5 Axis Linkage CNC Machine Tools with A axis rotation angle

| US$45,000.00-65,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

UC260

Application

Metal

Process Usage

Five Axis Linkage Milling Machinning Center

Movement Method

Linear Control

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Performance Classification

High-End CNC Machine Tools

Certification

CE, ISO 9001

Condition

New

5 axis

5 axis linkage

machine

turning and milling

Transport Package

Export Packaging

Trademark

JINNFA

Origin

China

Production Capacity

200

Product Description

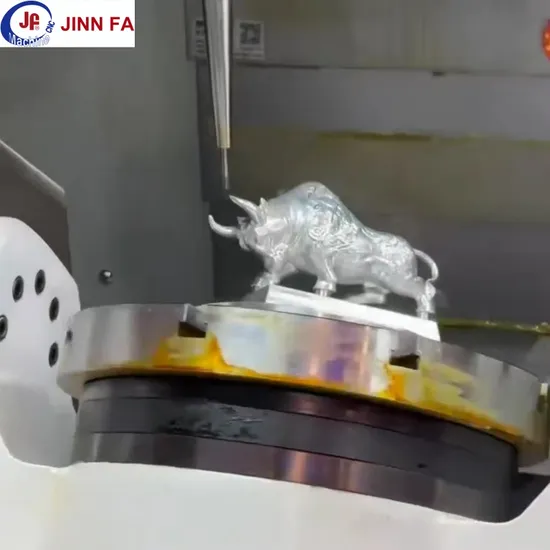

U-C260 FIVE-AXIS FEATURE:The UC series is characterized by a mechanical structure consisting of a spindle and a tilting and rotating worktable, which reserves a large processing area to suppress interference between the workpiece and the tool. The tool can be fed vertically, horizontally, and at any angle enabling a variety of processing with a small number of tools. Moreover, it has a large range of motion to accommodate applications and fixtures with complex shapes.

The UC series can integrate all processes from materials to finished products on a single machine tool. Concentrating the processes into turning and milling processes is expected to achieve the following effects.

+Reduce processing preparation work

+Significantly shorten the production cycle

+Reduce installation fixture costs and equipment costs

+Reduce machine tool footprint

+Minimization of cumulative errors and high-precision machining through intensive processes

Product Parameters

| MODEL | UNIT | UC-260 | UC-320 |

| BASIC SPECIFICATION | |||

| Travel XYZ | mm | 700×550×520 | |

| Spindle nose to work surface (center line) | mm | 100-620(horizontal) | |

| T-slot width | mm | 12H7 | |

| T-slot quantity | degree×unit | 90×4 | |

| A axis rotation angle | mm | -120°~120° | |

| C axis rotation angle | mm | 360° | |

| Spindle | |||

| spindle motor | kw | 11 | |

| spindle speed | rpm | 10-12000 | |

| spindle inner taper hole | BT40 | ||

| Feed axis | |||

| Rapid feed rate(X/Y/Z) | m/min | 36/36/36 | |

| A/C axis maximum speed | rpm | 150(A tilt axis) 300(C Rotary axis) | |

| Fastest cutting feed rate | mm/min | 1-10000 | |

| Positioning accuracy(full travel) | mm | ±0.005 | |

| Repeat positioning accuracy(full travel) | mm | ±0.003 | |

| Tool magazine | |||

| Tool magazine capacity(standard/optional) | set | 24/30/32 | |

| Tool magazine form | tool arm type | ||

| Pull stud form | degree | 45 | |

| Maximum tool diameter(when there are tools in adjacent tool positions) | mm | 76 | |

| Maximum tool diameter(when there are no tools in adjacent tool positions) | mm | 150 | |

| Maximum tool length | mm | 300 | |

| Maximum tool weight | kg | 8 | |

| OTHERS | |||

| Air pressure requirement | kg/cm2 | 7 | |

| Power specifications | AC380±10%,60Hz/50Hz | ||

| Power demand | KVA | 30 | |

| Total machine weight(approx) | T | 5.2 | |

| Overall size(length×width×height) | mm | 2600×3000×3000 | |

| A/C five-axis parameters | |||

| Five axis type | Dual DD direct drive motors | ||

| Disk diameter | mm | Φ260 | Φ320 |

| Maximum processing diameter | mm | Φ380 | Φ480 |

| A Rotary axis motor | nm | 260(Max:460) | |

| C Rotary axis motor | nm | 130(Max:230) | |

| Minimum division value | degree | 0.001 | |

| Indexing accuracy | sec | ±5"(tilt ) ±5"((rotary) | |

| Repeatability | sec | ±3(tilt) ±3"(rotary) | |

| A axis tilt angle | degree | -120°~120° | |

| Load | kg | 60(Vertical) 60(Horizontal) | |

| Note: Our company reserves the right to change the specification without advance notice. | |||

JINN FA Gang Tool CNC Lathe's Advantage:

1: Simplicity and Affordability

Gang tool lathes are often more cost-effective than turret lathes due to the simplicity of their tool change process. The lathe's standard axis servos and leadscrews handle all the work, whereas motorizing a turret can increase costs significantly.

2: Precision

Gang tool CNC lathes have an accuracy advantage over turret lathes due to their simpler moving parts, which reduces tolerance stack up and other types of slop. Additionally, the gang lathe is better suited for moving parts across shorter distances.

3: Rapidity

The tool change process in gang lathes is incredibly speedy as it utilizes slide motion for tool changes, eliminating the need for turret indexing.

4: Quick Installation

Gang tooling lathes offer fast setup times, with a simple set of tools and the ability to switch out a single block for a specific size twist drill allowing for a wide range of gang work to be accomplished.

