Five Rows Multi Boring Machine Woodworking Machinery Wood Drilling Machine

| Negotiable | 1 Piece (MOQ) |

Basic Info.

Model NO.

TQS-505AM

Controlling Mode

CNC

Automatic Grade

Automatic

Precision

Precision

Certification

CE, ISO

Energy Saving

Energy Saving

Warranty

1 Year

Customized

Customized

Condition

New

After-sales Service

12months

Panel Length

220mm-2000mm

Panel Thickness

8mm-40mm

Qty.of Vertical Row

3

Qty.of Horizontal Row

2

Working Width of Single Board Processing

35-670mm

Working Width of Double Board Processing

35-320mm

Qty. of Drill Spindle

105PCS

Max. Drilling Depth

40mm

Standard Bits Length

57mm/70mm

Holes Pitch of Y Axis

32mm - 672mm

Board Thickness

8mm - 40mm

Collet Diameter

10mm

Max. Drilling Diameter

13mm(Multi), 35mm(Single)

Rotation Speed

2840rpm

Voltage

380V / 50Hz 3 Phase

Transport Package

Package

Specification

4070mm*2580mm*1628mm

Trademark

TQS

Origin

China

Product Description

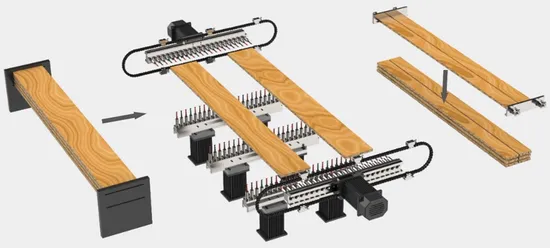

Production Description5 ROWS MULTI BORING MACHINE

Features:the machine can process 3 sides in one time, to enhance the working efficiency. Including:right & left horizontal boring units, 3 rows vertical boring unit, board storage device, chain type auto-feeding device, automatic board stacking device (optional). Can achieve three sides boring for furniture making in one time, can achieve13-16 pcs board processing per minutes.. Vertical rows movement with digital display device, to ensure the precise positioning. Suitable to process the narrow boards in the furniture industry, like the frame boards of drawer, base board of cabinets etc.

Specification

| Board length | 220mm - 2000mm | Board thickness | 8mm - 40mm |

| Qty. of vertical row | 3 | Qty. of horizontal row | 2 |

| Working width of single board processing | 35-670mm | Processing efficiency | Single board:13-16 pcs/min |

| Working width of double boards processing | 35-320mm | Double boards:20-26 pcs/min | |

| Working width of three boards processing (optional) | 35-150mm | Three boards:36-40 pcs/min | |

| Qty. of drill spindle | 105 pcs | Collet diameter | 10mm |

| Max. drilling depth | 40mm | Max. drilling diameter | 13mm(Multi),35mm(Single) |

| Standard bits length | 57mm / 70mm | Rotation speed | 2840rpm |

| Holes pitch of Y axis | 32mm - 672mm | Holes pitch of X axis | 220mm - 2000mm |

| Total motor power | 8.25Kw | ||

| Working pressure | >0.6mpa | Voltage | 380V / 50Hz 3 phase |

| Weight | About 1150kg | Dimension | 4070mm*2580mm*1628mm |

Body frame has been done the annealing treatment, in order to release the stress, and increase the extension, meanwhile will get the stable structure.

Body frame

The body frame is composed by solid welded structure and cast iron parts, so can ensure the using life of the machine.

Board Storage Device

In order to achieve high efficiency, AM series come with board storage device, cooperate with board pusher can achieve the automatic board feeding.

Chain Feeding Device

The machine come with chain feeding device, with board pushers and position blocks.

According to different working condition, the board pusher and position blocks can be one or two.

Drill unit details Adopts Taiwan original drill pack, which has been done three-coordinate detection, quality is guaranteed.

Configuration:3 group vertical rows, 1 group left horizontal row, 1 group right horizontal row

Board Pressing Unit

The board pressing unit is adjustable, to suit the different board thickness, can cut down the pressing time and increase the efficiency.

Ball screw transmission system

Adopts ball screw transmission system, which can ensure the movement accuracy, also can achieve the rapid motions

Board Position Blocks

The machine come with two pcs position blocks (three pcs as optional), the position of the blocks can be adjusted manually.

The block can do the accurate board positioning, to achieve the multi boards processing in one time.

Drill bits holder

The operation can reserve the common drill bits in the drill bits holder, which is convenient to do the drill bits changing, the capacity is 45 pcs.

Automatic board stacker (Optional)

The machine adopts automatic board stacking device, which can be connected to the production line, the stacking width will be 40-600mm.

If choose this device, the productivity will increase 25%

Drill bits holder

The operation can reserve the common drill bits in the drill bits holder, which is convenient to do the drill bits changing, the capacity is 45 pcs

PLC Control System

The machine come with PLC control system with touch screen, the brand is Shihlin brand from Taiwan.

