Sm 265/205 Swiss Type CNC Lathe Machining Case or Part

| US$25,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

swiss lathe machine

Type

Multicut Lathe

Processing Accessory

Chuck CNC Lathe

Guide Rail

Horizontal Guide Rail

Tool Holder

Double-tool Holder CNC Lathe

Power Source

Hydraulic Pressure

Controlling Mode

CNC

Automatic Grade

Automatic

Setting Mode

Table

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

System

Fanuc 0I TF-Plus /Syntec 220tb

Max.Rpm

Main8,000min-1/Sub8,000min-1

Main Spindle Stroke

210mm

Rapid Traverse Speed

32m/Min

O.D Tools

5X [16X16]

Back End Tools

4X [20-Er16]

Main Motor

5.5/7.5kw

Sub

1.5/2.2kw

Weight

4,500kg

Size

2760mmx1564mmx1882mm

Transport Package

Standard Packin

Specification

2760mm-1564mm-1882mm

Trademark

Wayne

Origin

China

HS Code

8458110000

Production Capacity

50000/Year

Product Description

Product Description

Step into the realm of precision excellence with our Advanced Swiss CNC Lathe Machine. This state-of-the-art tool embodies the pinnacle of CNC automation technology, transforming your workshop into a hub of advanced operations. From tapping and milling to drilling and turning, each task is performed with astonishing precision. Featuring dual spindles and an innovative double Y-axis, this lathe exemplifies efficiency, allowing for simultaneous processing that dramatically reduces production time. Perfectly designed for batch production of intricate, non-standard components, this machine excels in crafting precision hardware and uniquely shaped shafts with unparalleled expertise.

Product Parameters

| SM205/SM265 | |

| FANUC 0i TF-PLUS | SYNTEC 220TB |

| Main10,000min-1/Sub8,000min-1 | Main8,000min-1/Sub8,000min-1 |

| φ20mm/φ26mm | |

| 260mm | |

| 32m/min(X1:24m/min) | 24m/min |

| 6X [12×12]/5X [16×16] | |

| 5X [φ25-ER16] | |

| 4X [ER16] | |

| 4X [ER16] | |

| 2.2/3.7KW | 3.9KW |

| 1.5/2.2KW | 3.9KW |

| 0.75KW | 0.75KW |

| X1:0.75KW;:0.5KW | 0.75KW |

| 0.4KW | |

| 180L | |

| 1.8L | |

| 1,000mm | |

| 3,600Kg | |

| 2610×1530×1674mm | |

| 7axis/4axis | |

| LCD 10.4" | |

| Standard | |

| Standard | |

| Standard | |

| Standard | |

| Standard | |

Items | ||

| Standard units | Hand wheel | C:0.001° C axis resolution: 0.001 ° |

Floodlight | The product output device | |

Transformer | Centralized lubrication system | |

| Three color light | Synchronus rotary guide bush holder unit | |

| /C+ Main/Sub axis C + brake | Auxiliary shaft workpiece ejection device | |

| M Air blow on Sub spindle | Cooling box | |

| 0ptionanl units | Bar feeder | Rectangular power seat |

Oil cooler | Long after loading device | |

Gun drill | Dynamic seat adjustable Angle | |

Chip conveyor | 4 [ER16] 4axis cross tools (module) | |

Oil mist collector | 2 [ER16] 2axis eccentricity tools(rotating) | |

High pressure pump | After the end of the quick change perspective | |

Thread whirling rings | 3+1 [ER16] Back end tools 3axis (rotating)+ 1 axis (fixed) | |

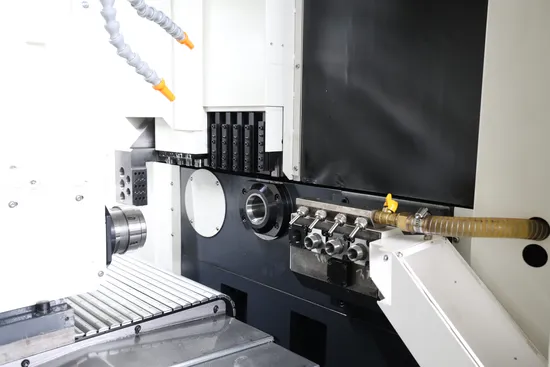

Detailed Photos

Application

Applications of Swiss Machining

Originally conceived for the watchmaking industry, Swiss machining's versatile technology now spans a diverse range of fields. Industries that harness this precision tool include:

1) Aerospace

In the aerospace sector, where the demand for intricate components is overwhelming, Swiss machining rises to the challenge. This industry depends on these lathes to craft critical parts from materials such as aluminum alloys and steel, producing essential items like fans and fasteners.

2) Medical devices

In the medical industry, the Swiss-type lathe is vital for producing delicate, high-precision components. It is fundamental to manufacturing surgical instruments and implants, meeting the exacting precision standards demanded in the field.

