CNC Hot Punch and Forging Lathe

| US$8,000.00-12,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

WG2-160

Type

Horizontal Lathe

Processing Accessory

Centre CNC Lathe

Guide Rail

Horizontal Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Power Source

Electric

Controlling Mode

CNC

Automatic Grade

Semiautomatic

Setting Mode

Floor-type

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

CIP

160ton

AA

2000

Ab

2080

Transport Package

Pallet

Origin

China

HS Code

8458110090

Production Capacity

10 Units Per Month

Product Description

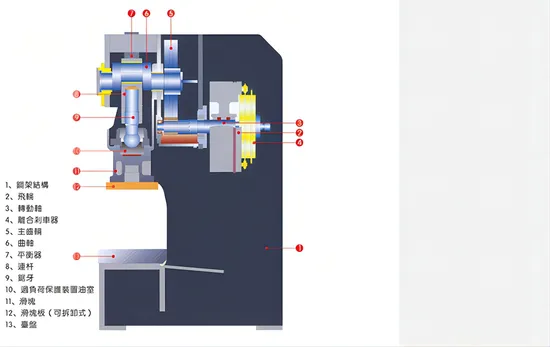

CNC hot forging machine| Technical Parameter | |||||

| Machine type | WG2-110 | WG2-160 | |||

| Model | V | H | V | H | |

| Capacity in punching | Tons | 110 | 160 | ||

| Power produced point | mm | 5 | 3 | 6 | 3 |

| Stroke length | mm | 180 | 110 | 200 | 130 |

| Stroke per minute | S.P.M. | 35-65 | 50-100 | 30-55 | 40-85 |

| Die height[S.D.A.U.] | mm | 400 | 435 | 450 | 485 |

| Maximum counter balance capacity | 5kg/scm | 800 | 1270 | ||

| Slide adjustment | mm | 100 | 100 | ||

| Bolster area | mm | 1800x650 | 2000x760 | ||

| Bolster thickness | mm | 130 | 150 | ||

| Slider area | mm | 1400x500 | 1600x650 | ||

| Slide area | mm | 70 | 70 | ||

| Slider plate operture | mm | 50x3 | 50x3 | ||

| Main motor | Kw x p | 11x4 | 15x4 | ||

| Slide adjusting motor | Kw x p | 1.1x4 | 1.1x4 | ||

| Air pressure | kg/scm | 5 | 5 | ||

| Precision | / | JIS(CNS)class I | |||

| Die cushion capacity | / | 2-Pad-2-Cylinder | |||

| Model | / | D2-240-70 | D3-300-70 | ||

| Capacity in punching | Tons | 3.6x2 | 6.3x2 | ||

| Air pressure | kg/scm | 6.5 | 7.2 | ||

| Trip | mm | 70 | 70 | ||

| Die cushion effective area | smm | 350x235x2 | 410x260x2 | ||

>> Auto Feeding Wc-8h Pto Chipper Shredder, 8 Inches Wood Chipper Mulcher

>> Era PVC Pipe Dwv Fitting Male Adaptor, ASTM D2665 for Drainage, NSF & Upc

>> Commercial Arabic Bread/Naan/ Kulcha/ Chapathi/Roti/Shawarma Lavash/Chapati/Lebanese Pita Bread Machine for Sale

>> Konecranes 2000kg Fixed Type Electric Chain Hoist for Workshop or Warehouse Crane

>> CNC Aluminum Alloy Go Kart 219 Sprocket

>> DDP Shipping Forwarder Logistics From China to Lagos, Harcourt, Apapa, Nigeria

>> Lower Price M5 Electronic Jacquard Module Textile Machinery Parts

>> high strength yellow plastic grating 38*38*38mm FRP floor for car wash

>> 99% Chemical Product Sodium Hypophosphite CAS: 7681-53-0

>> China New 20HP Power Tiller Walking Tractor Cultivators 2 Wheel Walking Tractor South Africa Paddy and Dry Field Plow Machine

>> Mkl229d Wood Pellet Machine Diesel Engine Driven R Type

>> energy saving ball mill grinding machine for gold ore copper ore processing plant cement ball mill

>> TPU PVC NBR Jacket Fabric Layflat Fire Hose Making Machine PVC Lining Canvas Pipe Line

>> Tube Shoulder Injection Molding Machinery Soft Tube Making Machine Tube Shoulder Injection Moulding Machine Prices

>> LWGY Air Turbine Flow Sensor For Liquid Measurement ,Sanitary Turbine Flow Meter

>> Tohan Atc 3D MDF Cutting Working 1325 Caving Drilling Woodworking Milling Wood Engraving Machine Affordable Factory Price for PVC Hardwood Engrave CNC Router

>> Customisable 485c Mini Portable Air Suspension Compressor

>> Multi-purpose fishing Knife Outdoor Fishing Gear Camping Stainless Steel Fish Fillet knife Like Plastic Non-slip Handle

>> Plastic Injection Baby Walker Mould

>> Stainless Steel Seal Nut Expansion Making Machine Stud Hex Anchor Bolts

>> Hone Detergent Mixer Shampoo Making Machine Liquid Soap Homogenizing Body Lotions Blending Machine

>> Floating Glass Staircase With Wooden Treads

>> Swimming Pool Construction Wet Mix Concrete Spraying Machine for Converter

>> Automatic Cosmetic Non Woven Disposable Compressed Towel Making Machine

>> Kingfo Three Four Five Beam Spunmelt Non-Woven Production Line 8 GSM

>> 2024 Large Capacity Brand Women′s Handbag Luxury Handbags Bag Fashion Luxury Mk Hand Bags for Women

>> Sg 450 Circular Saw Blade Sharpening Machine Band Saw Blade Sharpening Machine

>> 150 Tons Shackle Type Wireless Load Cell, Load Shackle, Load Monitoring

>> Industrial ASME Certificated Wood Carbonzation Autoclave with Excellent Performance

>> 14" -42" Adjustable TV Bracket