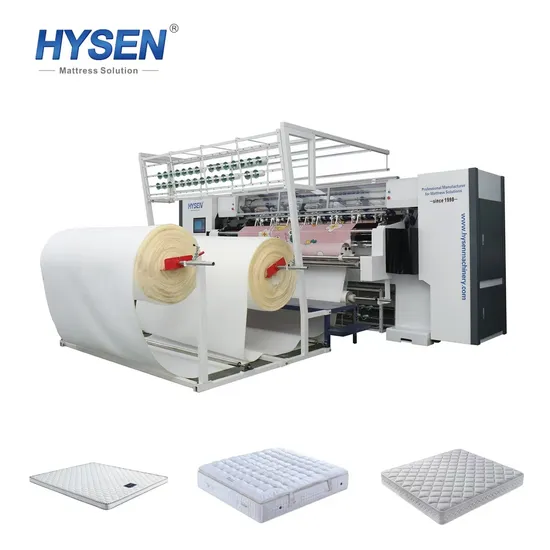

High Speed Shuttleless Quilting Machine Textile Machine Mattress Production Machinery

| US$20,000.00-35,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

HSW3600

Certification

ISO, CE

Condition

New

Number of Head

2

Voltage

380V

Type

Computerized Quilting Machine

Quilting Width

2450

Production Speed

60-230m/H

Main Shaft Speed

1200rpm

Power

6kw

Gross Weight

4100kg

Quilting Thickness

60mm

Transport Package

Wooden Case/Plywood Case

Specification

6000x1200x1700mm

Trademark

OEM ODM own brand

Origin

Dongguan, Guangdong

HS Code

8452219000

Production Capacity

350sets/Year

Product Description

Product DescriptionHSW3600(Add Protective Device) Computerized Shuttleless Multi-Needle Quilting Machine,The needle row adopts a needle bar frame structure, which eliminates the need for oil and avoids oil stains on the fabric. Moreover, this structure is stronger and not easy to be damaged, and the maintenance cost is low. Advanced surface thread breakage detection technology and automatic shutdown function when thread breakage occurs. The CAD drawing method is accurate in graphics, convenient and fast. High rigidity body, high machine operation, light vibration, low noise and no impact, regular refueling function. A new hooking button is added. Press this button and the machine will automatically stop at the hooking position to facilitate customers to install and debug the hook. A new high-position button is added. Press this button and the needle position will automatically stop at the highest position to facilitate needle threading.Added front and rear protective covers for safer operation.

Product Function

1.The needle row adopts a needle bar frame structure and without refueling to avoid greasy fabric. Moreover, the structure is solid and not easily damaged, low maintenance costs.

2.Advanced and practical up thread-break detection technology,auto-stop when thread-breaking.

3.Easy preparation of CAD drawings extremely precise.

4.Outs tanding featllres such as high vigidity high running speed low vibration and noise.

5.New hook line button, press this button the machine automatically stops at the hook line position to facilitate customers to install and debug the hooker.

6.New high position button, press this button the needle position automatically stops at the highest position for easy loading and threading.

7.Added front and rear protective covers for safer operation.

Product Parameters

| Model | HSW3600 |

| Dimension(l*w*h) | 6000x1200x1700mm |

| Quilting Width | 2450 |

| Space Between Needle Rows | 76.2 |

| Space Between Needles | 25.4 |

| X-axis Movement Displacement | 305 |

| Quilting Thickness | ≤30mm |

| Stitch Length | 2‐8 |

| Production Speed | 60-230m/h |

| Model of Needle | 24/180 23/160 22/140 |

| Main Shaft Speed | 1200RPM |

| Power | 6KW |

| Volatge | 380V/50H 220V/60H |

| Gross Weight | 4100Kg |

Product Details

If you want to know more details, please click

| Products Catalogue | Main Products |

| About Hysen Machinery | Mattress Cutting Machine |

| The needle row adopts a needle bar frame structure and without refueling to avoid greasy fabric. Moreover, the structure is solid and not easily damaged, low maintenance costs. | Advanced and practical up thread-break detection technology,auto-stop when thread-breaking. |

| Easy preparation of CAD drawings extremely precise. | Outs tanding featllres such as high vigidity high running speed low vibration and noise. |

Application Range:Mattress,Textiles,Clothing,Bed spreads,Bedding,Comforters and so on.

Our Advantages

*We are a factory with more than 20 years of manufacturing experience.

*Support for customized machines (appearance,color,size,quilting width,etc.) according to your needs.

*We have a one-year warranty.Warranty period parts damage support free replacement, excluding shipping costs.

*We provide in-home installation service.

