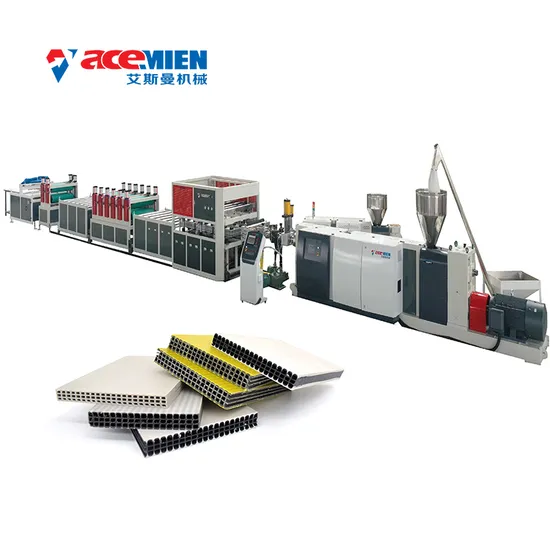

PP Plastic Hollow Construction Building Template Formwork Sheet Making Machine Extrusion Line

| US$178,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

ASM-H-08

Product Type

PP Board

Board Layers

Multilayer

Screw No.

Single-screw

Automation

Automatic

Computerized

Computerized

Certification

CE

Customized

Customized

Condition

New

Color

Customers Requirment

Transport Package

Wood Case with Plastic Film

Specification

40*15*18m

Trademark

ACEMIEN

Origin

China

HS Code

84778000

Production Capacity

>1000pieces/a Year

Product Description

Product DescriptionPP Hollow Construction Formwork Production Line

The production line can use PP raw materials and adopt a single-screw extruder to produce three-layers hollow sheets. The quality and specifications of the produced plates meet the requirements of the demanding company.

The extrusion machine mainly consists of feeding system, main extruder, extruder vacuum system, screen changer, metering pump, extrusion die, vacuum setting die, water circulation cooling system, setting table vacuuming system, cooling bracket, Traction machine, longitudinal trimming machine, horizontal cutting machine, stacking table, electrical control system, etc.

PP Hollow Construction Formwork Advantages:

1. Light weight, high strength, high hardness, impact resistance, wear resistance.

2. Surface is smooth, bright and clean; Concreting and forming effect is good for pp hollow sheet making machine.

3. No absorption of moisture, no deformation, no mildew; Long-term immersion stratification in the water, no bubbles, sheet size stability, especially suitable for underground and damp environment.

4. Good toughness. pp hollow sheet making machine could be used as cambered special-shaped formwork.

5. Acid and alkali resistance, corrosion resistance; pp hollow sheet making machine is very suitable for the engineering application in coastal areas, mine, as well as seawall. pp hollow sheet making machine needs not do any preservative treatment both in using and storing the formwork, which do not pollute the concrete surface.

6. The reusable time for pp hollow sheet making machine can reach more than 60 times, long service life.

7. Waste products can be recycled and reprocessed, making full use of waste materials. This property can greatly reduce the project cost compared with wooden formwork and bamboo formwork.

8. Environmental protection and energy saving, no pollution. No any poisonous or harmful gas.

9. Demould easily. No need brushing release agent, only tapping, the plywood formwork price will fall off. Shorten working hours and speed up the construction schedule efficiently.

10. Easy to process. Sawing, drilling and nailing are all available. pp hollow sheet making machine can be combined vertically and horizontally optionally.

11. Easy to remove. Removing is convenient, quick and safe, and the supporting is also easy to operate, advantageous to the organization construction, effectively improving the construction schedule.

Machine list:

| No. | Machine | Qty. |

| 1 | Screw loader | 1set |

| 2 | ASM110/35 single screw extruder | 1set |

| 3 | Screen changer | 1set |

| 4 | Metering pump | 1set |

| 5 | Extrusion mould | 1set |

| 6 | Calibration mould | 1set |

| 7 | Mould shelf | 1set |

| 8 | Vacuum calibration table | 1set (3 groups) |

| 9 | Mold temperature controller | 1set |

| 10 | Vacuum system | 1set |

| 11 | Chiller | 1set |

| 12 | Haul-off unit with 6 rollers (Forward) | 1set |

| 13 | Trimming device | 1set |

| 14 | Haul-off unit with 2 rollers (Backward) | 1set |

| 15 | Cutter | 1set |

| 16 | Belt conveyor | 1set |

| 17 | Electrical control system | 1set |

Work Condition (provide by customer)

