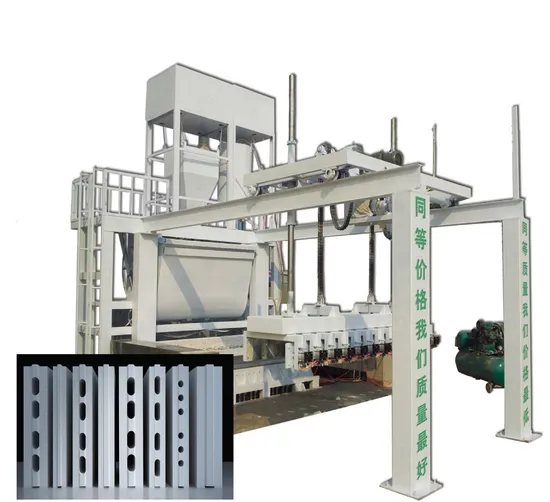

Gypsum Block Making Machine Automatic and Hydraulic Equipment Hollow Block Machine

| US$85,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

DL-1000

Certification

CE, ISO

Customized

Customized

Automatic Grade

Automatic

Type

Hydroforming

Size

60, 70, 80, 90, 100, 120, 150, 200mm Thickness

Color

Customized

Productioncapacity

5-7times/Hour

Rated Pressure

19MPa

Maximum Pressure

31.5MPa

Rated Voltage

380V

Voltage

220V

Power

40kw

Production Worker

3 People

Area Covered

80m2

Working Life

Over 10 Years

Weight

25 Tons

Block Material

Gypsum Powder, Water

Transport Package

Wood

Specification

7x8x10m

Trademark

DALU

Origin

China

HS Code

8474802000

Production Capacity

70-700PCS Per Hour One Machine

Packaging & Delivery

Package Size

100.00cm * 200.00cm * 300.00cm

Package Gross Weight

1000.000kg

Product Description

Machine DescriptionGypsum block making machine ----------- Free design drawings, technical discussion, select suitable gypsum block equipment.

------------ Since 1999 Experience in gypsum technology research.

------------ Direct factory, company legal person direct negotiations here.

Equipment characteristics:The left and right walk of the block fixture is favorable for convenient transportation, convenient operation of workers and

equipment, and avoids the danger of workers operating equipment under the clamp and improves production capacity.

1. The utility model has the advantages of reasonable structure, low energy consumption, high output, small noise, convenient operation, small occupation area, and accurate product size.

2. The mould is made of hard chromium plating, which is not easy to rust and increase the service life.

3. Automatic telescopic fixture, automatically block blocks, put blocks, save manpower, reduce labor intensity.

4. The control system adopts touch screen and programmable controller PLC, equipped with data input and output device, real-time display system running state, found fault, prompt alarm. The control system has the self-locking function, avoids the misoperation to produce. The remote fault diagnosis can be realized by telephone connection, and the production of the customer can be carried out in real time.

5. The blocks are automatically metered into the mixer using a variety of additives, (equipment upgrades).

Process flow and configuration:

Building gypsum powder as raw materials: natural gypsum powder, desulfurization gypsum powder, phosphogypsum powder, special additive, fiber reinforced material, light agent material perlite, negative material, fly ash, etc..

The raw material is stirred by water and poured into shape. After drying, a new lightweight partition product - high precision gypsum block. The utility model is mainly used for frame structures and other non load bearing walls, and is generally used as an inner partition board.

Technical specification

| Capacity | 6-8times / hour |

| Rated pressure | 19 MPa |

| Maximum pressure | 31.5 MPa |

| Rated voltage | 380 V |

| Power | 30 - 60 KW |

| Workers requirement | 3 - 5 persons / shift |

| Area covered | 80 m2 |

| Workshop height | 6 m |

Model Size Flow Process

Customize the size of the gypsum block:

Process flow and configuration:

Start control cabinet → automatic water mixing machine → automatic raw material to screw conveyor → automatic metering hopper → special additive → pneumatic valve unloading material → mixing machine → start the hydraulic pouring molding box → automatic scraping groove → gypsum block forming ejector → automatic palletizing fixture palletizes into two layers of cubes → forklift lifts gypsum block cubes storage or production.

