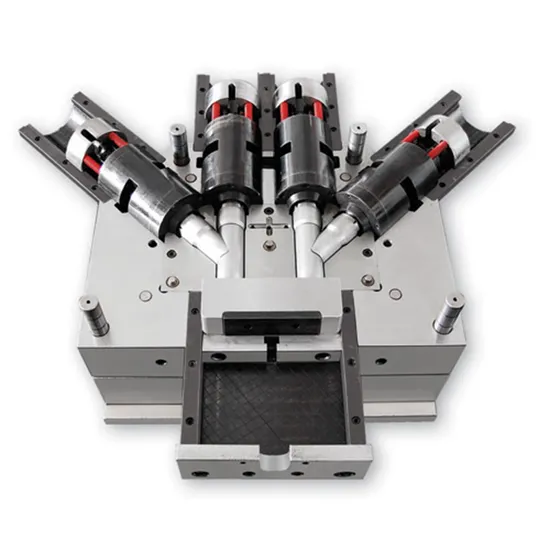

Ware Sanitary PVC Y-Tee Shape Joint 1′′ Plastic Pipe Fittings Injection Mould

| US$1,000.00-3,500.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

Plastic moulds

Surface Finish Process

Polishing

Mould Cavity

Multi Cavity

Plastic Material

PVC

Process Combination Type

Single-Process Mode

Application

Bulidng

Runner

Hot Runner

Design Software

UG

Installation

Fixed

Certification

ISO

Standard

HASCO

Customized

Customized

After-sales Service

Prepare Spare Part

Mould Base

50c&P20

Core&Cavity

1.2344

Cavity

Customized

Color

Customized

OEM

Customized

Platsic Material

PVC&PE&PPR&PP

Surface Treatment

Polish. Etched. Texture

Surface Finishing

Texture Stamp Mat Skin

Transport Package

Wooden Box

Specification

32-350MM

Trademark

Hongchang

Origin

China

HS Code

8480719090

Production Capacity

600

Product Description

Product Description| Place of Origin | Zhejiang, China |

| Model Number | 20-350mm |

| Plastic material | Plastic material |

| Runner | Hot Runner\ Cold Runner |

| Mould life | 1000000 shots at least |

| Cavity | Single Cavity\ Multiple Cavity |

| Certification | ISO9001:2000 |

| Design software | UG PROE CATIA SOLIDWORK CAD |

Detailed Photos

Company Profile

Taizhou Hongchang Molding Technology Co.,Ltd

Zhengjiang Taizhou Hongchang Techonology Mould , located in Zhejiang Huangyan which enjoys the name of "the mould's hometown",we are specialized in designing and making Plastic injection Moulds. After years of hard work in R&D,creation and refining ,HC mould has gathered a team of experienced R&D ,and adopted international advanced CAD/CAM/CAE system, have advanced workshop management system and modern production equipment.

Mould has grown into a superior mold manufacturer with a strong engineering team ,more than 70% of the moulds are exported to Europe, America, theMiddle East,Southeast Asia, Africa and more than 30 countries.

Welcome all customers and potential customers to visit our factory anytime,and establish long-term business relationship with us.

The Company Flow Chart

| 1.Inquiry |

| |

| 2. Quote |

| |

| 3. Negotiation | The material,delivery time,payment ,price and ect. | |

| 4.Place an order | Contract Examing&Commenting. | |

| 5.Mold Design | Mold Structure Drawing and Auditing. | |

| 6.Mold Make | Before making,we send design to customer to approve. | |

| 7.Test Sample | We send the test sample to customer until meet customers'requests. | |

| 8.Delivery | Delivery by sea or according to customers'. |

All native files and IGES,DXF,STEPof the autoparts,ect.Files can be received.

