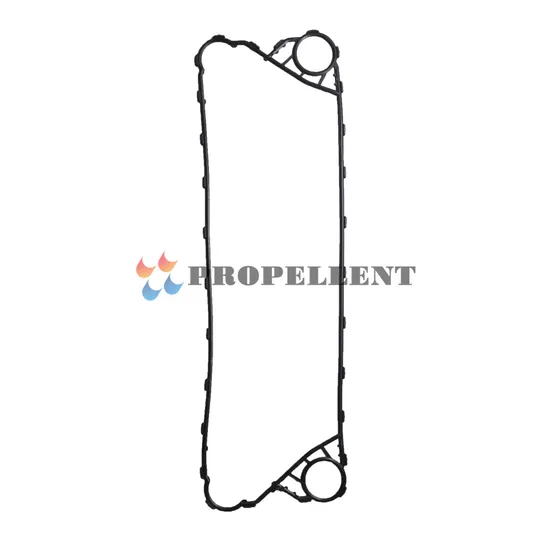

Heat Exchanger Seals EPDM NBR Gasket Alfa M3, M6, M10, M15

| US$4.50 | 100 Pieces (MOQ) |

Basic Info.

Model NO.

M15

Performance

Mechanical Sealing Strip

Gasket Type

Glueless/Clip-on

Weight (Kg)

0.17

Material

NBR EPDM FKM

Place of Origin

Shandong, China

Design Pressure

0.6~ 1.6MPa

Certification

ISO9001

Machinery Test Report

Provided

Center of Hold Distance

1294*298mm

Plate Size

1498*496mm

Application

Refrigeration Parts, Cooling,Heating

Brand Name

Propellent

Warranty

1 Year

Video Outgoing-Inspection

Provided

Max Working Temperature

160 Degress

Liquid

Water, Steam, Dairy, Sugar, Oil

Transport Package

Carton Case

Specification

EPDM, NBR

Trademark

Propellent

Origin

China

HS Code

8419500090

Production Capacity

50000PCS/Month

Packaging & Delivery

Package Size

25.00cm * 10.00cm * 10.00cm

Package Gross Weight

1.000kg

Product Description

Product Description Propellet is proud to present an exceptional range of gaskets crafted to meet every conceivable requirement in heat transfer applications. Our gaskets are meticulously engineered to excel in performance, ensuring a seamless fit onto the plate for uncompromising sealing efficiency. The superior quality of our gaskets is a testament to their thoughtfully designed architecture and the top-tier materials employed in their fabrication. The rubber compound's composition plays a pivotal role in dictating the gasket's longevity, elasticity, and suitability across various applications. Certain gaskets outperform in handling aggressive media, underscoring the importance of selecting the precise gasket for the intended application. At Propellet, we provide an extensive inventory of replacement parts for plate heat exchangers catering to internationally renowned brands such as Alfa, GEA, APV, Sondex, Tranter, Vicarb, Hisaka, API, and more, fulfilling the diverse needs of our global clientele. Product Parameters Model Number: T20BApplications: An extensive array of industries rely on our products, including Alumina, Beer, Beverage, Chemical, Dairy, Data Center, Marine, Milk, Oil and Gas, Paper-pulp, Petrochemical, Pharmaceutical, Power-plant, Refrigeration, and Waste Water, ensuring versatile and effective solutions.| Gasket Material | Temperature Range ( ºC ) | Hardness | Available Medium |

| NBR | -20 to 110 | -75+/-3 | Water, Oil, Acid etc. |

| EPDM | -30 to 150 | 80+/-5 | Steam, Acid, Glycoletc. |

| NBR-HT | -30 to 160 | 85+/-5 | Mineral Oil, Thermal Oil |

| EPDM-HT | -30 to 180 | 85+/-5 | High Tempearture Water |

| FPM | -55 to 220 | 80+/-5 | High Temperature Oil |

| Brands | Plate heat exchanger models | |||

| Alfa | M3, M6M, M10M, M10B, M15M, M15B, M20M(T20M) , T20B, T20P, M30, AK20, CLIP3, CLIP6, CLIP8, CLIP10, MX25B, MX25M, TS6M, TS20M, P16, 22/P26, TL6B, TL10B, TL10P, TL15B, A15B, M6MW, M10BW, MK15BW, T20MW, AM10, AM20, A20B, AX30B, AC400, AC600 | |||

| APV | T4, SR1, SR2, SR3, H12, H17, N25, N35, Q030D, Q030E, Q055D, Q055E, Q080E, SR6GL, K34, K55, A055, A085, J060, J092, J107, M60, M92, M107, B063, B110, B134, R5, SR9, Q series, J series, A series, H17, 35 series | |||

| GEA | VT04, VT10, VT20, VT20P, VT40, VT40M, VT80, VT80M, N40, VT405P, NT50T, NT50M,NT50X, NT100T, NT100M, NT100X, NT150S, NT150L, NT250S, NT250M, NT250L, NT350S, FA184 | |||

| Tranter | GC8 GX26 GC51 GX64 GX145 GL13 GX42 GX51 GX85 GL16 *** 044 GC60 GX91 GC26 *** 054 GX 60 GX100 | |||

| Sondex | S4A, S7A, S8A, S9A, S14A, S17, S18, S19A, S20A, S21, S21A, S22, S31A, S37, S38, S41A, S41, S42, S43, S47, S47A, S58, S62, S63, S64, S65, S81, S86, S100, S121, SW40, SF123 | |||

| Vicarb | V8, V13, V20, V28, V45, V60, V85, V110 | |||

| SWEP | C8, GX12, GL13, GC16, GX26, GC26, GX42, GC51, GX51, GC60, GX60, GX64, GX85, GX91, GX100, GX145, GX180, GX series | |||

