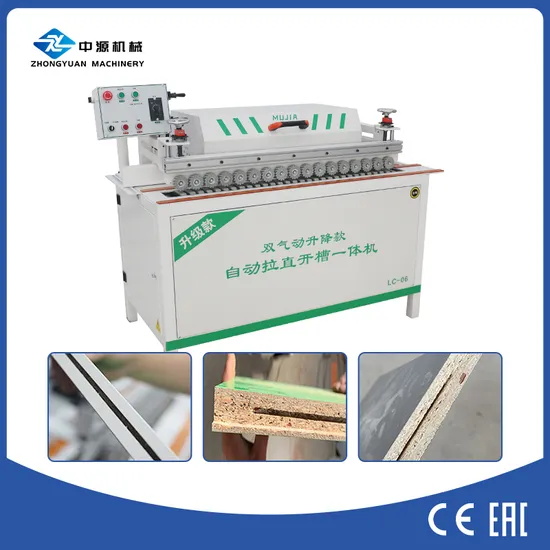

Woodworking Machinery Wood Pallet Grooving Machine Slotting Equipment

| US$2,650.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

LC-06

Spindle Layout

Vertical

Spindle Number

Single-Spindle

Feed Mode

Mechanical

Controlling Mode

CNC

Certification

CE, ISO

Customized

Customized

Condition

New

Color

Customized

After-sales Service

One Year

Voltage

380V Three Fires and One Zero

Frequency

300-400Hz

Total Power

7.8kw

Plate Thickness

1.8-5cm

High-Speed Spindle Motor Power

3.5kw

Spindle Motor Speed

18000r/Min

Slotting Motor Power

4kw

Slotting Motor Speed

2800r/Min

Drilling Diameter

1.27cm

Slotting Depth

0-2cm

Machine Size

1500 *720 *1260 mm

Machine Weight

230kg

Transport Package

Wooden Box

Specification

1500 *720 *1260 mm

Origin

China

Production Capacity

100sets/Month

Product Description

Product ParametersLC-06 automatic straightening and slotting machine

Dual pneumatic lifting model.Quick knife adjustment, safety protection, efficient dust collection.

Function: The door panel can choose the milling slot/milling position (middle, top, bottom) at will, and can also choose full opening or half opening, with a reserved size of 100CM on both sides-full slot.Milling and slotting of the mother-and-child handle, slotting of the straightener, side slots (opening slots, not opening slots).

Features: dual pneumatic adjustment, inverter control, the straightener spindle uses Wang Jiannan's 18,000-rpm high-speed spindle, with stable performance.

5 slotting methods: Side slot opening: slotting depth 0-2cm. Straightener slot: drilling diameter: .27cm. Handle opening: milling edge slotting is completed in one go. Side slotting without opening a slot. Handle opening without opening a slot.

Details:

1.Variable frequency speed regulation for smooth feeding without shaking.

2.Optional pre-cutting function:Prevents edge collapse and extends the service life of the straightening knife.

3.Control panel:Independent control buttons, clear display, intuitive and convenient, strong overall control.

4.Digital display adjustment handwheel:The handwheel can be adjusted according to the thickness of the plate, suitable for a variety of plate specifications and materials.

5.Side slotting motor:The use of high-power motor can realize the opening and closing of the side slot.

6.Pressure beam device:There is an all-aluminum pressure beam device and CNC adjustment function in front of the machine.

7.The double-row silicone pressure wheel automatically feeds the plate and firmly presses the plate to prevent the plate from shifting during slotting, causing erroneous operation, No imitation board, no deviation.

8.Extended ruler:adjustment handle reference ruler, precise scale, one-time molding.

9.Upgraded milling cutter, clamp the milling cutter with the slotting machine, and slot it in a straight line.Spindle motor Special cutter head, milling without edge collapse, no burrs.

10.Dual pneumatic adjustment, flexible tool change, switch to different working modes, convenient and flexible.

| Voltage | 380V three fires and one zero | Spindle motor speed | 18000r/min |

| Frequency | 300-400HZ | Slotting motor power | 4KW |

| Total power | 7.8KW | Slotting motor speed | 2800r/min |

| Plate thickness | 1.8-5cm | Drilling diameter | φ1.27CM |

| High-speed spindle motor power | 3.5KW | Slotting depth | 0-2cm |

Detailed Photos

Product Application

Company Profile

Certifications

FAQ

Q1: I already have an edge banding machine and I would like a trimming machine. Do you have any recommendations?