Our Advantages

Core&Cavity material:DIN 1.2316 HRC 50

Cooling systerm:Separate Loop with copper insert

Surface treatment:Best Mirror polishing

Certification:ISO9001:2000

Mold Life:At least 1000000shots

Spare parts:Spring,guid bush,ejctor pins,lifter ring,water nipple,guid pins etc

Hot runner brand:Yudo,Hasky,Incoe

Core Pulling systerm: Motor,oil cylinder,strippling plate,ejector pins etc

Delivery Time:35-60days

Packing box:Wooden Case

Mould standard:DME,HASCO,MISUMI

Mould base: S50C,P20,LKM etc

After Sales Service

| Lifting Ring | Spring | Ejector pin |

Packaging & Shipping

FAQ

1.Good experiences in mould making.All technicians have more than 10 years of work experience.2.Patent in collapsible fitting moulds.3.Machinery core pulling system save cost and increase production efficiency.4.Perfect core pulling distance within 180mm.5.Excellent R&D team.(We can offer you 3D mould design with all details within one day.)6.Efficiency production department.(We can finish Push-Fit fitting mould of size 110mm in stwo cavity with in 45days.)7.Competitive price in save level of mould manufactuers.

>> Healthy Natural Dry Food Vegetables Dried Carrot Minced Carrot

>> Wheat Starch Milk Dehydrator Machinery Wheat Flour Processing Production Line Wheat Starch Making Machine

>> 50 Wholesale Large Mirror Ball Glass Mirror Disco Ball Mirror Ball Disco

>> Woman Seamless Fitness Yoga Wear Legging Black Casual Green Pants Quantity Mesh Customized Maxi Spandex Logo Gray Style Pcs

>> Taijia Heavy Duty Hanging Scale crane load cell Tension Link Load Cell

>> Customized Oil Dewaxing Deoiling Production Line Separation Equipment

>> Shineray Swm G01 G05 Automotive Engine Cylinder Head Cover Plastic Factory Original Genuine Manufacturer Direct Sales

>> Customized Hanging Magnetic Whiteboard Writing Board for Office Supply

>> High Precision Fiber Laser Cutting and Engraving Machine for Steel Sheet Equipment Cutter

>> Quality Ce Manual Hand Chain Hoist 20 Ton

>> Tecture Luminous Laminated LED Glass 40.7mm LED frosted Light Glass

>> Hot Sale Corn Stalk Silage Packing Machine Clover Hay Round Baler Straw Ryegrass Alfalfa Wrapper for Farm Storage Material Conveying and Packaging Machine

>> Durable Bamboo Countertop Basket Bowl Holder Wooden Cabinet Corner Rack for Plate 2-Tier Kitchen Shelf Storage

>> Famou Pig Poultry Equipment 380V Flex Auger Feed Transport System for Livestock Feeding System

>> OEM Mini Tripod Screen 60" 4K OEM Aluminum Case

>> Hr3000 Polyester Pet Bottle Plastic Recycling Machine Washing Line

>> for food soybean green bean sprout making machine

>> Children Small Furniture Set PVC Cartoon Sofa Suit

>> S11 2804533 Automobile rear bumper bucket type bracket for s11chery qq Car parts rear bumper bracket

>> High Quality Free Sample Leather Blazer and Skirt Set PU Leather

>> Cultured Hand Carved Marble Luxury Stone Fireplace Mantel Indoor Decorative Fireplace

>> Heavy Duty Gantry Double Columns Milling Machine

>> Manufacture Wholesale Cheap Mini Pole National Country Polyester Waving Hand Flag

>> Ductile Iron Knife Sluice Gate Valve

>> Speedclean Semi-Sphere Design Mixing Tank for Fast Heat Transfer

>> Gxp Series Hammer Mill Grain Rice Maize Wheat Corn Hammer Mill for Using Animal Feeds

>> Adjustable Wall Light 80W 5 Years Warranty LED Wallpacks

>> Motorcycle Rear Shock Absorber for Cg125

>> Commercial soya milk machine bean curd making machine tofu

>> Quality Priority 50 Gallon Mixing Tank