| Temperature & Humidity | ≤40ºC, ≤95% |

| Power supply | 3-phase, 380 V, 50 Hz(or customized) |

| Wire/cables: | Wires/cables from power supply to control cabinet of this production line; |

| Cooling Water hose/pipe | Water supply to machines and pools |

| Lubrication oil: | Sinopec, Exxon mobile |

Energy Consumption

| Installation power | Total 250Kw, Actual consumption about 130Kw |

| Cooling Water | 5M3 / h; 20ºC |

| Compressed air | 1M3 / h, 0.5-0.7Mpa |

| Manpower | 3 Persons/shift(24 hours need 2-3 shifts) |

Acemien Service 1. Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract. We promise that the products of this line could storage for one year without adding any aseptic.

4. After sales

After checking, we offer 12 months as quality guarantee, free offer main parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.

FAQ

Q1: Do you have reference project?

A1: We have reference project in most countries, If we get the permission of the customer who has brought the machines from us ,we can tell you their contact information, you can go to visit their factory.

And you are always welcome to come to visit our company, and see the machine running in our factory, we can pick you up from the station near our city.

Contact our sales people you can get video of our reference running machine

Q2: Do you provide customized service?

A2: We can design the machines according your requirements(material ,power, product type, machine color and so on),at the same time we will give you our professional suggestion, as you know, we have been in this industry for many years.

Q3: What's your guarantee or the warranty of the quality if we buy your machines?

A3: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q4: How long time for installation?

A4: According to your machines order, we will send one or two engineers to your plant, it will take about 10 days to 25 days.

>> OEM New S19 Control Board for L7 E9 PRO Ka3 Main Board Mother Boards

>> Offroad Heavy Duty Spare Tire Garbage Bag for Overlanding Accessories SUV Trunk Organizer Cargo Tool Storage Bag

>> Plastic Crushing Machine Shredder Blade Box

>> Drop-on Application Glass Beads Used on Road Marking Reflective BS6088 Standard

>> High Tech IGBT Infineon IGBT Transistor

>> 600X600mm 24X24 Antistatic Steel False Raised Access Flooring for Data Center

>> Industrial 3D Food Lab Powder Mixing System

>> Wholesale Anthocyanidins 25% Proanthocyanidins Powder Black Currant Extract

>> Modern Dining Room Beige Fabric Gold Restaurant Chair

>> High-quality hydrogen generator

>> Zs-19-004s Handheld Megaphone Amplifier 240 Second Recording High-Power Loud-Speaker

>> Secondhand Mitsubishi Fuso 10m3 Concrete Mixer Hjc6a Used High Quality with Nice Price

>> Hydraulic Iron Worker, Hydraulic Combined Punching and Shearing Machine, Hydraulic Ironworker

>> Insulating Glass Production Line Argon Gas Window Filling Gas Machine

>> Injection Molding Machine Digital Signal Output Module

>> Small Mini Bench Table Metal Drill Press ( Drilling Machine ZQ4113 ZQ4116 ZQ4119 ZQ4132)

>> New Arrival Significant Economic Benefits Upgrade Product Fully Automatic Face Masking Machine

>> Industrial Mine Belt Conveyor For Conveying Grind Mineral Ores Crushed Rocks Sugar Salt Cement Fertilizers

>> Electric Mosquito Repellent Liquid Mosquito Repellent Hot Sale Pollution-Free Electric Mosquito Repellent Liquid

>> Outdoor Camping Beach Folding Bed Simple Siesta Office Siesta Escort Portable Marching Bed

>> Co-Extruded WPC Decking Outdoor 23*138mm

>> Mini External Battery 10000mAh Portable Super Fast Charger Powerbank with Digital Display

>> 1.7m/1.9m Height Door Frame Mobile Walk Through Ladders H Frame Scaffold

>> Disposable Laparoscopic Trocars with ISO CE Surgical Instrument

>> Iron Casting Material Low Carbon Ferrochrome/Ferrochrome Lumps

>> Hot Sale Saurer Machine Quilting Machine Spare Paers Plastic Shuttle

>> UT9060 Maquina de Revelado de Polimero flexo plate making machine

>> Chicken Farm Poultry Plastic Transportation Cages

>> Acne Scar Treatment RF Fractional Microneedle Wrinkle Removal Machine

>> Hypermax Brushless Impact Screwdriver Electric Driver Cordless Impact Driver