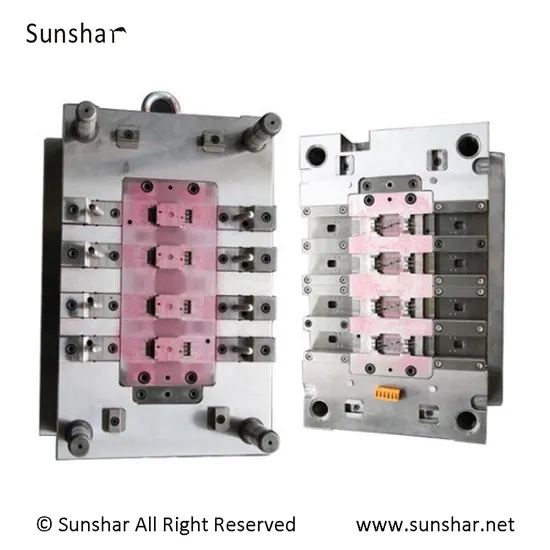

Leading Mold Maker for Precision Automotive Parts and Connectors

| US$1.00-3,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

2510

Mould Cavity

Multi Cavity

Plastic Material

PA66+GF

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Commodity, Electronic

Runner

Cold Runner

Design Software

UG

Installation

Fixed

Certification

CE, ISO

Standard

DME

Customized

Customized

After-sales Service

24 Hours

Mold Base

Lkm

Hardness

48-52HRC

Cavities

8

a/B Plate

P20

Core/Cavity

H13

Transport Package

Wooden Packing

Specification

40*45*331mm

Trademark

Sunshar

Origin

China

HS Code

8480790090

Production Capacity

100

Product Description

| SUNSHAR PRECISION TECHNOLOGY CO., LTD | |

| ADD: Shangjiao District, Chan'an Town, Dongguan City, Guangdong Province, China. 523878 | |

| Sunshar Mold / Tooling Specifications: | |

| Mould Standards: | AISI, DIN, JIS |

| Mould Base Standard: | HASCO, DME, LKM, FUTABA |

| Mould Steel: | H13, 1040, 420, P20, 0-1, S-7, D2, A2, 1.2343, 1.2344, 1.2083, 1.2311, 1.2379, 1.2510, 1.2767, 1.1730, P5, NAK55, NAK80, SKD61, SKD51, S136, S136H, 8407, M333, 718H |

| PC, PC+ABS, ABS, PBT, LCP, PBT+GF, POM, Nylon, PEEK, PE, HDPE, PP, AS, PS, PP+PULVISTALCI, PET, TPU, PPS, PSU, PPO | |

| SPI Mold Classifications: | 101,102,103,104, 105 |

| Mold style: | Mold style: 2-Plate, 3-Plate mold, Multi-Plate mold, MUD, 2K mold |

| Runner: | Sprue gate, Edge Gate, Pin Point Gate, Banana Gate, Submarine Gate, Ring Gate, Slim/Flash Gate |

| Cooling System: | cool water, oil heat |

| Hot Runner system: | MOLD-MASTERS, INCOE, HUSKY, SYNVENTIVE, YUDO, EVIKON etc. |

| Surface Finish: SPI (DME) | Polish: A0,A1,A3,B1,B2,B3,C1,C2,C3,D1,D2, Texture: Mold-tech, YICK SANG |

| VDI 3400 Standard: (HASCO) | EDM: 0,3,6,9,12,15,18,21,24,27,30,33,36,39,42,45 |

| Package: | Plastic Tray, Tape Carrier, PE bag, Carton, Poly-Wooden |

| Payment items: | 40% down payment, 40% with material ordered, 20% with T1 Samples |

| Delivery Time: | 7-30 days (Normal) |

| Shipping methods: | By DHL, FedEx, UPS, TNT etc. or By sea from Shenzhen |

Why Choose Sunshar?

