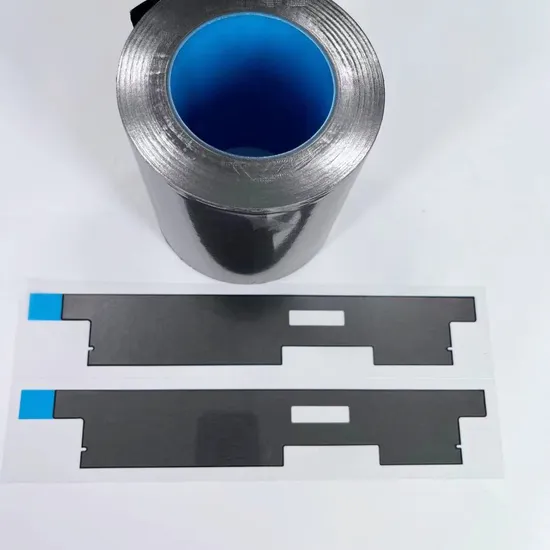

Egraf Hitherm Thermal Interface Materials Ht Series Natural Graphite Sheet Long-Lasting Reusable for Solid-State Lighting Computing Power Electronics

| US$0.50-1.00 | 5,000 Pieces (MOQ) |

Basic Info.

Model NO.

HT series

Product Name

Hitherm™ Ht Series

Thermal Conductivity in-Plane

150/120 W/Mk

Thermal Conductivity Through-Plan

10/16 W/Mk

Thickness

0.127/0.250/0.510mm

Flammability Rating

UL94 V-0

Thermal Impedance @ 200 Kpa

0.59/0.66/0.41/0.58 K-Cm2/W

Thermal Impedance @ 700 Kpa

0.30/0.40/0.24/0.41 K-Cm2/W

Certification

ISO9001/ISO14001/IATF16949/ISO45001

Carbon Content

High-Carbon

Grade

Industrial Grade

Forming Way

Molded Graphite

Crystal Morphology

Flake Graphite

Composition

Carbon

Transport Package

Carton

Specification

customizable

Trademark

Egraf

Origin

Dongguan

HS Code

8473309000

Production Capacity

1000000piece/Year

Product Description

Product Parameters Product Category: HT seriesProduct Overview HT series materials are designed for long-life,mission-critical applications that have extreme heat cycles, require low contact resistance, and high thermal conductivity. When determining which grade and thickness of HiTherm TIM will work for your application, the effective thermal impedance is the critical factor. Thermal impedance combines the thermal resistance at the contact surfaces and the TIM's bulk resistance.

Product Application HT series materials are typically used in the application of IGBTs and power devices,Solid-state lighting modules,UPS and inverters ,Motor drives ,Base stations / telecommunication,Thermoelectric devices ,Power supply modules, rectifiers, and chargers ,High-performance computers and servers,EV / HEV / PHEV power modules.

Technical specification

| Characteristic | Unit | PURE GRAPHITE HT-1200 Series | POLYMER ENHANCED HT-2500 Series |

| Thermal Impedance @ 200 kPa | K-cm2 /W | HT-1205 = 0.59 HT-1210 = 0.66 | HT-2505 = 0.41 HT-2510 = 0.58 |

| Thermal Impedance @ 700 kPa | K-cm2 /W | HT-1205 = 0.30 HT-1210 = 0.40 | HT-2505 = 0.24 HT-2510 = 0.41 |

| Typical Thermal Conductivity @ 700 kPa Through-Plane • In-Plane | W/m-K | 10 • 150 | 16 • 120 |

| Typical Thickness with Tolerance 0.127 mm (0.005") ± 10% 0.250 mm (0.010") ± 5% 0.51 mm (0.020") ± 5% | - | HT-1205 HT-1210 HT-1220 | HT-2505 HT-2510 - |

| Electrical Resistivity In-Plane • Through Thickness | - | 60 • 1230 | 80 • 1550 |

| Hardness (Shore A) | - | 85 | |

| Coefficient of Thermal Expansion In Plane • Through-Plane | ppm/°C | -0.4 • 27.0 | |

| Flammability Rating | UL | 94V-0 | |

| Operating Temperature | °C | -40 to +400 | -25 to +125 |

| Specific Heat @ 25°C | J/g-°C | 0.71 | |

| RoHS Compliant | - | Yes | |

| Lead / Halogen Free | - | Yes | |

Keraf tech is a well-established and professionally managed corporation with nearly 10 years of distinguished record in research and development, production, and marketing of various interface materials and components in China domestic and overseas markets.

