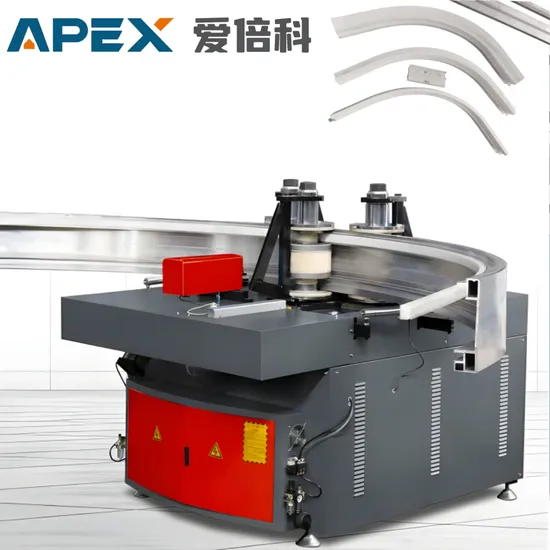

2024 Automatic 3 4 Axis CNC Aluminum Profile Alloy Broken Bridge Aluminum Doors and Windows 40t 30t 25t 20t Roller Rolling Bending Machine

| US$6,900.00-15,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

LWYJ-80-40T

Condition

New

Certification

ISO, CE

Automatic Grade

Automatic

CNC or Not

CNC

Voltage

380V

Power Supply

3phase 380V 50Hz or Customized

Input Power

13 Kw

Working Pressure

0.2MPa

Min Diameter of Bending

200mm

Max Width of Profile

180×320mm

Max Diameter of Rolls

280mm

Lower Shaft Center-Dimensions

500-920mm

Hydraulic Cylinder Pressure

40t

Rolls-Holding Shaft Diameter

80mm

Rotation Speed of Shaft

1-8r/Min

Positioning Precision

±0.01mm

Top Roll Runout

300mm

Torque

4500n.M

Overall Dimension

1840mm*1360mm*1350mm

Machine Weight

2500kg

Transport Package

Wooden Cases

Specification

CNC Aluminum Roll Bending Machine

Trademark

APEX

Origin

China

HS Code

8462911000

Production Capacity

100000 Set/Year

Packaging & Delivery

Package Size

184.00cm * 136.00cm * 135.00cm

Package Gross Weight

2500.000kg

Product Description

Technical Parameters| Model | LWYJ-80-40T | LWYJ-80-30T | LWYJ-60 | LSWYJ-60/65 |

| Power supply | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Input power | 13KW | 12KW | 7.5KW | 10KW |

| Working pressure | 0.2Mpa | 0.2Mpa | 0.2Mpa | 0.2Mpa |

| Min diameter of bending | 200mm | 180mm | 60mm | 60mm |

| Max width of profile | 180×320mm | 150×320mm | 150×180mm | 150×180mm |

| Max diameter of rolls | 280mm | 230mm | 230mm | 200mm |

| Lower shaft center-dimensions | 500-920mm | 485mm | 380mm | 350-750mm |

| Hydraulic cylinder pressure | 40T | 30T | 20T | 20/25T |

| Rolls-holding shaft diameter | 80mm | 80mm | 60mm | 60/65mm |

| Rotation speed of shaft | 1-8r/min | 1-8r/min | 1-8r/min | 1-8r/min |

| Positioning precision | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

| Top roll runout | 300mm | 200mm | 260mm | 200/280mm |

| Torque | 4500N.m | 6000N.m | 3500N.m | 2500N.m |

| Overall dimension | 1840*1360*1350mm | 1950*1380*1620mm | 1570*1000*1275mm | 1300*1100*1500mm |

| Machine weight | 2500kg | 2200kg | 1600kg | 1000kg |

| Model | LWYJ-60/65 | LLWYJ-60/65 | LWYJ-130-65T | LWYJ-30 |

| Power supply | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Input power | 5.2KW | 5.15KW | 22KW | 1.85KW |

| Working pressure | 0.2Mpa | 0.2Mpa | 0.2Mpa | 0.2Mpa |

| Min diameter of bending | 60mm | 60mm | 200mm | 30mm |

| Max width of profile | 150×180mm | 150mm | 200×400mm | 90mm |

| Max diameter of rolls | 200mm | 180mm | 300mm | 90mm |

| Lower shaft center-dimensions | 350-750mm | 350mm | 630-1300mm | 85mm |

| Hydraulic cylinder pressure | 20/25T | 20T | 65T | Mechanical transmission |

| Rolls-holding shaft diameter | 60/65mm | 60/65mm | 130mm | 30mm |

| Rotation speed of shaft | 1-8r/min | 1-8r/min | 1-8r/min | 1-8r/min |

| Positioning precision | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

| Top roll runout | 200/280mm | 150mm | 390mm | 90mm |

| Torque | 2500N.m | 2500N.m | 9000N.m | 1750N.m |

| Overall dimension | 1300*1100*1100mm | 1000*800*1600mm | 1840*1780*1660mm | 1010*560*1035mm |

| Machine weight | 1000kg | 800kg | 3000kg | 400kg |

Our Advantages

Product details and features

Production Process

Packaging & Shipping

Company Profile

After Sales Service

1.One year warranty time, we can repair and replace parts for free in one year.