Sunshar offers a comprehensive solution for high-volume and technically demanding plastic injection molding and metal stamping. We specialize in progressive stamping dies and precision metal terminals for industries such as Consumer Electronics, Smart Home Technology, Automotive Connectors, and Connector Terminals. Our expertise encompasses the entire manufacturing process, from initial product concept design to injection molding, stamping die tooling manufacturing, part production, assembly, and packaging. This allows you to focus on your core business while we handle the details. Our Advantages

Competitive Advantages

One of our key advantages is our competitive pricing, combined with advanced solutions tailored to your product designs. We strive to reduce mold/tool and production costs to help ensure your products succeed in applications such as Home Automation, Smart Devices, and Electric Vehicles (EVs).

If you're looking for a bespoke solution for your high-volume plastic injection molding or metal stamping needs, Sunshar is the ideal partner. We serve a broad range of industries, including Medical, Construction, Aerospace, Defense, Automotive, Security, Agriculture, and Personal Care. As an ISO 9001:2008 certified mold tool maker and plastic injection molding company, we possess extensive technical experience and a wide array of equipment, including capabilities in metal stamping, custom stamping, injection molding and precision engineering.

For forward-thinking companies seeking support at every stage of the product concept process, from design to custom plastic injection molding, Sunshar provides effective and innovative solutions. We ensure high-quality production of electrical connectors, metal terminals, and related components.

Benefits of Partnering with Sunshar

When you choose Sunshar as your partner, you will enjoy:

Interactive Quotes: Delivered in hours, not days. Fast Turnaround: High-quality, consistent parts delivered in days, not weeks. Free Manufacturability Analysis: Streamline your development process with every part design. Lifetime Mold Guarantee: Unlimited parts with no additional cost. No Design Restrictions: You receive exactly what you designed.

Order Process Send us the drawing with specifications for quality, mold life, and other requirements. Receive a detailed quote from us, including mold costs and part prices. Negotiate quality, price, material, delivery time, payment terms, and other details. Confirm and place an order with an initial down payment. We will analyze your products and provide a Design for Manufacturability (DFM) to ensure optimal mold and production capabilities. Send mold design for customer approval before commencing mold/tool production. Order steel materials and begin machining, with weekly updates on manufacturing progress. Assemble the mold/stamping die and conduct initial trials for sample production. Perform self-inspection and send samples along with our inspection report for customer confirmation. If the first sample meets expectations, we finalize the mold/tool. If not, we modify it until it meets your requirements. Delivery of goods by sea or air based on customer preference. Installation Instructions

Packaging & Shipping

FAQ

Frequently Asked Questions (FAQ)

Q. When can I get the price?

A. We typically quote within 24 hours of receiving your inquiry. If you need a faster response, please call or indicate this in your email so we can prioritize your request.

Q. How can I get an accurate price?

A. To provide an accurate quote, we need basic specifications, including 3D drawings in STP, IGS, or X-T format, 2D drawings with tolerances, and your desired quantity.

Q. Do you accept OEM?

A. Yes, OEM is welcome. We can customize products according to your design specifications.

Q. What shipping methods do you offer?

A. We ship by express (FedEx, UPS, DHL, TNT, EMS, etc.), by air, or by sea.

Q. What payment methods do you accept?

A. Common payment methods include T/T (Telegraphic Transfer), Western Union, and PayPal.

Q. Can you help me evaluate the manufacturability of my new product idea?

A. Absolutely! We are eager to work with potential customers to assess the technical feasibility of your design, advising on materials, tooling, and likely setup costs.

Q. What are the advantages of having my parts manufactured locally?

A. Sunshar offers quick response times to changes in specifications, batch sizes, or materials. We can ship small or large quantities anywhere in China overnight to accommodate unexpected demand fluctuations.

Q. Can I use CAD drawings for my components?

A. Yes! We can work with DWG, DXF, IGES, SolidWorks, Pro/E, UG, and Catia files to generate quotes, molds, and tools, saving you time and money.