After nearly ten years of technology accumulation and intensive development, Keraf group has been transformed from a factory focused on OEM thermal management materials die-cutting production into a comprehensive industrial group with one-stop services such as ODM thermal tech design, hardware and plastic processing, LSR components, industrial coating materials and so on.

Keraf group's core products have covered 3C electronics, semiconductor, equipment, automotive, new energy, photovoltaic power generation, shipping, aviation and other industries to provide a full range of high performance, excellent quality interface material solutions.

Always adhering to the integrity, focus, innovation, win-win business philosophies, Keraf Group have already established and maintained a good cooperative relationship with many global clients. We are also looking forward to becoming one of your reliable and trusted long-term strategic partners.

Certifications

Facilities and Equipment

Our business portfolio

Our Advantages

Packaging & Shipping

>> Automatic Onion Root Cutting and Peeling Machine

>> Professional laser hair removal 3 wave diode laser 755 808 1064 laser hair removal machines price

>> Metal Tube Fiber Laser Cutting Machine Steel High Quality CNC Fiber Laser Equipment

>> Max Fiber Laser Source Single Mode 1500W Cutting for Laser Cutting Machine

>> China Factory Wholesale Hydraulic Bottle Jack Supplier

>> Competitive Full Automatic Log Veneer Rotary Peeling Lathe Exported Europe

>> Industrial flexible control cable

>> Factory Fragrance Oil Perfume for Lady Perfume

>> Good Price Tiller Machine Tiller Machine Agricultural 213cc Power Tiller

>> Automatic Container Mixer for Powder Coating, Masterbatches on Hot Sale

>> Automatic Positive and Negative Pressure Vacuum Forming Machine for Plastic Trays, Food Packaging, Manufacturers Supply Vacuum Forming Machine PP PE PS PC Pet

>> C5225 Manual Double Column Vertical Lathe Gantry Lathe Heavy Turning Cutting

>> Flat Surface Grinder High-Quality Grinding Machine for Various Metal Applications

>> High Quality LNG Micro-Bulk Tank

>> PC Pump Drivehead

>> Two Stage Floor Truck Lifter Jack Pneumatic 100 Ton Air Hydraulic Jack

>> Taijia HT-225 portable concrete test hammer TYPE N SCHMIDT HAMMER

>> Hot Sales Building Material Ceramic Glazed Floor Wall Tile

>> High Speed Facial Tissue Soft Single Bag Wrapping Machine

>> Agricultural Corn Grinder Maize Straw Crushing Machine Feed Hammer Mill

>> Decorative Architecture Staggered Center aluminium perforated sheet metal mesh

>> Foska 12 Digit Solar Power and Battery Office Calculator with Different Colors

>> CAT Grader Cutting Edge

>> 07tj350fdi G. E. T Excavator Parts Bucket Tooth Bolt on Adaptor Tip Casting

>> ABB PM511V16 3BSE011181R1 Module card parts inventory

>> OE 05235377 Crankshaft Position Sensor For JEEP CHRYSLER CIRRUS DODGE AVENGER 37747810 05269703

>> Expanded Metal Expanded Metal Galvanized Stainless Steel Aluminum Steel Expanded Metal Mesh Hot Sale

>> Food with Thermal Noodle Fertilizer Cookies Packing Mango Price Sauce Sachet Packaging Machine

>> Custom Large Outdoor 9X12 Polypropylene RV Mat Carpet Lightweight Recycled Plastic Patio Rug RV Mats for Camping

>> High Speed Laboratory Homogenizer (GJB30-40)