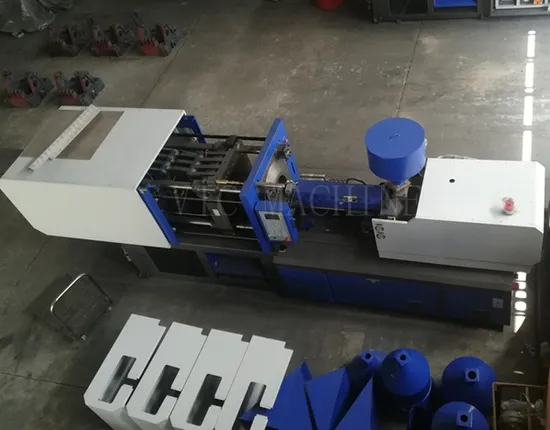

Bottle and cap plastic extruder plastic injection molding machine

| US$32,000.00-50,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

ZSJ

Raw Material

PET

Making Method of Parison

Extrusion-Blow Molding

Automation

semi-automatic

Computerized

Non-Computerized

Certification

CE, ISO9001:2008, QS, GMP

After-sales Service

1 year

English Manual

Yes

Capacity

9 piece one time

Clamping Force

2500KN

Transport Package

Wooden Box

Specification

7.93*1.82*2.24m

Trademark

VIC

Origin

China

Production Capacity

400set/Year

Product Description

Plastic bottle and cap extruder injection molding machine1-body; 2-electromechanical for oil pump; 3-clamping cylinder; 4-firm plate;5-clamping mechanism; 6-pull rod; 7-hooking template; 8-firm board; 9-plasticizing barrel;10 - hopper; 11 - acceleration box; 12 - electric idea;

13 - injection cylinder; 14 - metering assembly; 15 - moving cylinder; 16 - console

Features

The working principle of the injection molding machine is similar to that of the syringe for injection. It is to inject the plasticized molten state (ie, the viscous flow state) into the closed cavity by the thrust of the screw (or plunger). The process of obtaining the product after curing and setting.

Injection molding is a cyclic process, and each cycle mainly includes: quantitative feeding - melt plasticizing - pressure injection - filling mold cooling - mold extraction. After removing the plastic part, the mold is closed again for the next cycle.

Injection molding machine operation items: Injection molding machine operation items include three aspects: control keyboard operation, electrical control system operation and hydraulic system operation. The injection process action, the feeding action, the injection pressure, the injection speed, the selection of the ejection type, the monitoring of the temperature of each section of the barrel, the adjustment of the injection pressure and the back pressure are performed.

Generally, the molding process of the screw type injection molding machine is: firstly, the granular or powdered plastic is added into the barrel, and the plastic is melted by the rotation of the screw and the outer wall of the barrel, and then the machine performs the mold clamping and the injection seat forward. The nozzle is placed close to the gate of the mold, and then the pressure oil is introduced into the injection cylinder to advance the screw, thereby injecting the melt into the lower temperature closed mold at a high pressure and a relatively high speed. Time and pressure are maintained (also known as holding pressure), cooled, and solidified, and the product can be opened by mold opening (the purpose of holding pressure is to prevent backflow of molten material in the cavity, replenish material into the cavity, and ensure the product Has a certain density and dimensional tolerance). The basic requirements for injection molding are plasticization, injection and molding. Plasticization is the premise to achieve and guarantee the quality of molded products, and in order to meet the molding requirements, the injection must ensure sufficient pressure and speed. At the same time, due to the high injection pressure, a correspondingly high pressure is generated in the cavity (the average pressure in the cavity is generally between 20 and 45 MPa), so a sufficient clamping force must be obtained. It can be seen that the injection device and the clamping device are key components of the injection molding machine.

Main data:

| Specification | Unit | ZSJ2400PET | |

| Injection Unit | Screw Diameter | mm | 65 |

| Screw L/D Ratio | L/D | 1:18.5 | |

| Injection Capacity In Theory | cm3 | 830 | |

| Injection Weight | g | 755 | |

| Shot speed | g/s | 242 | |

| Plasticizing capacity | g/s | 34 | |

| Injection Pressure | Mpa | 121 | |

| Screw Speed | rpm | 0-200 | |

| Clamping Unit | Clamping Force | KN | 2400 |

| Toggle Stroke | mm | 480 | |

| Space Between Tie-bars | mm | 520*520 | |

| Max Mould Height | mm | 520 | |

| Min Mould height | mm | 220 | |

| Ejector Stroke | mm | 110 | |

| Hydraulic Ejection | KN | 70 | |

| Others | Max. Pump Pressure | Mpa | 16 |

| Pump Motor Power | kw | 22 | |

| Heater Power | kw | 24.73 | |

| Machine Dimensions (LxWxH) | m | 7.93*1.82*2.24 | |

| Machine Weight | t | 11.5 | |

Component of the injection machine:

| Name | Brand |

| Controller | TAI WAN Techmation 7 color screen |

| Vane pump | America Sunny |

| Main direction valve | America Vickers |

| Proportional valve | Taiwan Dofluid /HNC |

| Hydraulic five star motor | Ttaly Intermot /Zihyd |

| Core puller | One set |

| Linear Transducer | America/France |

| Electric equipment | Japan Omron /Fuji |

| Lubrication | Automatic |

| Main airproof element | Taiwan /Japan |

| Electric motor | Bei jing /zhong da |

More pictures

Production line diagram

Bottle mould

Cap mould

Package

Factory view

Certification

>> Energy Saving Used Plastic Recycling Machine Pet Washing Line

>> Washing Machine Plastic Parts Making Machine Injection Molding Machine Supplier

>> Bread Machinery Bread Kneader Rolling Machine Dough Processing Commercial Dough Divider Machine

>> Biobase Low Temperature Available Efficient Automatic Commercial Air Dehumidifier

>> 8-Disc Nas Storage Server Sas/Nvme Hot-Swappable Chassis

>> Factory Wholesale 3 Rows 15mm Vvs Moissanite Ice out Mens Miami Cuban Link Chain Necklace 925 Sterling Silver Necklace Hip Hop Jewelry

>> 2024 Hot Sale 1000W 1500W 2000W 3000W Laser Automatic Continuous Fiber Laser Welding Machine, Portable Laser Welding Machine

>> Hybrid CNC Bending Machine for Metal Steel/ Ss/ Aluminum/ Copper

>> Custom Metal Stamping Die Tool High-Quality Progressive Punching Press

>> Big Sizes Factory Price Matt Porcelain Floor and Ceramic Wall Tile for Project

>> High Flow Battery Operated Motor Water Sprayer Pump Electrical Micro Irrigation Double 12VDC Diaphragm Pumps

>> Black Leather Men Safety Shoes Man Construction Safety Work Boots

>> Intelligent Multifunctional Rechargeable UVC Hot Wind Drying IP65 Toothbrush Sterilizer in The Bathroom

>> 300W/384wh Solar Generator Portable Power Station Mobile Power Station for Outdoor

>> OEM ODM Whosale Plush Baby Wooden Rocking Chair Kids Children Ride Toy

>> Hot Sale China Plastic Urban Seat Blow Moulding Machine

>> Construction Custom Dump Trucks Soil Cleaning Buy Dump Truck

>> Double-Layer Roof Tile Cold Roll Forming Machine

>> The Best Price for High Quality 50-200mm, 10-80mm Ferro Chrome

>> Kitchen Utensil Set with Gift Bag Exotic Pakkawood 6-Piece Kitchen spoon set

>> Electric Sea Salt Collecting and Crushing Machine Iodine Salt Harvester Machine with Tractor

>> Factory Year-End Hot Sale Fiber Laser Cutting Engraving Machine for Iron Steel Metal Sheet Plate with Good Quality Price

>> Therm 105 Celsius-600 Heat-Resistant PVC Control Cable 300/500V

>> Steel Roofing Sheet Roll Forming Machine Double Layer Metal Roof Machinery

>> 3015 4020 6020 / 1000 Watt 1500 Watt 2000 Watt 3000 Watt / CNC Affordable Laser Cutter (With Separate Cabinet) Price/ Best Choice for Bussiness Beginner

>> 21V Brushless Lithium Electric Impact Wrench, Bare Metal Weight 1.13kg

>> 2023 New Mini Electric Car Golf Buggy Electric Golf Car

>> Automatic High Production Weighing Down Jacket Filling Machine with Double Pipes and Eight Scales(R2-8

>> Portable Handheld Metal Rust Removal Fiber 1000W 1500W 2000W Laser Cleaning Machine Laser Rust Removal

>> Quality Aluminum Adjustable Lamp Angle 5W 7W 12W 15W 25W COB Trunk Gimbal Ceiling Spotlights Elephant Cylinder Downlights