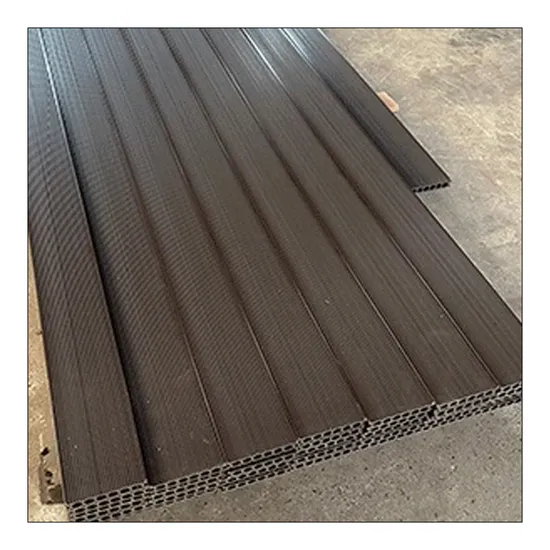

Factory Non Cracking No Warping Outdoor Garden Co-Ex Decking Floor Co-Extrusion Composite WPC Decking

Basic Info.

Model NO.

WD-010

Style

Modern

Environmental Standard

E0

Function

Waterproof, Anti-Static, Thermal Insulation

Certification

CE / ISO

Usage

Household, Outdoor, Commercial, Fireproof

Customized

Customized

Product Name

WPC Decking

Material

Wood-Plastic Composite

Material Component

60% Wood Fiber + 30% HDPE+ 10% Additives

Surface Treatment

Sanding,Brushing,Groove,Wood Grain,Co-Extrusion

Advantage

Eco-Friendly Weather Resistant

Application

Outdoor Construction

Deck Style

Square Hollow / Round Hollow / Solid

Size

2.2m/2.8m/2.9m/3.6m/4m/5.8m/Customized

Transport Package

Bubble Film with Pallet

Trademark

LT

Origin

Zhejiang, China

HS Code

3918909000

Production Capacity

800000m Per Month

Packaging & Delivery

Package Size

250.00cm * 15.00cm * 3.00cm

Package Gross Weight

15.000kg

Product Description

Advanges of Wood Plstic Composite

Natural Wood Texture,High Strength, Clean, Elegance Easy to Work,

Eco-Friendly, Ideal deco material for outdoors Water-proof,

Humidity-proof, Acid Base, Termite ProtectionHigh density,

Resistant,No Rotting, Non-deformation Durable Temperature

between -40 to +60 Centi Degree No Painting,No Glue and Low

Maintainence UV Protection,Stable ColorFully Environmental,

Recyclable, Saving Forest Resource Co-extrusion Decking Covered with a high polymer that completely encapsulates the board in an impermeable layer of protection from fading, staining mildew,and scratching.

created a patented process called Naturalerm on its that makes the board visually more matte and gives a realistic fibrous texture to the board. 3D Wood Grain Decking is a revolutionary products to traditional wPCThe embossing process didn't from "thermo print" but "pressure print" so this wood grain can stay at least 8-10 years.

It keeps plastic crust so the surface is more hard and absorb less water.Scratch will not work on the surface because of the hard surfaccwater/oil/wine stain will not stay on the surface as well Co-Extrusion Decking

Co-extrusion decking foor has solid, hollow 2 big kinds of product, apply to average household respectively

and the business place oferowd dense.In each of the subtle grooves, all the polymer composite protective layer 360 - degree full - covering technology.Ayoid mildew, water cracking, discoloration, deformation and warping defects of traditional solid wood. preservative wood.common outdoor profile and other productsPlastic Wood Co-Extrusion products have solid wood color changes and texture, polymer protective layer 360-degreefull coverage technology.While comprehensively enhancing the product strength.we also ensure that the product can withstand the severe test of outdoor enyironment and avoid various defects of traditionasolid wood and anti-corrosion wood roducts.The rich color sclection of the wholc color system further strengthens itshigh-end status in the field of outdoor foor, so as to adapt to different cultural backgrounds worldwide.develop new products and meet different demands of customers.

| PRODUCT SPECIFICATION | ||||||||||||||||||

| Item | Standard | Requirements | Result | |||||||||||||||

| Slip Resistance Dry | EN 15534-1:2014 Section6.4.2 CEN/TS 15676:2007 | Pendulum value≥36 | Longtitudinal direction:Mean 72,Min 70 Horizontal direction:Mean 79,Min 78 | |||||||||||||||

| EN 15534-4:2014 Section 4.4 | ||||||||||||||||||

| Slip Resistance Wet | EN 15534-1:2014 Section6.4.2 CEN/TS 15676:2007 | Pendulum value≥36 | Longtitudinal direction:Mean 46,Min 44 Horizontal direction:Mean 55,Min 53 | |||||||||||||||

| EN 15534-4:2014 Section 4.4 | ||||||||||||||||||

| Falling mass impact resistance | EN 15534-1:2014 Section7.1.2.1 | None of the speciments shall a failure with a crack length≥10mm or a depth of residual indentation≥0.5mm | Max.Crack length(mm):No crack Max.Residual indenation(mm):0.31 | |||||||||||||||