3) Electronics

With electronics becoming more compact and sophisticated, traditional lathes often fall short. Enter CNC Swiss machining, providing unmatched capabilities in crafting connectors, pins, and intricate electronic components that align perfectly with the needs of modern technology.

4) Automotive

The ever-evolving automotive industry, with its complex mechanical needs, greatly benefits from Swiss machining technology. It is key in fabricating intricate components that drive the innovation in modern automotive design.

Through Swiss machining, auto manufacturers efficiently produce suspension components, carburetor covers, and engine parts, gaining advantages such as cost reduction, optimized production processes, and heightened manufacturing speed.

Our Advantages

1. Professional Supplier: Trust in our seasoned team of experts, dedicated to providing you with top-tier precision machinery solutions that are precisely tailored to your specific needs.

2. Best Quality: Discover unmatched quality standards that assure reliability and peak performance, highlighting our unwavering commitment to excellence.

3. Best Service: Experience outstanding customer service that prioritizes your satisfaction, ensuring a seamless journey from your initial inquiry to final delivery.

4. Best Price: Take advantage of our competitively priced offerings, crafted to deliver extraordinary value without compromising on quality or service.

Packaging & Shipping

FAQ

1.What products do we have ?

Machine :laser engraving machine ,laser cutting machine ,laser welding machine ,laser marking machine /cnc lathe machine ,swiss type cnc lathe machine ,cnc machine center

2.Why Choose us ?

1)Faster delievery time

2)Full set of production equipment

3)Any third party test can be accepted

4)Payment terms are more flexible ,both TT and LC can be accepted

5)Perfect Pre-sale and After-sale services can be provided within 24 hours online

3.What is the best advantage do we have ?

Best Quality ,Best service ,Best price

>> High Speed Chaoli 48000rpm 24V DC 480 Brushless Motor for Gun

>> Double Countersunk Flat Head Yellow Zinc Chipboard Screw

>> Wholesale Deodorant Sticks Paper Package Box Lip Balm Container Paper Tube

>> HACCP BRC Halal Food Natural Fresh Vegetable Pickled Sushi Ginger for Ukraine

>> Automatic Heave Duty Computer Pattern Sewing Machine for Thick Leather Belt

>> Locor High Quality Single Head Embroidery Machine Industrial Embroidery Machine

>> DIY Painting by Numbers Kits Animal Colorful Artwork Paint of Number Oil Painting

>> Stainless Steel Exchange Platform Cutting Machine/Stainless Steel Exchange Platform Cutting Machine3kw/Stainless Steel Exchange Platform Cutting Machine6kw

>> New 6 Gas Burners Commercial Economy Cooking Gas Range

>> Jiangsu, China Metal-Cutting CNC Tools Efficient Wire Cutting Machine EDM

>> HC-O010 Factory Price Autoclave steam sterlizer 35-100L stainless steel hand round automatic vertical high pressure sterlizer

>> Jcm-1201 800*1200mm Fast Delivery One Head Multi Needle Large Size Embroidery Machine

>> Elegant 23-Inch MDF Bathroom Cabinet Featuring Two Spacious Drawers

>> Ceiling decoration powder coating diamond expanded lath with high quality

>> Vmc1370 3 Axis Vertical CNC Machine Center

>> Alloy Pull Back City Rescue Vehicle for Children Toy Car

>> Taijia Flange ultrasonic flowmeter china ultrasonic flow meter portable

>> unique iron doors/wrought iron door front entry door gates

>> Mindray Used BC-3000 Plus 3 part 19 parameters Blood analyzer machine hematology analyzer Mindray BC 3000 Plus

>> Custom 3ply Print Face Mask Child Use Printed Face Mask For Protection

>> FTTH Eg8247h5 Hg8247h5 Eg8143A5 Xpon Gpon Epon Ont 1ge+3fe+Pots with CATV Port 2.4GHz WiFi

>> LED Decorative Mirrors Wall Mounted Makeup Mirror Cosmetic Vanity Table

>> New Design Foldable Outdoor Rechargeable Electric Cooling Portable Neck Fan

>> deluxe model headlight washer cover for ASV5# 1501-Camry auto part

>> Highly Recommend Nonwoven Wallpaper for Bedroom Decoration

>> 8kw 10kw Solar Power Mounting Hybrid Deye Inverter Power Storage Home System

>> 2022 New Crop High Quality Chinese Fresh Ginger for Sale

>> Agricultural Equipment Sugarcane Cutting Machine Sugar Cane Harvester Harvesting Machinery Exporters

>> TFBA4060 Flat Vacuum Table Manuel Mini Silk Screen Printing Machine

>> Perfect Match for Mobile Plants The Mobile Big Bag Discharging and Bulk Truck Loading System