Versatile Heavy-Duty Turning Lathes for Enhanced Production Efficiency

| US$30,000.00-110,000.00 | 1 SET (MOQ) |

Basic Info.

Model NO.

CK61125

Type

Vertical Lathe

Processing Accessory

Chuck CNC Lathe

Guide Rail

Horizontal Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Power Source

Hydraulic Pressure

Controlling Mode

CNC

Automatic Grade

Automatic

Setting Mode

Floor-type

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Transport Package

Plywood Case

Trademark

ubright

Origin

Cn

HS Code

8459619000

Production Capacity

400sets/Year

Product Description

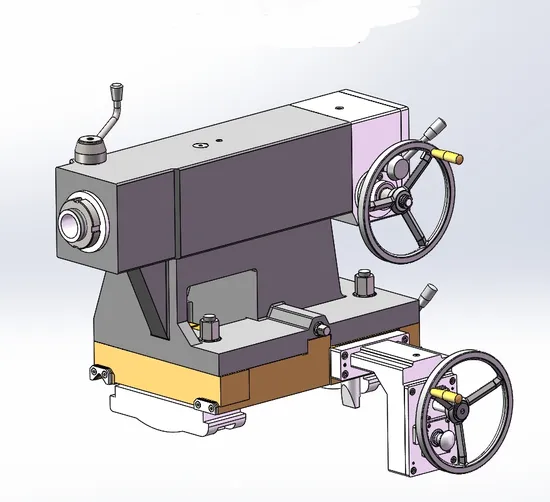

Machine PictureMachine Introduction

CK61125 Heavy-Duty Turning Lathes is a multifunctional CNC lathe developed on the basis of a large horizontal flat bed lathe. The bed is re optimized with the increased overall weight, lengthened, widened and thickened pallet, and the processing efficiency, accuracy and rigidity are better than ordinary CNC lathes.

Adopting a semi protective structure and equipped with a GSK 980TDi system. The main transmission of turning is automatic four speed continuously variable transmission, with two linked control axes.

The X and Z axes use ball screw pairs, AC servo motors, and precision reducers to achieve servo movement and semi closed loop control, with good positioning accuracy and repeatability.

This machine tool mainly consists of a bed body, headboard box, headboard box base, main motor and motor base, chuck, closed center frame, tailstock, tool holder, walking platform, hydraulic system, electrical system and CNC system, cooling system, functional components and random accessories.

Machine Applications

This machine tool is mainly capable of processing various internal holes, external circles, conical surfaces, circular arc surfaces, and threads within its processing range, and is particularly suitable for rough and precision machining of small and medium-sized shaft and disc parts.

Medium and large oil cylinders

Full process machining of wind turbine spindle

Drums in the paper industry

Crane wire rope drum

Cathode rod drum

Centrifuge drum

Efficient turning processing of precious metals such as high-temperature alloys, titanium alloys, steel ingots, rolling rolls, and laser cladding materials

Processing of thin-walled parts through processes such as external turning, internal boring, end face drilling, tapping, axial drilling, milling, etc

Machine Features

All HT300 castings bed frame, weight are 9500/ton;

Lengthened, thickened, and widened pallet slider, weighing 300 kilograms more than conventional products;

Can be equipped with a boring force seat for turning inner holes with a length to diameter ratio of 6:1 or less, with a single side of 5mm without vibration force for rough turning and up to 1.6 for fine turning.

Taking a processing length of 3 meters as an example, the total length of the bed is 5.7, and the length of the processed workpiece can reach 3 meters (taking the 3m specification as an example)

The headboard box is equipped with a hydraulic automatic four speed system (with a hydraulic station), weighing 1.6 tons, which is 200 kilograms heavier than the national standard.

Two units of 45 size linear auxiliary guide rail plus one box rail, ensuring that the tool does not vibrate when turning the maximum outer circle, and the cutting amount is large, ensuring accuracy.

The spindle diameter jump and end jump are both 0.01mm, while other manufacturers have 0.012. Bearings and spacers are customized

The X-axis screw has a specification of 5010 and the Z-axis has a specification of 8020, with stronger load-bearing capacity, rigidity, and durability Stronger accuracy retention.

Standard configuration includes Taiwan brand Intime, TBi, C3 level precision, while domestically produced products have P4 level precision, with a difference of one level

