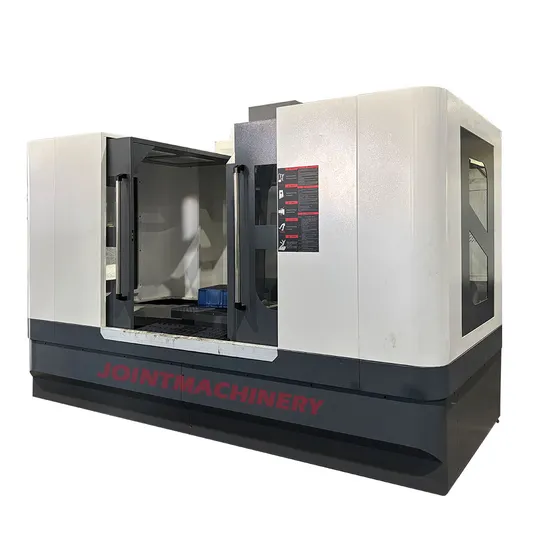

Gun Metal Drilling Machine 3-Axis CNC Deep Hole Drilling Machine for Mould Industry

| US$32,000.00-60,000.00 | 1 set (MOQ) |

Basic Info.

Model NO.

DH-1300

Structure

Deep Hole Drilling

Layout

Horizontal

Controlling Mode

CNC

Number of Shaft

3

Hole Diameter

<50mm

Automatic Grade

Automatic

Precision

High Precision

Certification

CE, ISO 9001

Condition

New

Inner Diameter of Drilling

2.5-30mm

Max Depth of Drilling

1300mm

Table Size

1400*900mm

X Axis Travel

1300mm

Y Axis Travel

1000mm

Z Axis Travel

1300mm

Cutting Feeding

1-300mm/Min

Max Rotary Speed of Spindle

7000rpm

Spindle Motor

7.5/11kw

Three Axis Motor

3/3/2.3kw

Pressure of Oil Pump

0-150kg/Cm

Capacity of Cutting Tank

800L

Max Load Weight of Table

10000kg

Weight

12000kg

Demension

4800*3800*2800mm

Transport Package

Wooden Pallet and Wooden Case

Specification

4800*3800*2800mm

Trademark

JOINT MACHINERY

Origin

China

HS Code

8459210000

Production Capacity

300

Product Description

In the realm of machining operations, drilling holds the esteemed position as a foundational technique that plays an indispensable role across numerous applications. Historically, traditional drilling machinery, including bench drills, milling machines, and radial drills, have relied heavily on manual intervention, relegating workers to monotonous tasks with constrained quality control. This has naturally led to challenges in maintaining safety, optimizing efficiency, and overcoming processing limitations for both manufacturers and operators. Enter the era of CNC technology, with its groundbreaking CNC deep hole drill, which has dramatically altered this landscape. This innovation liberates laborers from manual duties and effectively addresses the constraints of deep drilling. By facilitating single-pass drilling that rivals the quality of traditional machines, alongside performing reaming and expansion tasks, this advanced technology also automates chip removal, CNC positioning, and precision processing. The result is a redefinition of efficiency and a significant enhancement in product quality outputs.

| 3 Axis CNC Deep Hole Drilling Machine | 4 Axis Vertical CNC Deep Hole Drilling Machine | Multi-Spindle CNC Deep Hole Drilling Machine | 6 Axis CNC Deep Hole Drilling Machine |

Crafted with meticulous precision, the CNC deep hole drilling machine is engineered to meet the demanding needs of diverse workpieces that require intensive deep hole drilling processes:

√ Die & Mould Industry: Optimally engineered for complex tasks such as crafting water transport holes, center holes, hot runners, guide roller holes, and beyond.

√ Auto Industry: Exceptionally suited for intricate deep hole operations in components like cylinder heads, crankshafts, hydraulic tubing, plunger bushings, and more.

√ Oil Pump & Lubricating Nipple Industry: Masterfully designed for precision deep hole drilling in oil-injection gases, nozzle valves, plunger bushings, and a vast array of critical spare parts.

√ Textile Machinery Industry: Enables seamless precision mesopore drilling across a variety of spindles.

√ Medical Equipment Industry: Specializes in high-precision axial processing on materials such as titanium alloys and stainless steel, adhering to stringent medical standards.

√ Mining & Oil Machinery: Provides formidable solutions for robust deep hole processing on piston rods and cylinder walls, catering to heavy-duty requirements.

√ Electrical Power & Steam Turbine Industry: Excels in the intricate processing of deep holes in rotors, central spindles, valve spindles, unit outer cylinders, and condenser tube plates.