Construction Situation

Natural drying gypsum blocks. Palletizing gypsum blocks. The way of construction:

We offer technical methods for FREE.

Factory Introduction Advantage

Shandong Dalu New Material Environmental Protection Technology Co., Ltd.

-------- Direct factory, company legal person directly receive negotiations here.

We a national professional manufacturer of energy-saving and environmental protection wall material mechanical equipment in China. Our company was founded by father in 1999 and was originally named LIU'AN DALU Building Materials Machinery Group.

We have fully implemented the ISO9001 quality standard system certification and can customize various specifications of high-precision gypsum block production lines, prefabricated wall panel production lines, and composite insulation block production lines according to customer needs.

We assemble and manufacture over 1000 sets gypsum brick equipment every year and export them to the world. Our company has comprehensive Chinese high-tech enterprises including market research, technology development, equipment manufacturing, sales, after-sales service, free technical consultation, and free visits.

Our factory is located in Changqing District, Jinan City, Shandong Province, with beautiful mountains and waters. The registered assets of our company are 5 million dollars, covering an area of 80 acres and a factory area of 10000 square meters.

Our company has successively passed the quality management system certification, applied for multiple utility models and invention patents, and achieved scientific and technological achievements.We have also organized the preparation of multiple technical specifications and atlases for the application of prefabricated lightweight gypsum composite panels, high-precision prefabricated gypsum blocks, and internal partition walls.

Currently, the monthly shipment volume can reach up to 100 sets. Over the years, we have been investigating the gypsum block customer manufacturers, visiting and learning the production process. Through learning from each other, we have absorbed the essence of the industry, and combined with our leading technology in the gypsum block equipment industry for more than 20 years, we have developed high-precision and high-capacity gypsum block equipment.

Willing to create brilliance with you together.

Factory Advantages:

Professionalism

Research gypsum machinery for 20+ years, professionalization and focus, we do not study other unrelated products

Fast delivery

We currently have two workshop and nearly 100 people manufacturing gypsum block equipment. We can complete a large gypsum block equipment in about 50 days, and we have been Top one in the Chinese market.

24-hour service

We have several professional staff who are responsible for receiving messages from customers 24 hours a day and providing technical support during the machine production process.

Engineers around world

Our factory cooperates with mechanical engineers from many countries. Customers can choose engineers from nearest countries to install equipment.

There are many gifts

At the time of delivery, we give many consumable parts free of charge, such as rubber rings button etc, and customers can replace the wearing parts freely. Next days,if customers also need wearing parts, we still send them free of charge.

Free technical advice drawings before sale

Free contact for the most suitable machine. Free professional design, including plant layout, machinery diagram, equipment list, ect for each customer especially. Exhibition Important Clients

We have cooperate with different clients all over the world,more than 100 countries!

And get excellent feedback!

Factory Certification

Our factory created own brand.

Our factory through the ISO9001 quality testing certification and a series of quality certification patent certificates and we are China's high-tech enterprises.

We accept different countries with different requirements of the certificate declaration, about 7-10 days to get the certificate.

Delivery

After-Sales Service

1. We supply all technical surports for raw material supplier information.

2. Our process/ installation/ electricity engineers will stay at your plant until your workers know how to produce good products.

3. After installation, we will test your production, and sign agreement with your workers after succesfully testing.

4. 24 hours technical support by phone, email or skype (email or skype).

5. One years warranty period.

6. Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

7. By offering this support, we make sure the cutomer start the business smoothly, to realise win-win cooperation.

8. Delivery is not the purpose, our purpose is to improve the customer's construction technology, we provide free technical guidance.

FAQ

1. When can we arrange shippment?

We usually arrange shippment within 20days after getting deopsit,

but customized machines should be more than 30days.

2.What you can do if my machines have problems?

1) We can send you free components to you if your machines are in guarantee time.

2) We can send our engineers to repair your machines

3.Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.

4.What is the gypsum block?

A: Gypsum Block is a kind of light walling material, made by Gypsum Powder and adhesive material, mixing with water and being molded and dried.

5.What is the advantage of Gypsum Block?

A: Environment-protection andEnergy-saving, right now they are the most popular in China now.

6.How many types of Gypsum Block so you have?

A:Hollow Gypsum Block and Solid Gypsum Block. Hollow blocks are more popular.