Machine Specifications

| Guide rail width | 755mm | |||||

| Maximum turning diameter | Φ1250mm | |||||

| Maximum workpiece length (outer circle of the vehicle) | 20000mm | |||||

| Weight of workpiece between two tips | 6T/8T(limited speed when heavy workpiece) | |||||

| Maximum workpiece rotation diameter on the tool holder | Φ850mm | |||||

| Spindle | ||||||

| Rear bearing | Φ200/220mm(Optional) | |||||

| Spindle speeds | ||||||

| 4 stage stepless | 1st gear | 2nd gear | 3rd gear | 4th gear | ||

| Speed range | 5~40 r/min | 20~80r/min | 40~150r/min | 80~300 r/min | ||

| Shift form | hydraulic shift | |||||

| Through-hole diameter | Φ130mm | |||||

| Spindle bore taper | Metric140# | |||||

| Spindle head | A2-15 | |||||

| Chuck size | Φ1000mm | |||||

| Chuck form | manual four jaw, single action | |||||

| Main motor | ||||||

| Main motor | 22kW servo | |||||

| Transmission form | C-type belt | |||||

| Feed rate | ||||||

| X-axis travel | 750mm | |||||

| Z-axis travel (from chuck end face to tailstock end) | 6750/7750/8750/9750mm | |||||

| X-axis fast | 4m/min | |||||

| Z-axis fast | 4m/min | |||||

| Tool holder | ||||||

| Vertical 4 station tool holder | electric tool holder | |||||

| model | LD4B-C6100 | |||||

| Tool holder edge | 300×300mm | |||||

| Section | 40×40mm | |||||

| Tail stock | ||||||

| Mode | Manual | |||||

| Mandrel diameter | φ160mm | |||||

| Mandrel travel | 300mm | |||||

| Mandrel taper hole | Metric 80# | |||||

| Overall movement form | Hanging/maneuvering | |||||

Machine Configuration

| No | Name | Model | Quantity | Manufacturer |

| 1 | Spindle bearings(P5) | 51144X | 1 | Havaló |

| NN3032K | 1 | |||

| N1036 | 1 | |||

| NN3040K | 1 | |||

| 2 | Screw Bearings | 760206TBT | 1 | Havaló |

| 3 | hydraulic component | Siemens | 1 | Chinese brand |

| 4 | Servo main motor | 22kW | 1 | Chinese brand |

| 5 | numerical control system | 1 | Siemens | |

| 6 | motor driver | 1 | Siemens | |

| 7 | Feed servo motors | 16N.m,16N.m | 1 | Siemens |

| 8 | Electric knife holder | LD4B-C61100 | 1 | Wenling Wenchang |

| 9 | ball screw | 1 | Chinese brand | |

| 10 | Main electrical components | 1 | Drexel | |

| 11 | Precision helical rack | 1 | Taiwan brands | |

| 12 | Z-axis precision reducer | 1 | Taiwan brands | |

| 13 | X-axis precision reducer | 1 | Chinese brand |

>> High Grade Cold Rolled Steel Coil Cr Strip SPCC

>> Rearview Mirror Car Side Mirror Light With Light Folding For Lexus CT200H 2011 - 2015 87910 - 76090

>> Precision CNC Machined Aluminum Parts for New Energy Equipment Services

>> frp pressure membrane housing

>> Single Phase to Three Phase Dry Type Transformer Input 220V Output 380V

>> Cwat-17 Anti Decubitus Air Tube Mattress---CE (Manufacturer)

>> Fy (A) C36-H (G) 13 Reverse Pressure Gauge Movement/Pressure Gauge Spares

>> High performance small portable gold mining equipment for sale

>> Fashion Garment Silk Lurex Fabric Silk Metallic Jacquard Fabric

>> XL6036 Horizontal Milling Machine Tool

>> Multi-Functional Large-Capacity Electrician Tool Pouch Maintenance Toolkit Hand Professional Tool Bag

>> Portable Solar LED Light Tower for Camping and Outdoor Adventures

>> Animal Feed Extruder Processing Machines Shrimp Pet Dog Food Pellet Making Machine Prawn Feed Machine Big Floating Fish Feed Machine

>> Family Party Game Inflatable Sport Slide with Air Blower

>> waterproof top glowing light new 1.5m 1.8m carp simano exspride fishing rod 10 feet telescopic

>> Dtf A3 A4 Dryer Printer Oven Dtf Heating Machine Printer Hot Dryer 2022

>> Outdoor Street Pole Digital Billboard Advertising Display LED Lighting Boxes Solar Trash Bin Advertising

>> Twin Shaft Paddle Mixer Hot Selling with High Output

>> Edge Banding Machine for Wood Furniture Plywood

>> Durable Stainless Steel Gold Color Keychain Rings with Screw Lock Design

>> Onsite Pullout Testing machine Apparatus for Concrete Anchor Rebar Pull Out Test

>> Zoyer Zy828d Safe Integrated Infrared Button Attaching Machine

>> USB to RS485 Serial Uart Converter Cable Ftdi 6 Way Wire Cable

>> High Quality M15 IP67 Waterproof 2 Pin Over Molded Cable Connector

>> Sheet Metal Roll Forming with High Precision

>> UICE Customized Efoil Electric Surfboard Powered Surfboard Hydrofoil Electric Full Carbon (Foil+Board)

>> 2021 New Style Light Up LED skipping jump rope Colorful Silicone Handles led jump rope

>> Best Quality Engine Parts Timing Belt Pulley Tensioner Roller 2445035510 24450 35510 24450-35510 Fit For Hyundai Korean Car

>> 5.8m Tender Manufacturer, 5.8m Boat, Inflatable Boat From China

>> Health medical device mini rechargeable hearing aids noise cancelling hearing aid