2.Technical support in 24 hours online, TM, Skype, E-mail, solving the relative questions in time.

3.Life time free maintenance service.

4.Free training course at our factory with professional engineers.

5.We provide the consumable parts at agent price when you need replacement.

FAQ

1. Q: Are you a manufacturer or trading company?

A: Yes, we are a manufacturer.We are focusing on metal pipe/tube processing machines production.

2. Q:Where is the nearest airport to your company?

A: JINAN Airport.

3. Q: How to choose the pipe/tube bending machines?

A: You have to inform us following details:

- Pipe Outdiameter Range

- Wall thickness range

- Bending Radius Value

- The pipe material

- Bends Number on one pipe

- The drawings if possible

4. Q: What certificate do you have?

A: We have both ISO and CE certificate.

5. Q:How about your service?

A: Before Sales Serive:

1. We will help our customer confirm the right model according to the offered pipe inforamtion.

2. Welcome to visit our factory to see our machine and our workshop before you place an order.

>> P10SE-130042 Direct drive flat bed home furnishing and car interior industrial sewing-machine

>> GSK/Fanuc/Siemens Automatic Horizontal CNC Lathe Frame Ck6136 Ck6140 Ck6150 Metal Torno Lathe Price with Electric Hydraulic 6/8 Station Tool Turret Lathe

>> Large factory direct sale automatic weighing french fries packing machine for snack Potato chips

>> Tongjia 7L 15L Double Station Gallon Plastic Bottle Blow Moulding Machine

>> 350-E-P5-G5-H-E-S-N-N-1E-D-N

>> 2024 Factory Direct Trade 33mm Portable Pan Tilt Sewer Camera with Locator

>> Customized Sports Teams / Colleagues / Company Logo Charm Beads Stainless Steel Metal

>> SHENGKE Watch for Women and Men K0120G Unisex Handwatch Night Lught Function Watches Chic Watch Wrist

>> Heart Shape 4.0mm~10.0mm Faceted Semi Precious Gemstone Purple Rhinestone Crystal Stone Price Good Quality Jewelry Making Natural Amethyst Stainless Keyings

>> Quickdry Comfort Baby Pant with Leak Cuff Hydrophilic Nonwoven

>> CAS 7778-77-0 MKP /Monopotassium Phosphate White Powder

>> Wholesale Cheap Disposable Big Diapers for Big Kids/Older Kids OEM&ODM Hot Sale Super Dry Hypoallergenic Baby Diaper Pull up Diaper

>> Pile Integrity Tester (PIT) for Low Strain

>> wood barker tree barker

>> CE Certification, Multi-Function, Three-Point Suspension, Agricultural Tractor, Soil Turning Rotary Tiller

>> High Luminous Efficacy 2700-6000K 2828 40W 60W 50W 80W LED COB Chip for LED Floodlight

>> Factory outlet Multi-function fresh fruit vegetable packing machine

>> Hydraulic Pump Portable Concrete Trailer Pump Cement Beton Pump Small Used Stationary Concrete Pump

>> Security fence expanded metal fencing panel for garden

>> 2020 China factory Portable Wholesale 42.2pint/D Home Electric Dehumidifier 20liter

>> White Appearance 15D X 64mm Hollow Conjugate Siliconized Polyester Fiber

>> Hot Sell Crawler Mini Excavator Construction Machinery Micro Excavator

>> Pio All in One Computer Case, Frame-Less 23.8′′ with FHD LCD Panel

>> 7PCS Screw Driver Bits Set for Electric Screwdriver and Hand Tools

>> HC-R082 Dog use Disposable Artificial Insemination Semen Catheter Uterine AI Catheter Kit

>> for Ricoh 1060 1075 2051 2060 2075 5500 6000 6500 7500 8000 8001 9001 9002 Typ 24 Type Carrier Iron Powder Developer

>> High Speed Automatic Embossing Color-Printing Paper Napkin Making Machine

>> MAICTOP car front spoiler for landcruiser FJ200 2016-2021 limgene pilot kit

>> 200 pa water tightness high performance glass louvre window ventilation for house hinge hardware

>> 2024 New Type Recycle Plastic Film Squeezer Machine for PE LDPE LLDPE Film Bag Plastic Squeezing Washing Line