Q. Can I test my idea/component before committing to mold tool manufacture?

A. Yes, we can create prototype parts for testing and functional evaluations based on your CAD drawings before standard mold production.

Q. What type of plastic is best for my design/component?

A. The best material choice depends on your design application and operating conditions. We are happy to discuss alternatives and recommend the most suitable materials.

Q. What type of mold or tool do I need?

A. Mold or stamping tools can be either single cavity (one part at a time) or multi-cavity (multiple parts simultaneously). Single cavity tools are ideal for smaller quantities, while multi-cavity tools are suited for larger production volumes. We will recommend the best choice based on your projected annual volume.

Q. How long will it take to receive my parts?

A. Typically, standard parts are completed within 7 to 30 days, depending on complexity and cavity numbers. After initial mold trials, parts are delivered within 2-3 days.

>> High Quality Pasta Maker Machine Fresh Wet Noodle Prodcution Line

>> Roller Quickly-Changed Welding Pipe Roll Forming Mill Heat Exchange Tube Making Machine

>> Fully automatic adjustable multiple spindle drilling machine price

>> China Type Turret Milling Machine Drill with Table Size 305X1370mm

>> 2020 Pressing PU Glue on Shoe Cover Machine

>> Poultry Farm Machinery Feed Mill Extruder Animal Pellet Machine

>> A4 235*335mm Brown PU Leather Meeting Pad PU Clipboard Meeting Clip Board Meeting Memo Writing Desk Pad, Restaurant Hotel Menu Folder Clipboard Magnetic Notepad

>> Factory Price CE Certificate Jd 9070nc Wet and Dry Industrial Automatic Wet Dust-Free Sandblast Cabinet Portable Sandblasting Equipment

>> ISO Certification Jdc350 Vertical Paddle Construction Materials Concrete Mixer

>> 5 Tons Bulk Cement Pumping Machine Deliver Bag Cement to Silo

>> Vns-10 New Design Hot Sale Russia Concrete Vibrator

>> CNC Bridge Saw Machine for Cutting Granite Marble Quartz with 3D Software

>> Factory Price Auto Parts Truck Body Parts Helper Spring Bracket Spring Shackles

>> Hot Selling Pepper Chili Powder Filling Zip Pouch Packaging Spices Flour Premade Bag Polvo Doypack Packing Machine Emballage

>> New ABS Luminous Tire Valve Cap Glow in Dark

>> Big Sale! !Low Price!!up to 50% Discount off Computer Embroidery Machine Single Head Cheap Cost Automatic Embroidery Machine 15 Needle with 1200 Spm Like Tajima

>> Low Price Stamping Press Die Punch Die for Sheet Metal Parts Jointing

>> Toggle Type for 25L HDPE Jerry Can Double Station High Speed Plastic Plastic Drum Bottle Good Quality Automatic Blow Molding Machine

>> 10cm thickness PVC plastic portable inflatable foldable fitness mat gym mat

>> Personalized Black Non-Woven Hair Packaging Bag with Hanger and Logo Print

>> UL, CE Approved Solid Shaft or Hollow Shaft Right Angle Geared Motor for Material Handling System

>> CNC Wood Milling Router with 6 Spindles Working Together

>> Wallpaper Car Sticker Label Bag Garment Digital CNC Cutting Machine

>> customized size aluminum foil food stand up zipper bag with printing

>> Anhydrous /Chemical/Natural Gypsum Powder Plaster Machine and Board Making Machine

>> Segotep Endura PRO+ Transparent Pillar Column Less Tg Glass Case

>> Gearbox Turbine Copper Telescopic German Vacuum Spares em0009 s316 Turbo Transformers 6inch Butterfly Valve Body

>> Durable Rb77wpcc Gas Generator with G3406 Natural Gas Engine

>> High Quality Recycling Rice Straw Grass Mat Mattress Weaving Machine Reed Straw Rug Knitting Braiding Machine

>> OEM Fashion 100% Polyester Cation Fleece Zip up Gym Sports Hoodie