New Design Red Clay Bricks Machine Tunnel Kiln for Modern Bricks Factory

| US$1,000,000.00-3,000,000.00 | 1 Set (MOQ) |

Basic Info.

Certification

ISO9001: 2000, ISO 9001:2008, CE

Customized

Customized

Automatic Grade

Automatic

Type

Concrete Iron Molding Machinery

Cutting Frequency (Time/Min.)

30

Cut Billet Length(mm)

>500

Working Pressure (MPa)

0.6~0.8

Total Power

5.75

Dimensions(mm)

4300×1140×2065

Method

Autoclaved Aerated Concrete

Processing

Brick Production Line

Product

Brick

Brick Raw Material

Concrete

Automation

Automatic

Transport Package

Sea Worth Container

Specification

13000*11000(mm)

Trademark

BRICTEC

Origin

China(Mainland)

HS Code

84749000

Production Capacity

15000-21000(Standard Brick /H)

Product Description

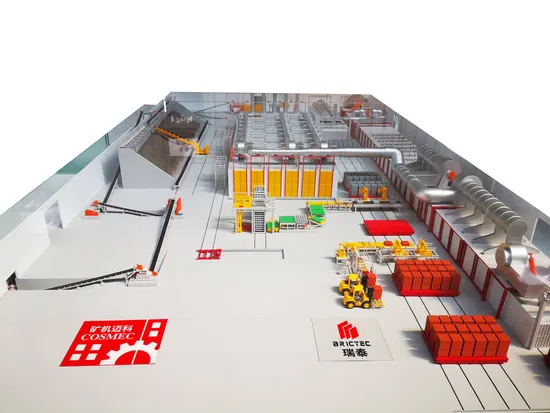

Daily 200 Thousand Pcs clay bricks production line machinery for making red clay bricks

Product Introduction:

It is the largest and most advanced brick production line in Bangladesh. The project adopts advanced two-time loading technology, and the entire brick making process is fully automated to produce high-end sintered products.

The Video of complete production line:

https://youtu.be/3hup-_UxRIs

Basic Information of the project:

| Project | Fully Automatic clay bricks making factory |

| Automatic level | Fully Automatic |

| Production Capacity | 200,000 Pcs/day |

| Bricks to be produced | Solid bricks (254*115*65) |

| 3-holes hollow brick (254*115*65) | |

| 10-holes hollow brick (254*115*65) | |

| Technology | Fully automatic brick machines + Auto-loading& unloading system + rack tunnel dryer + tunnel kiln with auto-coal firing system + auto-packing system |

| Total Investment | 3.5 Million ~5 million usd |

| Total area | 25000 |

| Brick selling price | 12~16 TK (bdt) |

Production Process :

Part 1: Clay Processing Machines & Bricks Shaping Machine:

Doube stage Vaccum Extruder for bricks Shaping

∨

Automatic bricks cutting & Loading system

∨

Rack Tunnel Dryer for bricks Drying

∨

Dried bricks unloading & setting on Kiln car

∨

Tunnel Kiln car loading & Transporting to Tunnel Kiln for Firing

∨

Tunnel Kiln with coal burning system for bricks firing

∨

Fully Automatic Coal feeding & Firing system

∨

Finished bricks packing system

∨

Finished bricks packaging & storage

>> Auto spare part front bumper bracket 52535-0D120 R for Yaris

>> Oval Bread Proofing Basket Linen Liner Cloth Sourdough Rising Basket Baking Gifts for Bakers

>> Large Suction Hose Small Household Grain Pumping Corn Conveying Machine

>> Hy Linear Driver LED GU10 Light for Bedroom

>> Automatic Face Mask Pillow Type Bag Sealing Packing Machine High Speed Wet Tissue Hand Towel Packaging Machines

>> Rotary drum washer minerals sand iron ore washing machine

>> Wholesale Anti Mosquito Retractable Screen Roll Up Metal Window Coverings

>> 1~10 Ton 5m 10m 15m CD MD Type Electric Wire Rope Hoist

>> Warm Knitted Fashion Scarf High Quality Feel Pashmina Scarf

>> High Cost Performance Good Condition Used Plastic Injection Turnover Chair

>> Latex Pillow / Natural Soft Contour Massage Pillow for Home and Hotel

>> Fat Removal 980nm 1470nm Diode Laser Lipolisis Vaser Liposuction Endolaser Lift Machine

>> Integrated Solar Mobile Traffic Light Motor Vehicle Pedestrian Light

>> Servo Control High Speed Automatic Small Soft / Hard Candy Packing Machine

>> Stainless Steel Blades Fiber Optic Anesthesia Laryngoscope Set

>> LED 110V 220V 12W 24W Water Treatment Germicidal Tube Sterilizing Ultraviolet UV Lamp 240nm 250nm 254nm 265nm 275nm UVC Light for Air Sterilization

>> Industrial Electrostatic Powder Supply Center

>> 6 Inch IPS Touch Screen IP67 Waterproof Industrial Handheld Android PDA 4G LTE

>> Direct factory sale nordic study table children tables kids' tables computer desk

>> 15kg side gusset PP woven BOPP Horse Pet Feed Bag with Matt Lamination

>> medical face mask- Manufacturer of disposable medical mask of HAIDIKE from china

>> Computer Controlled Torque Rheometer for Extruder Mixing Unit Applications

>> Clear Self Adhesive Holographic Overlay for ID Card, Easy to Apply and Strong Hold

>> Garment Accessories Crocodile Embroidery Patch and Logo

>> CE Ex1800K Mini Excavator Backhoe Loader Slippage Mini Small Hydraulic Crawler Deisel Excavator for Construction

>> Plastic Milk Shell for Cow Milking

>> China Suzhou Zhangjiagang Plastic Screws Recycling Machine

>> Outdoor Ocean 500d PVC Waterproof Dry Bag with Shoulder Strap, Waterproof Duffel Hiking Dry Bag Backpack 2L 5L 10L 20L 30L Storage Bag

>> 1000 Kg/H Waste Plastic Pet Washing Machine Pet Bottle/ Flake Crushing/ Washing/ Dryer Squeezing/ Recycling Line

>> Black Rivets Pop Rivets Assortment Kit, Assorted Blind Rivets with Case