7.Normally where can I use the gypsum blocks?

A: It is widely used in building as inner partition wall.

8.Why we use them as partition wall?

A: Light weight / Fixed shape dimension / Fire-proof / Shock-proof / Heat insulation

9.What is the regular size of gypsum blocks?

A: The regular size of blocks is 666 (600)*500cm, the thickness will be 80 / 90 /100 /120 / 150 / 200mm, Definitely we can

modify other sizes too

10.What is your Gypsum Block's performance?

A:Air sound insulation: 40.5db;

Fire resistance:186min;

Flatness: ≤1mm/m2;

11.What is the working capacity of your machine?

A: Normally 6-8 molds / hour

12.How does your machine come to me?How many parts do you have?

A:Molding machine / Mixer / Hydraulic station / Control panel / Screw conveyor / Water metering bin / Powder metering bin /Mechanical arm clamp / Ground clamp

13.What is your machine's working voltage and power?

Voltage: 380V(+/-10%~15%), 3 phase

Power: 19KW-25KW

>> Mattress Manufacturer Fireproof Fabric Luxury Mattress Topper Remove by Zipper

>> New Automatic License Plate Barrier Access Control IP Camera Recognition Saudi Arabia Number

>> Roof Roofing Corrugated Gi Galvanized Steel Metal Tile with Hot Dipped Zinc Coated Q195 G350 G550

>> Small Electric Mini Sewing Machine Household Use Automatic Condition for Industrial & Manufacturing Plant for Leather Use

>> Affordable Memo Book with Customized Logo for Everyday Writing

>> Recycled HIPS Additives HIPS Storage Box Anti-Breaking Plastic Impact Modifier

>> PVC HDPE Pond Liner Plastic Seam Welders Geomembrane Polypropylene Hdpe Dam Liner Hot Wedge Welding Machine Maquina de Soldar

>> Fast Speed Electric Winch 10 Ton with Double Drum

>> Anti Dust Disposable Mob Cap For Food Industry

>> Universal Valvetronic Muffler Exhaust Electric Remote Control Valve

>> Body Lotion Paste Cream Making Machine Vacuum Homogenizing Mixer Toothpaste Emulsifying Cosmetic Manufacturing Machinery Equipment

>> Aiko Bifacial Double Glass 625W 595W 600W 605W 610W 615W 620W Max 24% Efficiency Mono Solar Power Panel for Distributor

>> Big Smooth Circle Earrings Basketball Brincos Celebrity Brand Loop Earrings for Women Jewelry

>> OEM Hot Style Ultra-Fine Black Eyeliner Waterproof and Non-Smudge Lyeliner Pen

>> Semi-automatic Ultrasonic Display PSA Trading Sport Card Slab Cases Welding Machine Plastic Welder

>> Factory Directly Insulating Structural 250 MM Diameter Cast MC Nylon Rod Sheet

>> Busbar Processing Machine Punching Shearing and Bending Busbar Processing Machinery Economical Single-Motor CNC Three-in-One

>> HIMA F7126

>> EVA Lady Garden Clog Fashion Sandal

>> Waist Trainer Shapers Belly Trimmer Band Tummy Tuck Wrap

>> Rbt CNC Drilling Tapping Boring Machine for Brass Bathroom Fittings/Hardware Sets/Accessory/Towel Ring/Towel Rack

>> Durable Stainless Steel Cover Custom Stamp Caps Metal Stamping Custom Design OEM

>> PVC Profile Production Machine PVC Profile Extruder

>> Concrete Floor Grinding Machine Polishing Machine Road Construction Machinery

>> Factory Price Fiber Laser Marking Machine 20W 30W 50W Marking on Metal and Non-Metal

>> 48GSM Small Thermal Paper Roll Good Price

>> High Quality Engine Spare Parts Fuel Filter Cartridge 04506917 for Deutz 2012

>> Magnetic Stirrer Magnetic Mixer with Stir Bar 1500 Rpm Max Stirring Capacity 20L

>> Vibrating Disk M9 M10 M11 M12 Hex Weld Nut Thread Hex Cap Nut 19b Nut Threading Machine

>> ASTMD3822 Standard Test Machine For Tensile Properties of Single Textile Fibers