| EN 15534-4:2014 Section 4.5.1 | ||||||||||||||||||

| Flexural properties | EN15534-1:2014 AnnexA | -F'max:Mean≥3300N,Min≥3000N -Deflection under a load of 500N Mean≤2.0mm,Max≤2.5mm | Bending Strength:27.4 MPa Modulus of elasiticity:3969 MPa Maximum load: Mean 3786N,Min 3540N Deflection at 500N: Mean:0.86mm,Max:0.99mm | |||||||||||||||

| EN 15534-4:2014 Section 4.5.2 | ||||||||||||||||||

| Creep behaviour | EN 15534-1:2014 Section7.4.1 | Known span in use: Mean S≤10mm,Max S≤13mm, Mean Sr≤5mm | Span: 330mm,Mean S 1.65mm,Max S 1.72mm,Mean Sr 1.27mm | |||||||||||||||

| EN 15534-4:2014 Section 4.5.3 | ||||||||||||||||||

| Swelling and water absorption | EN 15534-1:2014 Section8.3.1 | Mean Swelling:≤4% in thickness,≤0.8% in width,≤0.4% in length Max swelling:≤5% in thickness, ≤1.2% in width,≤0.6% in length Water absorption: Mean:≤7%,Max:≤9% | Mean Swelling:1.81% in thickness,0.22% in width,0.36% in length Max Swelling:2.36% in thickness,0.23% in width,0.44% in length Water absorption:Mean:4.32%,Max:5.06% | |||||||||||||||

| EN 15534-4:2014 Section 4.5.5 | ||||||||||||||||||

| Boiling Test | EN 15534-1:2014 Section8.3.3 | Water absorption in weight: Mean≤7%,Max≤9% | Water absorption:Mean:4.32%,Max:5.07% | |||||||||||||||

| EN 15534-4:2014 Section 4.5.5 | ||||||||||||||||||

| Linear thermal expansion coefficient | EN 15534-1:2014 Section9.2 | ≤50×10 K¹ | 34.2 x10 K¹ | |||||||||||||||

| EN 15534-4:2014 Section 4.5.6 ISO 11359-2:1999 | ||||||||||||||||||

| Resistance to indentation | EN 15534-1:2014 Section7.5 | Brinell hardness: 79 MPa Rate of elastic recovery:65% | ||||||||||||||||

| EN 15534-4:2014 Section 4.5.7 | ||||||||||||||||||

| Heat reversion | EN 15534-1:2014 Section9.3 | Test Temperature:100ºC Mean: 0.09% | ||||||||||||||||

| EN 15534-4:2014 Section 4.5.7 EN 479:2018 | ||||||||||||||||||

>> Soybean Combine Harvester with 4kg Feeding Capacity

>> Vegan Protein Fava Bean Protein Powder 90% for Nutritious Foods

>> Indoor Gym Taekwondo EVA Floor Mat

>> Multi Heads Computerized Brother Shirts and Hats Embroidery Machine Price

>> Factory Price Automatic Paper Napkin Tissue Making Machine

>> Feed Processing Machines/Full Automatic Cheap Price Mini Feed Pellet Machine

>> industrial tray dryer fish drying machine fish dehydrator oven

>> 1325 DSP A11 A18 Control System 3 Axis 4axis CNC Carving Wood Rotary Machine with CNC Router Rotating Axis

>> Durable Pelham Bit for Optimal Riding Experience and Precision

>> Easy to Maintain Durable Bearings Mining Box Hammer Crusher

>> 2022 Innovative Daisy Player Connect with Internet Daisy Player for Blind

>> Advanced 341L High Column Sewing Machine with Automatic Oil Supply

>> Real Crocodile Leather Wallet Short Leather Multi-Card Card Holder New Leather Wallet Buckle Wallet Unisex

>> TV Stick, TV Stick Supported Android 7.1, 2.4GHz/5g TV Stick

>> Plastic Machinery 160 Tons Automotive Interior Parts Manufacturing Haitian Injection Molding Machine

>> Animal Husbandry Equipment Cattle Brush for Cattle Bady Cleaning

>> Demark Automatic Accurate Soda Pop Drinks Blowing Filling Capping Machine

>> Manual Ferrule Crimping Machine Machine Crimping

>> Gantry Type Milling Machine Plano Milling Machine

>> Wedding Bounce House with Inflatable White Bouncer and Party Toys

>> Vtc80A High Speed Taiwan Hydraulic Turret CNC Vertical Lathe 800mm

>> Single-Phase Visible 94*94 LED Display Intelligent Digital Voltage Meter

>> 100% Original Videojet 16-8540q 16-845q 16-3601q Ink and Make up Fluids for Cij Printers

>> Silo Cement 1500ton Welded Cement Big Bag Silo Detachable Prices of Cement Silo

>> Wholesale Best Price Bamboo Hotel Tooth Brush Made in China

>> High Quality Anti-Fade 150X22.5mm WPC Decking 3D Woodgrain WPC Flooring Decking Embossed Flooring

>> China Wholesale Mermer Lavabo Ceramic Square Marble Vessel Sink Bathroom Vanity Basin

>> China Famous Brand 4-18m Movable Hydraulic Electric Scissor Lift

>> Hot Sale Kitchen Cooktop China Wholesale 2 Burner Tempered Glass Top Gas Stove

>> China Supplier Fancy Exterior Pivot Solid Cherry Panel Wooden Door Design