5: Durability

Gang Tool lathes are known for their robustness, which is directly linked to their simplicity. With fewer moving parts, gang lathes are less prone to errors and malfunctions.

Company Profile

POLOMAC TECHNOLOGY(QING DAO)L.L.C

PROFESSIONAL CNC MACHINING MANUFACTURER & SUPPLIER

We have done a great deal to ensure the quality of our machines meets international standards. To this end, we have rigorous inspection procedures, which are conducted throughout all phases of the manufacturing process. This allows us to ensure the ultimate in quality. This commitment to quality and expert workmanship enables JINN FA to offer machines that fully meet customers' strict requirements of machine performance.

High Accuracy High Quality High Efficiency

JINN FA Machine industrial Co., Ltd. was established in 1976 as a Precision Metal Lathes Machine Tool Manufacturer. JINN FA designs and manufactures a wide range of auto lathes, cnn lathe machines, CNC machining centers and special purpose machines. Based on the company philosophy of technological innovation and leadership, JINN FA has spent great efforts in the research and development of advanced machine tools. Our precision cnc metal lathe machines have been widely sold to many countries in the world. Each metalworking lathe and machine is manufactured to the highest quality standards, with the highest versatility, providing the most competitive edge for parts machining. JINN FA machines are further enhanced by fine craftsmanship, which guarantees the user outstanding precision performance. Today JINNFA continues to labor at the technological forefront of the machine tool industry, maintaining a reputation for innovation design, state-of-the-art manufacturing techniques and rigorous quality control.

JINNFA continues to expand its service market, adhering to the company's belief of continuous technological innovation and technological leadership. In 2001, China POLOMAC TECHNOLOGY Co., Ltd. was established to enable every Jinnfa machine to serve the world.

A highly reputed manufacturer of CNC precision metal lathes, CNC machining centers and special purpose machines.

Certifications

Packaging & Shipping

FAQ

1.What is your minimum order quantity and warranty?

A:MOQ is one set, and warranty is one year.

2.What CNC system do you use?

A:FANUC, SIEMENS, MISTSUBISHI, GSK, SYNTEC. lt depends on your choice.

3:How can l choose the most suitable machines?

A: Please tell me your specifications, we can choose the best model for you, or you can choose the exact model. You can also send us the products drawing, we will choose the most suitable machines for you.

4: What's your main products of your company?

A: We are a machine tool manufacturer that produces CNC lathes, CNC milling machines, vertical machining centers, Swiss style automatic lathes, grinders, and machine tool specific tools and precision parts OEM.

5: Can you come to our company for technical support?

A : Yes, we can provide on-site technical support, but travel and service fees will need to be paid.

6. What is your trade terms?

A:FOB, CFR and CIF all acceptable.

7: What's the Payment Terms?

A:T/T, 30% initial payment when order, 70% balance payment before shipment; lrrevocable LC at sight.

>> Eco-Friendly multi function Metal Iron Wire Laundry Fruit Vegetable Storage Stackable Basket

>> 12m Wheeled Hydraulic Drive Scissor Lift Platform Aerial Work Vehicle High-Rise Buildings for Indoor/Outdoor Use

>> Factory Outlet Automatic High-Speed Honeycomb Cardboard Machine

>> CE Proved 15L 20L Jerry Can Square Bottle Making Blowing Machine

>> High-Quality Car Accessories 5wk96750c 4326864 1710806 Spare Parts Nox Sensor for Auto Use

>> Simple Configuration Vacuum Emulsifier Emulsifying Mixing Machine

>> Organic Bamboo Cutting Board with Juice Groove (3-Piece Set) - Best Kitchen Chopping Board for Meat (Butcher Block) Cheese Green

>> Thermal Break Aluminum Folding Door Aluminium Shop Front Glass Doors

>> China High Quality Precision CNC Aluminum Milling Machining Components Custom OEM CNC Machining Electrical Machined Parts

>> Cimc 3 Axle 45000 Liters Stainless Steel Sulfuric Acid Tanker Truck Trailer

>> Forage Corn Stalk Silage Cutter Adjustable Size Animal Feed Chaff Cutter

>> 8mm Copper Rod Continuous Casting and Rolling Machine for Cable Industry

>> New Quality Agriculture Machinery Combine Harvester for Rice and Wheat Cheap Combine Harvester Available

>> 550 500 mm Window Making Machine CNC Machine Cutting Machine Aluminum Double Head Cutting Machine

>> Automatic good price carbonated sparkling water bottling filling machine for plastic bottle

>> Ceiling Type Single Arm Surgical Lights

>> Versatile Corn Harvester Header Compatible with Various Harvester Brands

>> Taijia TUF-2000SW ultrasonic clamp on flow meter types Fixed ultrasonic flowmeters

>> Electric Golf Cart Truck Style Factory Modified

>> for Mercedes Benz 164 Front Air Suspension Shock Absorber Repair Kit 1643206113

>> Motorcycle Accessories Motorcycle safety Reflective Vest Yog

>> China Factory 304/304L 316/316L GB En JIS Standard Thin Wall Welded Stainless Steel Water Pipe Tube

>> Bell Three Wheels Grab Loader Sugarcane Loader with 1000kg Lifting Capacity

>> Manufacturer′s Direct Sales and Customized Production of Conical Mixer for Feed

>> High Temperature Application Phenolic board and Bakelite Insulation Parts

>> 280GSM Cotton Blank Oil Acrylic Watercolor Painting Stretched Canvas Panels

>> 4 side seal packing machine four sides sealed mask packing machine mask packing machine

>> Centrifugal oil filter machine olive oil filter machine

>> Sole Shredder/Rubber Shredder/Shoes Shredder/Single Shaft Shredder

>> PVC Fashion Slipper for Women Lady Shoes