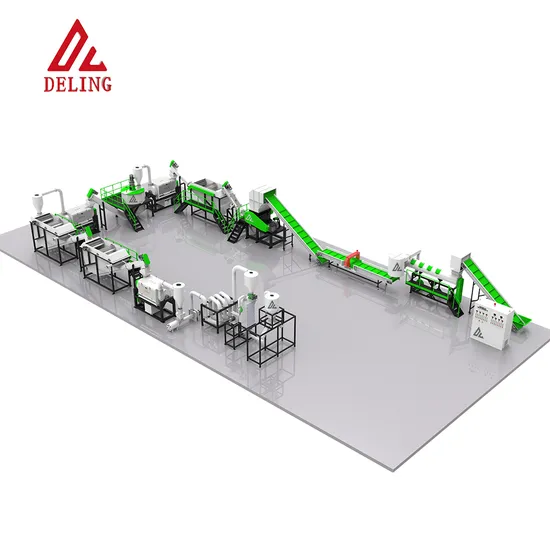

Deling Industrial 300kg/H Pet Bottle Recycling Machine Line with Integrated Washing Crushing Drying and Shredding Functions Equipment Machine

| US$11,140.00-68,580.00 | 1 sets (MOQ) |

Basic Info.

Model NO.

pet recycling line

Material Processed

Plastic Bottle

Plastic Type

PET

Screw

Double-Screw

Automation

Automation

Computerized

Computerized

Condition

New

Machine Type

Pet Bottle Washing Line

Weight (T)

20

Dimension(L*W*H)

25mx5mx7m

Production Capacity (Kg/H)

500 - 3000kg/H

Automatic Grade

Automatic

Warranty of Core Components

1 Year

Power (Kw)

200

Max.Production Capacity (Kg/H)

3000kg/H

Video Outgoing-Inspection

Provided

Key Selling Points

Automatic

Voltage

380V,50Hz,3pH(According to Customer)

Application

Plastic Bottle Recycling Machine

Machinery Test Report

Provided

Transport Package

Land and Sea Transportation

Specification

304 stainless steel

Trademark

DELING

Origin

Jiangsu, China

Production Capacity

40 Sets/Month

Packaging & Delivery

Package Size

500.00cm * 500.00cm * 500.00cm

Package Gross Weight

500.000kg

Product Description

This state-of-the-art PET bottle cleaning line is meticulously designed to start with de-labeling and sorting. Once sorted, the PET bottles are conveyed to the crusher for efficient crushing. The resultant crushed materials are then transported by screw to the rinsing stage, ensuring thorough cleaning. Following this, the materials advance to the friction machine for intense friction cleaning. Post-friction, materials are heated in the steamer and stirred, followed by additional friction cleaning. After this critical phase, the materials undergo two more rinses in the rinsing machine. Subsequently, they are dehydrated in the dewatering machine and proceed to the drying system for optimal drying. Finally, the perfectly processed materials are delivered to the storage bin, completing the comprehensive equipment process seamlessly.

PET Bottle Flakes Recycling Washing Line

Belt conveyer → Rolling separator → Manual pick table → Metal detector → Belt conveyer → Label Separator → Belt conveyer → Crusher → Hot washer → Friction washing → Washing tank → Dewatering machine → Hot air drying system → Label Separator → Pipeline conveyer → Storage hopper → Finished product packing

Components

Product Photograph

Q: Are you a manufacturing factory or a trader? A: We are a professional manufacturer ofcleaning line and granulation equipment, located in Zhangjiagang city, China.

Q: Which type should I use for my recycling plant? A:To recommend the most suitable model for your needs, please provide details of your material's composition, size, handling capacity, and the expected finished product.

Q: Can we visit your factory? A: We warmly welcome your visit! Once we have your schedule, our professional sales team will arrange to follow up on your case and ensure your visit is informative and productive. Q: How to make the payment? A: We accept payments via T/T, Western Union, Cash, or L/C. For T/T payments, customers can either pay 100% in advance or 30% in advance, with the remaining 70% balance paid before shipment.

| Choose our worry free after-sales service | | | | | ||||

| Installation Installation manual and a guide video will be provided. What's more, We can also send engineers to your site for instructing installation, debugging machine and training workers once you required. | | | | | ||||

| Warranty During the one year guarantee period, we change those damaged original components and parts free. | | | | | ||||

| Technical Guidance all life Just call us if any problem you encountered when the whole line in operation, our technician will give you a solution within 24 hours. | | | | | ||||

Please Contact Us

>> macadamia silo miel de shredded coconut macadamia

>> Magic Keyboard Long with Numeric Keypad with Logo British English - Silver

>> Heavy-Duty Twin Shaft Shredder for Efficient Carton Box Disposal

>> Outdoor S M a Aerial WiFi Antenna with Cable Transmitter Long Range Receiver 25dB Amplified HD Digital TV signal Indoor Antenna

>> Agricultural Machinery Parts Under The Rope Tray 000037.3 for Claas Sheaf-Binding Machine

>> High Efficient Pto Driven 4/5/6 Discs Steel Knife Mower Tractor Hay Mower Squeezing Mower for Small Tractor Flail Mower

>> Plastic ABS PP Headboard Side Rail Hospital Board Toy Bed Blow Molding Making Machine

>> Large Capacity Plastic Bottle Water Bottle Bale Breaker

>> Polyester Spandex 4 Way Stretch Fabric for Sportswear Swimwear Yoga Pants

>> Experienced Foundry Manufacturing Auto Aluminum Alloy Die Casting Custom Service

>> Wise Retail Store Widely Used Am/RF Cloth Security Mini Pencil Tag EAS Anti Theft Alarm System Hard Tags

>> High Quality Stainless Steel Dry Powder Mixer Machine Powder Mixing Solutions

>> hemp seeds dehulling machine / hemp peeling machine / decorticator for different kinds hemps

>> Ex1200 1200W Two Speed M14 Electric Mixer Tool Power

>> Solid Pipe Extrusion Line PPR Pipe Extrusion Line

>> Low Power Consumption Heating And Cooling 24000Btu 220V Air Conditioner For Sale

>> China Suppliers Tiffany Style Floral Table Lamp 8 Inches

>> Designer Light Sneakers Jogging Shoes Running Women Men Flats Classic High Quality

>> Laser Protective Glass 21.5*2 mm Laser Cutting Consumables Laser Protective Glass Laser Lens Laser Quartz Lens Laser Nozzle

>> Hight Quality Wholesale Toys Pull Wire Deformation Plane with Lights

>> Large Pressure Electric 12V 24V DC Mini Vacuum Pump

>> Top Quality Single Screw Dry Extruder Machine for Feather Powder Processing

>> Versatile Electric Hybrid Lifting Table for Enhanced Work Efficiency

>> Commercial Incubator Accessories Spare Parts Exhaust Fan for Incubator

>> High Quality and High-Speed Automatic Cardboard Box Printing Slotting Die Cutting Machine with Stacking Machine

>> Foldable Enclosure Tent Camping Wall Fence Partition Privacy Shield Waterproof Windbreak Outdoor Wind Shield Bl21023

>> Seto Phone 180 Degree Straight Coupler Rj11 Cat3 Keystone Jack

>> UK5 semi automatic Hot thermal glue spine book binder, hotmelt eva glue notebook binding machine

>> Reusable Logo Printing PP Bulk Plastic Jumbo Big Ton Bag

>> Wholesale Cosmetics Own Logo Eyebrow Pen with Brush Tube Private Label Eyebrow Pencil Packaging