Gun Metal Drilling Machine 3-Axis CNC Deep Hole Drilling Machine for Mould Industry

| Model | Unit | DH-1300 |

| Inner diameter of drilling | mm | 2.5-30 |

| Max depth of drilling | mm | 1300 |

| Table size | mm | 1400*900 |

| X axis travel | mm | 1300 |

| Y axis travel | mm | 1000 |

| Z axis travel | mm | 1300 |

| Cutting feeding | mm/min | 1-300 |

| Max rotary speed of spindle | rpm | 7000 |

| Spindle motor | kw | 7.5/11 |

| Three axis motor | kw | 3/3/2.3 |

| Pressure of oil pump | kg/cm | 0-150 |

| Capacity of cutting tank | L | 800 |

| Max load weight of table | kg | 10000 |

| Weight | kg | 12000 |

| Dimension | mm | 4800*3800*2800 |

Shenzhen Joint Machinery Co., Ltd. is a paragon of excellence in the manufacturing and exporting industry, specializing in CNC lathe machines, CNC deep hole drilling machines, Swiss-type automatic lathes, milling machines, grinding machines, and beyond. Our unwavering dedication to unmatched quality and service forms the bedrock of our operations, ensuring that every machine achieves the highest industry standards. By integrating pioneering technologies from Taiwan and Germany, we harness state-of-the-art equipment that delivers machines celebrated for their unparalleled precision, stability, and reliability. Designed to accommodate the most complex and high-demand machining needs, our products have earned international recognition and cultivated a devoted customer base across Asia, Europe, South America, and North America. Through steadfast partnerships with clients worldwide, we generate significant business value and collaboratively shape the future of the industry.

https://jointcncmachinery.en.made-in-china.com/product-group/RbcTBhYuqItx/3-Axis-CNC-Deep-Hole-Drilling-Machine-1.html?pv_id=1ikc46nb1bdd&faw_id=1ikc46pvq3eb

https://jointcncmachinery.en.made-in-china.com/product-group/foIGDlkuaHaj/4-Axis-Vertical-CNC-Deep-Hole-Drilling-Machine-1.html?pv_id=1ikc46qkf3bb&faw_id=1ikc4743q5c3

https://jointcncmachinery.en.made-in-china.com/product-group/PbcaQBzMhIAO/Multi-Spindle-Deep-Hole-Drilling-Machine-1.html?pv_id=1ikc474pm20f&faw_id=1ikc47h7sa4f

Unveiling the Excellence: Discover the Exceptional Multi-Spindle Deep Hole Drilling Machine by Shenzhen Joint Machinery Co., Ltd.! Explore more about our state-of-the-art technology and high-performance solutions at: https://jointcncmachinery.en.made-in-china.com/product-group/PbcaQBzMhIAO/Multi-Spindle-Deep-Hole-Drilling-Machine-1.html?pv_id=1ikc4anub788&faw_id=1ikc4bbdd030

2ecf8322

>> Stainless Steel Pipe Making Machine / Ss Tube Mill Sold to Hisar City in India

>> Syochi Sports Recovery 0 Degrees Ice Bath Chiller and Heater 1HP

>> Diving Decompression Chamber Hyperbaric Oxygen Chamber Price

>> Nai-Lok Alloy Hc276 Sampling System Double End 1/4 1 2 Female NPT 1800psi 1000ml 500ml Seamless Steel Gas Sample Cylinder for LPG LNG

>> High Speed Metal Manual Pedal Shearing Machine

>> Whgcm 10L Titanium Hastelloy Autoclave High Pressure Lab Reactor with Jacket Heating for Chemical Research

>> Bright Yellow Powder Organic Dye High Quality Industrial Grade Optical Brightener for Wires

>> Fishmeal Machine Tricanter Three Phase Separation (Xinzhou Brand)

>> 30 Tons Used Good Condition Sy305 Sy365 Excavator Second-Hand Excavator in Stock

>> High quality TNC male crimp for RG6 connector

>> Haolin Electric Leisure Tricycle, Fashion and Leisure China

>> PVC Auto Weighing Mixing and Feeding System

>> 1575-6000mm Fourdrinier Writing & Printing Paper Machine

>> High Efficient Da66t 100t 3200mm Steel Bending Machine

>> health scanner machine

>> Precision Cw61100 Heavy Duty Lathe – Reliable Horizontal Machining Solution

>> 3BHB017688R0001

>> 316L Stainless Steel RF Blank/Blind Flange DN100 4 Inch Class 150 A105 Steel Slip on Flange Awwac207

>> High Borosilicate Glass Test Culture Tube Borosilicate Glass Tube

>> Railway Freight Agent Shipping Container Pakistan Price LCL FCL

>> One-Way Servo Pump CNC Press Brake Bending Machine Pbc-160t/4100mm

>> Zx45V Small Gear Drive Senmo Mini Drilling Milling Machine

>> TEM82E Magnetic Flow Meters Magnetic Type Flow Meter Flowmeter Measurement Apparatus

>> Children′ S Double Wear Sherpa Fleece Lined Coat and Jackets

>> Automatic Folding Elektrorollstuhl with Brush Motor Power Lightweight Wheelchair for Elderly

>> 7-Inch WiFi Photo Album Frameo Software Touch Screen Smart Digital Photo Frame

>> White Zinc Plated High Quality Hexagon Bolts DIN7991 Hex Socket Flat Head Screw Countersunk Head Screw Alloy Steel Grade 10.9

>> VMIVME-2536

>> A4 Picture Frame Set Modern Luxury Wall Mount or Tabletop Display Black Plastic A4 Certificate Frame

>> 58kHz Am Dual Antenna Alarm Gate Supermarket Shopping Mall Clothing Store Use