| FUNKE | FP04, FP08, FP09, FP10, FP14, FP16, FP19, FP20, FP22, FP205, FP31, FP40, FP41, FP50, FP60, FP80, FP81, FP100, FP120, FP405 | |||

| Thermowave | TL90SS, TL90PP, TL150SS, TL150PP, TL250SS, TL250PP, TL400SS, TL400PP, TL500SS, TL500PP, TL650SS, TL650PP | |||

| API | SIGMA25, SIGMA26, SIGMA35, SIGMA35X, SIGMA37, SIGMA56, SIGMA66, SIGMA96, SIGMA106, SIGMA156 | |||

| Propellent Plate Heat Exchanger | |

| Plate Type | Single plate |

| Flow Channel Between Plates | 3.5mm ~12.0mm (Optional depends on working condition) |

| Plate Thickness | 0.4mm ~ 1.0mm |

| Heat Transfer Plate Material | Stainless steel - 304/304L, 316/316L, 254 SMO, Titanium, Hastelloy C-276, others |

| Gasket Material | NBR, EPDM, HNBR, HEPDM, NBR-HT, FKM |

| Pressure Plate Material | Carbon steel, stainless steel and others on request |

| Temperature Range | -50 ~ +180 Varies with the media and gasket selection. |

| Maximum Pressure | Maximum standard pressure 10 bar / 16 bar |

| Port Connection | DN32, DN50, DN80, DN125, DN150, DN200, DN250, DN350 |

A: Our company has been on Heat Exchanger field for 16 years, longer than most suppliers. We've been golden suppliers for years and have authority certificates like CE, ISO9001, and MIC onsite check certificate.

Q: Are there any discounts for the plates for the heat exchangers?

A: Yes. Bigger quantities will enjoy lower discounts!

Q: What information is needed if I want a quotation?

A: Please tell us the type of plate, application medium, or advise the type of heat exchangers, Material, Heat Exchanger Capacity, Heat Transfer Area, Liquid Flow and Temperature in and out, quantity, or any size requirements.

Q: What is the MOQ?

A: We accept loose quantity orders, mixed orders, and any trial orders.

Q: When can I get the price?

A: We usually quote within 2 hours after receiving your inquiry. If urgent, please call or email us to prioritize your inquiry.

Q: How to test the quality of your product?

A: Samples are available for quality tests, or visit our factory to learn more about our products.

Q: Is there after-sales service for your products?

A: Yes. If any problem about the product, please feel free to contact us at any time.

>> Machine Manufacture Plastic Pallet Close Head 220L Oil Drums Blowing Machinery Plastic Drums Barrels Making Machinery

>> High Quality V Groove Ugroove Waterproof Wooden Flooring 8mm 10mm 12mm AC3 AC4 AC5 MDF HDF Vinyl Plank Flooring Spc Floor Lvt Floor Wood Piso Laminate Flooring

>> Portable Rechargeable 3D Face Roller EMS Lifting Device Facial Slimming Contouring Beauty Massage Targeted Sports Entertainment

>> Double 36 Carriers Decker Wire Braiding Machine / Stainless Steel Wire Braiding Machine for Flexible Metal Hose

>> 12kv, 24kv, 36kv 10ka Polymeric Metal Oxide Lightning Arrester/Surge Arrester

>> Injection Molded Scooter Parts Motorbike Motorcycle Plastic Mold

>> Premium Durable HDPE Composite Pipe with Steel Reinforcement

>> CM series Micron Coating Digital Thickness Meter Coating Material

>> Poultry Farming Layer Broiler Chicken Deep Litter System with Nipple Drinker & Feeding Line

>> Factory Supply Agriculture Machinery Tractor Mounted Scraper Land Grader Pto Satellite Land Leveler

>> Plastic PVC Pulverizer/Plastic PVC Grinding Machine for Recycling

>> Power Value Small Size Single Phase 220V 2000W 2000 Watt 2kw 2.2kw Portable Fuel Petrol Gasoline Engine Power Kick Start Generators in China

>> Builders best new apartment bedroom solid hardwood luxury interior doors prices hotel wood door

>> High-Quality Eyh Equipment Series Two 2D Dimension Mixer

>> Home 2 Head Latest Automatic Computer 3D Cap Computerized Embroidery Machine for Price

>> Industrial straw crusher chaff cutter grass chopper for animal feed

>> Factory Manufacturer Lab Scale Carding Machine for Hemp

>> Trampoline Manufacturers for home indoor /Indoor Jumping Gymnastic Fitness Trampoline

>> Gymnastics Trampoline Parks Kids Mini Commercial Trampoline Parks for Sale

>> Automatic Metal Surface Grinding Machine Sg2550ahd CNC Surface Grinding Machine

>> High Precision Drill Press 13mm 5speed Drilling Machine for Woodworking

>> 1224 Carpenter Plywood Cutting Atc CNC Milling Machine with Syntec Controller

>> TRICONEX 4351B brand new in stock with one year warranty at@mooreplc.com contact Mac for the best price

>> 3&4mm Bevelled Edges Bornze Mirror Frosted Glass Switch Panel

>> Stable Absorbable Korea Barbed 4D Cog W Blunt Pcl Pdo Thread for Cheek Lifting Body Tightening

>> Seamless Steel Pipe to Produce Bearing 100cr6 Gcr15

>> Removable Manual Rasierer Reusable Scheermes Beard Shaving Facial Razor For Women

>> Ruijp Good Quality Custom Service Wave Wheel Drum Parts Plastic Washing Machine Moulds

>> Diamond Wire Saw for Concrete

>> Engine Timing Chain Kit ME203085 ME203100 ME204369 for MITSUBISHI TK8030-4