy Duty Lathe Machine

>> Lashing Ratchet Straps

>> New CPU and GPU Cooling Fan Aspire V5-471 V5-471g V5-531 V5-531g V5-571 V5-571g V5-571p CPU Fan

>> LPG Tanker Transportation Truck for Sale

>> High Speed 353cfm Electric Motor 172mm Sunon 109e1724c501 17251 Aluminium Alloy DC Fan

>> High-Quality Workout Dumbbells for Effective Home Gym Training

>> Reliable Welding Tube Mill, Well-Maintained and Efficient, Providing Accurate Tube Producing

>> New! 72V 130kmh 100KM range120kg motorcycle with 10KW electric motorcycle in wheel hub motor electric motors brushless

>> Jwell China HDPE Plastic Water Storage Tank Drum Barrel Container Extrusion Blow Molding/Moulding/Making Machine Manufacturing with High Quality

>> Easy Assembly Metal Frames Black 18" Full Twin Double Metal Folding Bed

>> Egg Washer Machine Small Egg Washing and Grading Machine for Farm Use

>> Stand Steel Straight Shear Long Paper Cutting Machine Blades Polar Paper Cutting Blade Guillotine Blade

>> 4K E40 Et18 250W Metal Halide Lamp/Metallic De Vapor 250W

>> Hengxiang A4 Copy Paper - 210mm * 297mm - Ideal for Printing

>> Jacket Jacket Men′s New Spring Fashion Brand Loose Contrast Hooded Jacket American Functional Outdoor Tooling Jacket

>> ABB Flakes PE Film Strength Waste Plastic Recycling Machine

>> Orignal Germany Ral Color Card K7 International Standard Ral Color Card

>> Limited Stock! Hydraulic Design - Hematite/Limestone/River Pebble Crushing Machine

>> Hydraulic Press Machine for Rubber Wrist Band O-Ring Products (KS200HF)

>> Second-hand machine, used mindray Urinary Sediment analyzer mindray EH-2050A plus with good price

>> Safety Anti Skid Perforated Metal Grating for Stair Treads

>> Automatic Incubator Control Xm-18e Controller for 88-5208 Egg Incubator

>> High Precision And Quality XA7150 Bed Type Milling Machinery

>> Aluminum Expo Stands 3*3 Size Display Expo Exhibition Booth Stand for Sale New Design Fashion

>> AISI 201 304 316 430 310 2b/Ba Stainless Steel Sheet

>> Strong Vibration on Foot Sole Best Foot Massage Experience Foot Massager with Stable Heat Kneading Full Wrapped Air Massage