Company Profile

| Dongguan Hysen Machinery Co.,Ltd. specializes in manufacturing quilting machines, the company has standardized production plants,advanced production equipment,and a group of senior engineers and professional technical developers,forming a complete scientific research,design,production,sales and service system.We have more than 20+ years of production experience, we supply series of product and professional service to numbers of known companies.At present, the main products are quilting machine,automatic four-side hemming machine ,computerized panel cutting machine and tape edge machine , etc.Various products have passed the National Patent Office and CE certification.The products have been sold abroad to Asia, E-urope, America and Africa , etc.We hope we can build the good relationship with the customers all over the world.With cost-effective products and thoughtful warm service to exchange for trust and support, mutual benefit, create a win-win situation! |

Packaging & Shipping

Certifications

FAQ

1.Q:Why Choose Our Company?

A:We have more than 20+ years of production experience, we supply series of product and professional service to numbers of known companies.

2.Q:How's the after-sale service?

A:We have a one-year warranty.Warranty period parts damage support free replacement, excluding shipping costs.

3.Q:ls the price offered changeable?

A. We offer reasonable price for every client, and the price is changeable according to purchasing amount.

4.Q: How about the quality?

A: The main subassembly and raw matetials are all supplied by large companies. Key parts are research and developed by our own staff. profesional assembly line work and strict quality test system can ensure your high quality reguirement.

5.Q:Availability of spare parts.

A:Spare parts we usually stock, but it depends on your needs!

6.Q:Are you a manufacturer or trading company?

A:We are a professional manufacturer holding our own intemational Trade Depalment,for that we can beter understand customers needs and ofer a reasonable price.

>> Servo System Energy Saving Automatic Beverage Drink Plastic Sport Cap Making Gallon Prefrom Bottle Preform Injection Mold Machine

>> Smart Electronic Energy Meter: Single & Three Phase, Lorawan / WiFi / 4G / RS485 with Prepaid Electricity Remote Control and Ami / AMR Solution

>> SFI 16.1 Certified 5 Point Racing Car Shoulder Pad Safety Harness Seat Belt

>> Multi-Functional Sawdust Hammer Mill Made in China with CE Certificate

>> Stationary Concrete Mixing Plant 75m3 Concrete Batching Plant Superior Concrete Batching and Mixing Plant

>> Lifting Magnet for Steel Ball MW5

>> Servo Motor 20L Energy Saving Blow Moulding Machine

>> Factory Wholesale Cheapest Super Bright 200W H4 Car LED Auto Headlight Bulb

>> China Supplier Disposable custom printed food brown kraft paper box packaging

>> Bb Cream Meso White Makeup Liquid Foundation Serum Bb Brighten Glow Whitening Liquid Foundation

>> Grinding Mill for Powder Coating Machine

>> Wholesale Colorful 16.3 Inches Tall Straight Tube Perc Hookah Glass Smoking Water Pipe

>> Automatic Grinder Sharpener Crushing Knife Straight Knife Paper Cutting Knife

>> Wholesale Regular Fit 3XL Pocket Jogger Trousers Mens Cargo Tactical Work Utility Camo Cargo Pants for Men

>> Taijia TEM-H410 Topping Concrete Slab Floor Slab Thickness Gauge Detector

>> Spiral Horizontal Screw Centrifugal Oil Separator, Oil and Grease Centrifugal Separator

>> Hot Sale High Capacity Small Portable Rice Milling Machine

>> Kangqiao Horizontal Pit Plant City Drainage Feed Multistage Single Suction Jet Sewage Clean Water Axial Flow Booster Centrifugal Pump for Chloride Evaporation

>> HOT Kids Toys Shawls Hats Mittens clothes Hanging Mesh Space Saver Bags Organizer hanging baskets

>> Outdoor Sports Toys Cartoon Summer Children Pull out Large Capacity Long Range Water Gun Backpack

>> designs photos models ply teak wood door

>> Fully Automatic Cleaning Strainer with Kinds of Models

>> Sports Windproof Keep Warm Men′s Winter Jackets

>> Sm2-95 16-95 4-35 (50) Sqmm Ipc Insulation Piercing Connector for Lower Voltage Overhead Electrical Distribution

>> Good Quality Chili Mill Wheat Grinder Maize Milling Machine

>> Frt-4032 Double Column Machining Center 3/4/5 Axis CNC Machining Center Heavy Duty Gantry Milling Machine

>> New Design Heavy Duty 20V Cordless Impact Wrench with 2 Batteries

>> Rotary Tablet Press Die Punch Zp9

>> Model S Rear Trunk Opener Electric Tailgate Power Liftgate Door For Tesla Model S Auto Trunk 2012+

>> Widely Use SPHC/SPCC/JIS G3131/1.2mm/10mm/Q345/Q195/Q345b/Painted/Galvanized/Pipe Making/Building/Cold Rolled/Hot Rolled Steel Coil