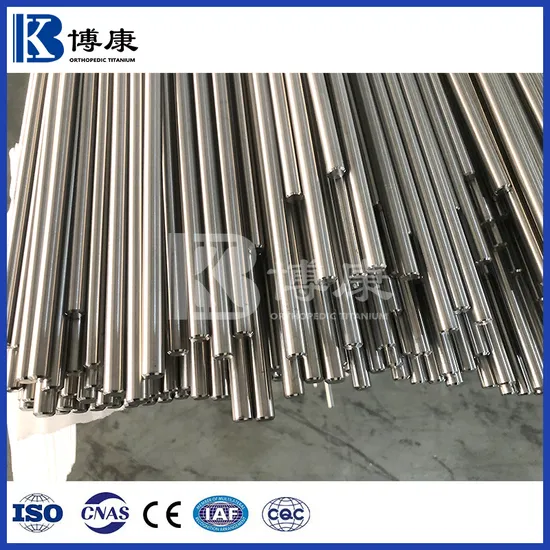

Medical Titanium Bar Material ASTM F67 Medical Implants Grade 2 Pure Titanium

| US$14.00-40.00 | 1 kg (MOQ) |

Basic Info.

Model NO.

BKTR-M

Technique

Hot Rolled, Hot Rolled

Grade

Gr1,Gr2,Gr3,Gr4,Gr5,Gr9,Gr23, Gr1, Gr2, Gr3, Gr4, Gr5, Gr9, Gr23

Shape

Round, Round

Standard

ASTM, ISO, AMS, JIS, DIN

Tolerance

H6, H7, H8, H9

Condition

Annealed (M), Cold Rolled(Y), Hot Rolled(R)

Surface

Bright

Material

Pure Titanium and Titanium Alloy

Length

500-4000mm

MOQ

1kg

Sample

Available

ODM & OEM

Acceptable

Transport Package

Wooden Case

Specification

1.0~101.6mm

Trademark

Bokang

Origin

Changzhou, China

HS Code

8108901090

Production Capacity

200tons/Year

Product Description

Product Description Titanium rods are categorized into pure titanium rods and titanium alloy rods, for pure titanium rods, we mainly offer titanium rods of grades Gr1, Gr2, Gr3, Gr4, etc. For titanium alloy rods, we offer titanium alloy rods of grades Gr5, Gr9, Gr23 and so on.We offer titanium rods in a variety of grades and sizes for several industries, including medical titanium rods (orthopedic, dental, medical devices), aerospace (fasteners, profiles, forgings), and industrial titanium rods.

With a full process production line including melting, all titanium rods can be customized and Bokang is certified to ISO 13485:2016, ISO 9001 and ISO/IEC 17025:2017 for medical use, and our products comply with ASTM, ISO, AMS, ASM, JIS, DIN and other standards.

Titanium Bar Specifications

| Grade | Gr1,Gr2,Gr3,Gr4,Gr5(Ti-6Al-4V),Gr9(Ti-3Al-2.5V),Gr23(Ti-6Al-4V ELI), etc |

| Standard | ASTM F67;ASTM F136; ISO5832-2;ISO5832-3;AMS4928;AMS4965;AMS4967;ASTM B348; ASTM B863 |

| Diameter(mm) | 1.0~101.6mm |

| Length(mm) | 500-4000 |

| Tolerance | h6,h7,h8,h9 |

| Shape | Round |

| Condition | Annealed (M), Cold rolled(Y), Hot rolled(R) |

| Surface | Bright Surface |

Titanium Rod Features:

High Surface Finish

Good Roundness

Small Tolerances

High Dimensional Consistency

Stable Performance

Uniform Composition

Fine Grain Organization

Excellent Overall Performance

Long Fatigue Life

Titanium Rod Production Process:

Sponge Titanium→Compacting Electrodes→Electrode Welding→Triple VAR Melting→Machining→Forging Billet→UT testing→Rolling Billet→Online Straightening→Centerless Lathe→UT testing→Rolling→Metallographic Inspection→Wire Drawing→Precision Straightening→Heat Treatment→Mechanical test→Microstructure test→Centerless Grinder→Eddy Current Test→Polishing→Visual and dimension inspection→Product Marking→Packaging→Delivery

Applications of Titanium Rods:

Titanium rods are widely used in the medical field. They are Used in the manufacture of orthopedic implants (e.g., hip and knee replacements), dental implants, ultrasonic scalpels, surgical staplers, and other surgical instruments.

Chemical Composition Chemical Composition

ASTM F67 Chemical Requirements:

| Element | Composition,% (mass/mass) | |||

| Grade 1 UNS R50250 | Grade 2 UNS R50400 | Grade 3 UNS R50550 | Grade 4 UNS R50700 | |

| Nitrogen, max | 0.03 | 0.03 | 0.05 | 0.05 |

| Carbon, max | 0.08 | 0.08 | 0.08 | 0.08 |

| Hydrogen, max | 0.015 | 0.015 | 0.015 | 0.015 |

| Iron, max | 0.2 | 0.3 | 0.3 | 0.5 |

| Oxygen, max | 0.18 | 0.25 | 0.35 | 0.4 |

| Titanium | balance | balance | balance | balance |

Analysis Tolerances

ASTM F67 Analysis Tolerances:

| Element | Limit or Maximum of Specified Range %(mass/mass) | Tolerance Under the Minimum or Over the Maximum Limit |