With human-friend HMI, which is easy to operate. With multi languages options

Lubrication pump

In order to extend the using life of the linear guide way, the machine come with manual lubrication pump.

Control Cabinet Adopts Shihlin brand inverter and PLC to ensure the stability of the control system.

Circuit breaker is from Schneider, AC contactor is from SIEMENS, which can ensure the stability of the circuit.

1. What's your guarantee? Which type of after-sale service can you provide to us? All the machines, we can offer a 1-year guarantee to our customers; any parts damaged due to the quality issue, we will send the parts via DHL, FedEx, or air shipment urgently. After-sale service: if you purchased our CNC nesting center or edge bander, and we don't have any dealer or agent in your region, we will send our engineer to your site for installation and training ( you should pay the round-trip flight ticket, salary of engineer- each day 100.00USD, also take charge of the local accommodation. ). Considering the situation, we can do the online training. Also any small issues, you can knock us online, we will offer the rapid action to your concerns. 2. Which type of payment term can you accept? How could we keep our capital safe? We can accept the T/T and L/C at sight. We have more than 10 years exporting experience, so we know more about the capital safety concern of our customers. We will offer the video call or pictures to your side, during our loading, then you can check what we have done for the loading, if any cheating, then you can control your payment (T/T or L/C). 3. What is the leading time, if we did the payment to your side? The leading time of most common machines will be 10-25 days after collecting the down payment/copy of L/C. Specially designed production will take little bit longer time. 4. Can you accept some O.E. M service to us? or any other service could you do for us? We have more than 15 years' experience in the woodworking machinery industry, also have more than 5 experienced engineers, so we can do the special design according to your requirement. Also, our exporting team has more than 10 years of experience in this field, so they can help you to purchase relevant products, parts, or tools, which can save your time and your cost.

>> Cryogenic Liqiud LNG Tanker Trailer

>> Cheap Price Dark Brown Whole Dry Shitake Mushroom Dried Shiitake

>> Custom Kraft Paper Stand Up Top Bag For Food Packaging Bags With Window

>> Riello Rl50/RS50 Combustion Fan Blade Burner Accessories Are Original and Genuine

>> New Design Smart Home Use Low Noise Air Purifier Uvc

>> Puppy Doll Plush Toys Cute Dog Doll Healing Girly Heart Cloth Dolls

>> Made in China 502 Glue Mixer Adhesive Reactor

>> Heavy Duty Aluminum Rollator 4 Wheels 6 Levels Height Adjustable Rollator Walker

>> Vacuum Mixer Machine, High Speed Mixer for Metal Powder Coating

>> Chinese Manufacturer FRP Glass Fiber Adsorption Tower

>> Auto High Speed HDPE LDPE LLDPE PE Two Layer Multilayer Layer Rotary ABA Plastic Film Blowing Extruder Film Extrusion Blown Machine Price

>> Customized PP Woven Big Bags Baffle PE Liner Bulk Polyethylene Liner FIBC Container Bags PE Liner Waterproof 1000kg

>> Outdoor Playground Kiddie Rides Walking Robot with LED Marquee

>> Pet Transfer Film/ Inkjet Printing Film/ DIY Printing Clothes/Hot Peeling

>> High Pressure Venturi Loader for Plastic Material Conveying Hopper Loading Machine

>> Kjt M30 NPN PNP 3 Wire Sn 10mm Shielded High Temperature Sensor Connector

>> Promotional Auto Open 16k Colorful Rainbow Golf Rain Umbrella

>> Different Method Printing Different GSM Non Woven Suit Cover for Garment

>> a++ ERP 4.0 House Heat Pump Mini Split Inverter Air Conditioning 9000BTU 12000BTU 18000BTU 24000BTU Air Conditioner

>> Australia Standard Hurricane Impact windproof Casement Insulated Window for Home Casement Window with Fixed Glass Design

>> 2024 Mingju Th800 CNC Machining Center with 800X800 mm Worktable

>> PRO Tennis Badminton Racket Grips Overgrips Anti Slip Absorbent Overgrip Band

>> Thickened Aluminum Alloy Profile Swing Door, No Rust, Can Withstand All Kinds of Harsh Environments, Such as Aluminum Frame Factory Commercial and Storage Doors

>> Gypsum Board Production Line Equipment for Forming Drywall Panels

>> Complete Sinking Fish Feed Machine Production Line for Aqua Feed Pellet Mill Machine Supplier

>> Wood Grinder Crusher Powder Making Machine Sawdust Hammer Mill

>> 5kg Capacity Electronic 5kg 1g Division Weighing Kitchen Scale Platform Scale

>> Conventional Milling Machining Parts Dowel Milling Machine Zx6350

>> Popular Carnival Inflatable Target Toss Football Dart Board Game (AQ1616-15)

>> Northtech Panoramic Slimline Ultimate Narrow Frame Aluminum Bi Folding Door / Aluminium Folding Door / Multi-Leaf Panel Door / Balcony Door/ Bi Fold Patio Doors