A: Yes, we have a matching trimming machine. You can choose the product that suits you according to your actual production needs. Of course, we will also ask you some questions, such as plate size, plate thickness, equipment voltage, number of workers, and so on. With so many types of products, there is always one that is suitable for you.

Q2: Can your edge banding machine use PUR adhesive?

A: PUR glue has high requirements for glue pots. We recommend using models such as F14620-3700-3350 for up glue pots, depending on your specific needs.

Q3: Are you a factory or a trader?

A: We are a 20 year source production factory with rich production experience and a total of 8000+customers. We can provide you with thoughtful and accurate after-sales service.

Q4: How should I make the payment?

A: Firstly, you will pay a 50% deposit as a prepayment, and then we will start producing the equipment. After the equipment is completed, I will send you photos and videos, and you can make the remaining payment. After receiving all the payment, we will arrange for the fastest container to ship to you. You will receive the equipment soon, and I will arrange professional technicians to coordinate with you regarding installation issues.

Q5: How long is the delivery time?

A: Conventional equipment takes 10-12 days, customized voltage or other parameters take around 30-45 days.

>> 520mm A2 A3 Full Automatic Paper Roll Laminating Machine with Auto Air Feeding and Auto Cutting

>> Complete 5 liters mineral water bottling plant / filling machine sale cost

>> Hot sale manual candle making machine price wax candle making machine

>> 2019 Machine to Make Disposable Paper Cup Manufacturing Machine

>> Factory Supply Super 6000-10000 Mesh White Calcined Kaolin

>> Fcb-EV9520L Sony Full HD Lvds 30X Zoom Block Camera

>> Spacious Family Camping Tent with Quick Setup and Stability Party Tent

>> Multifunction Woven Label Cutting Machine/ Hot and Cold Printed Garment Fabric Label Cut and Fold Machine for Satin Ribbon, Cotton Tape, Care Label Jz-2817

>> New Style Custom Pattern Fashion Polyester Bow Tie

>> Goji Berries From Ningxia, China

>> Multi-Leg Polyester Webbing Round Sling Rigging Assembly

>> 10 Gallon Compact Foldable Decorative Outdoor Theme Park Garbage Can Plastic Injection Molding Machine

>> infusion sets disposable blood infusion set with filter for blood transfusion

>> Modern Round Pink Injection Wall Mirror Decoration Living Room Geometric Glass Decorative Simple Wall Mirrors

>> 4G Dual Lights PT Outdoor Camera Human Detection Solar Battery CCTV Camera Outdoor Home ATM Office WiFi 4G PIR Security Camera

>> Gtop Series Intelligent Illumination Seed Germination Incubator

>> Hot sale and best quality 5L PET stretch blow molding machine machinery

>> Cardboard Recycling Machine/Carton Shredder/Cardboard Shredder

>> Industrial Kitchen Equipment 10lx2 Commercial Freestanding Electric Split Tank Turkey Chips Chicken Deep Fryer, 2 Tank 2 Basket, CE Approved (DF-10L-2)

>> Hepatic disease and colon disease detection Non-invasive and radiationless medical examination

>> High Quality 20W 30W 50W Fiber Laser Marking Machine for Jewellery Metal and Nonmetal

>> 15mm Home Improvement Environmentally Friendly Indoor Composite Flooring 0771

>> 10HP Mini Rotary Tiller/Power Tiller/Small Agricultural Land Machine/9 HP Cultivator

>> IEC C14 with Double Fuseholder Power Entry Module Medical AC Power Socket

>> Sixth-Floor 35MPa Wire Multi-Spiral Hydraulic Rubber Hose

>> DHL Freight Forwarder Courier Air Express Shipping Dropshopping Delivery Door to Door Service to Poland

>> X1LG Self-Generator LED Mini Head High Speed Handpiece Turbine CE

>> Hollow Block Making Machine Qt4-40 Manual Interlocking Brick Making Machine

>> 500 Yards Curling Ribbon-Balloon String for Art&Craft Decoration

>> Vacuum Diamond Hole Saw