| Nitrogen | ≤0.05 | 0.02 |

| Carbon | 0.10 | 0.02 |

| Hydrogen | ≤0.015 | 0.0020 |

| Iron | ≤0.25 | 0.10 |

| Iron | >0.25 | 0.15 |

| Oxygen | ≤0.20 | 0.02 |

| Oxygen | >0.20 | 0.03 |

Mechanical Properties Mechanical Properties

ASTM F67 Mechanical Requirements: Annealed-Bar, Billet, Forgings, and Other Forms

| Grade | Tensile Strength, min | Yield Strength, A (0.2 % Offset), min | Elongation in 4D, min, % | Reduction of Area, min, %C | |||

| KSI | MPA | KSI | MPA | ||||

| 1 | 35 | 240 | 25 | 170 | 24 | 30 | |

| 2 | 50 | 345 | 40 | 275 | 20 | 30 | |

| 3 | 65 | 450 | 55 | 380 | 18 | 30 | |

| 4 | 80 | 550 | 70 | 483 | 15 | 25 | |

Round Wire Size Tolerances:

ASTM F67 Round Wire Size Tolerances:

| Diameter, in(mm) | Size Variation, in. (mm) | Out of round, in. (mm) |

| 0.125~0.3125(3.18~7.94) | ±0.002(0.051) | 0.002(0.051) |

Product Category

| Titanium Bar/Rod | Titanium Wire | Titanium Disc |

| Titanium Ingot | Nitinol/Nickel Titanium | Artificial Joint Castings |

Certifications

About Bokang

Our Advantages

FAQ Q: Are you a direct manufacturer or trading company?

A: We're a manufacturer with more than 18 years of professional production experience.

Q: Do you offer free samples?

A: Usually, our sample is free but we need our customer to pay the freight.

Q: What is the minimum quantity per order?

A: 1 kg. For regular standard medical and aerospace materials, based on our production capacity of 20 tons per month for titanium wire and rods. the stock inventory could meet all your requirements.

Q: What products can you offer?

A: We specialize in the production of pure titanium, titanium alloy, titanium rods, wires, discs, nitinol alloy, etc.,

Q: What's the payment term?

A: When we quote for you, we will confirm with you the way of transaction, FOB, CIF, CNF, etc.

For mass-production goods, you need to pay 30% deposit before producing and 70% balance against a copy of documents. The common way is by T/T. L/C is also acceptable.

Q: What applications do your products relate to?

A: Our titanium alloys and nitinol alloys are widely used in medical, aerospace, and other Industries.

Q: How can we get your price?

A: We need the below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

Q: Can you do customized products?

A: Yes, we support customized products according to the customers' drawings or samples.

Q: How do you guarantee the quality of your goods?

A: We ensure quality by inspecting every process and using advanced testing equipment to conduct comprehensive checks, ensuring finished products meet customer and international standards.

Q: How do you deliver the goods to us?

A: We will usually ship the goods by sea and air according to your requirements.

>> Clear Sweet Candy Jar Honey Plastic Pet Storage Jars for Kitchen Sugar Coffee Candy Snack Plastic Jar

>> Stainless Steel Wire Mesh Conveyor Belt Metal Woven Mesh for Interior and Exterior Design

>> 4 Port Repeater Poe Extender

>> autos front bumper For Ford Mustan GT350 iron Hood Bonnet Engine Covers

>> Chopped Kombu 100g/500g/1kg/2kg

>> Hj/400ba High Speed Injection Blow Molding Production Line

>> VFE Medicai Face Mask Virus Filtration Efficiency Tester

>> High quality Customized Style 170f 173f 178f 186f Farm Tractor Tiller Cultivator

>> Gloffie Streamlined Design for Efficient Lap Swimming Short Swim Fins Flippers

>> Wholesale disposable plastic arm sleeve cover blue PE oversleeve single use oversleeve

>> Custom Antique Street Legal 4+2 Seats Hunting Golf Trolley Electric Lithium Golf Carts

>> Brass Dart with Steel Tip Dart and Pet Dart Flight

>> Hyaluronic Acid Facial Fillers for Youthful Skin and Wrinkle Reduction

>> Cheap 30L 40kg Big Payload Agricultural Spraying Spreading Quadcopter Drone for Agriculture

>> High Efficiency Rubber Vulcanizing Machine/Rubber Product Making Machine/Press Machine

>> In Stock ABB PM150V08 3BSE009598R1 Controller unit MODULE CPU

>> High Quality Long Performance Life Cotton Knitting Gloves Packing Machine

>> 500L 1000 2000 Litre Dark Blue Plastic IBC Tank Bulk Container Manufacturing Extrusion Blow Molding Machine

>> Automatic Stainless steel fish/sausage/meat smoking baking oven

>> Manufactory direct grade best a kernels gansu in shell green walnut good price

>> Heat Setting High Speed Customized Mg Pick up Felt for Paper Mills

>> 0.1L-1L Automatic Rotary Plastic PE PP Bottle Injection Blow Molding Machine/Blowing Machines

>> Disposable Paper Cup Rim Rolling Machine

>> 310V BLDC Standing Wall Pedestal Fan Electric Motor with External Drive Board Low Pressure DC Motor

>> Factory Price Fingerless Vacuum Adsorption Single Facer Corrugated Machine

>> Reliable Conical Twin Screw and Barrel for Pipe Extrusion

>> OEM 971827851 Power Operated Tailgate Lift Support Strut for Porsche Panamera 2017-2020 LH/RH

>> 7.0 Meter PVC/Hypalon Rib Boat/Power Boat/Motor Boat/Speed Boat

>> Aluminum CNC Parts Custom CNC Lathe Aluminum Machining 6082, 6061, 7075

>> Fully Automatic We67K 250t 3200 CNC Press Brake Hydraulic Press Brake Machine