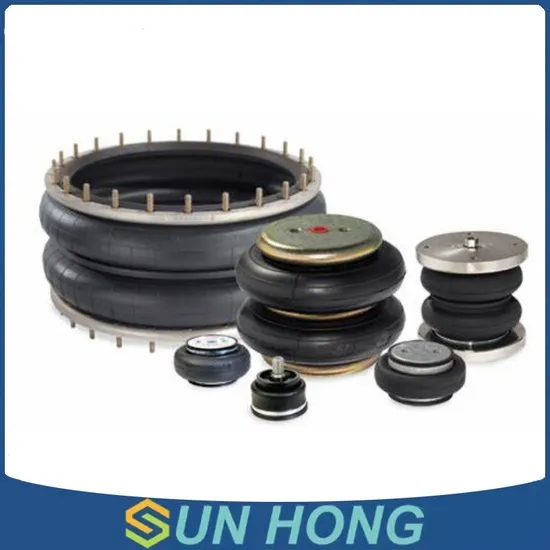

Paper Making Machine Mill Industry Rubber Adjusting Customized Air Spring Bellow

| US$10.00-20.00 | 1 Piece (MOQ) |

Basic Info.

Certification

CE, ISO

Surface Treatment

Without Processing

Material

Rubber

Condition

New

Customized

Customized

Pressure Ability

2-8 MPa

Connection Method

Flange Connection

Product Name

Air Bellow

Transport Package

Wooden Case

Specification

Make to order

Trademark

SUN HONG

Origin

China

HS Code

8439990000

Product Description

Product DescriptionThe air spring is located in different areas of the paper production process. Air springs consist of a flexible elastomer rubber body with nylon fabric reinforcement, and rustproof plates with an air inlet and mounting blind nuts. The rubber bellows can be used both as vibration isolators and rubber actuators. The air springs absorb up to 99% of the unwanted vibrations avoiding further damages to the machines and metallic structures. At the same time, they reduce noise level. Application

The Air springs are applied in different kind of applications in paper mills, where we can see the different functions that the air actuator provides in different parts of the paper manufacturing process:

1.Air spring used as an edge control system to align the bandage that carries the paper.

2.Tenses the web that carries out the paper.

3.Used as a press, to extract the humidity from the paper with the rollers located in the machine.

Principle

One requirement of air springs for paper machine is shock absorption and the other is stroke control.

By adjusting the compressed air pressure into the air spring, the height of the air spring decreases, the volume of the inner chamber decreases, the stiffness of the spring increases, and the effective bearing area of the air column in the inner chamber increases, and the bearing capacity of the spring increases. When the vibration load decreases, the spring height increases, the cavity volume increases, the spring stiffness decreases, the effective bearing area of the air column decreases, and the bearing capacity of the spring decreases.

In this way, the height of air spring, the volume of inner cavity and the bearing capacity of air spring have smooth flexible transmission and high efficiency control of amplitude and vibration load with the increase and decrease of vibration load. The stiffness and bearing capacity of the spring can also be adjusted by increasing or decreasing the air charge.

Advantages

1.Lower cost;

2.Maintenance cost savings, no moving parts, no sealing parts, no friction between parts;

3.No mantenance or lubrication required;

4.Reduced space requirement;

5.Angular capability. Product Parameters

| SH80-01 | SH160-01 | SH400-01 | |||

| Maximum load | 88kg | Maximum load | 1251kg | Maximum load | 8958kg |

| Maximum Diameter | 80mm | Maximum Diameter | 175mm | Maximum Diameter | 430mm |

| Natural Diameter | 80mm | Natural Diameter | 160mm | Natural Diameter | 400mm |

| Minimum compression height | 40mm | Minimum compression height | 74mm | Minimum compression height | 82mm |

| Maximum elongation height | 70mm | Maximum elongation height | 190mm | Maximum elongation height | 247mm |

| Component weight | 0.1kg | Component weight | 1kg | Component weight | 4.9kg |

Our engineers are inspecting the finished air spring.

Sun Hong Group

Sun Hong Group is a company specializing in serving the pulp and paper industry by manufacturing quality equipment and provide technical support to help customers solve various problems in production. Our aimis to help our customer improve production efficiency and reduce energy consumption.

Own factory equipped with high-precision CNC machine tools and machining centers, advanced equipments and instruments, which can fully guarantee the stability and reliability of the products. There we can offer you the best quality at the most competitive prices.

>> Australia Double Glass Aluminum Door Double Tempered Glass Four Panels Aluminum Patio Slider Sliding Glass Door

>> MAICTOP car exterior accessories roof luggage roof rack for prado fj150 lc150 2018

>> Solar CCTV Camera Home Security WiFi Solar PTZ Camera Rechargeable Outdoor

>> Plisse Window Mesh Polyester Pleated Insect Screen Net for Retractable Window and Door Screen System Waterproof Mesh

>> battery powered residential water flow meters,smart water meter

>> Harvester Machine Mini Small Combine Harvester for Sale

>> Automatic Js2000 Ready Mix Concrete Mixer Factory Outlet

>> Hydraulic Filter 84239751 for VolvoTractor

>> Zipper Hoodies Design Hoodie Wholesale Unisex Quick Dry Autumn Spring Sports Wear Long Sleeve HOODIE

>> High Quality New Fashion Design Leather Jackets Slim Fit Motorcycle Zipper leather Jacket for men

>> Automatic Bottle Body &Cap Label Shrink Tunnel for POF FC

>> T11 3772010/020 Car T11 front head lamp cover Auto parts T11 front headlight cover for t11 chery tiggo

>> Kitchen Food Waste Crushing Mixing Compost Turner Machine for Organic Fertilizer

>> Professional Supply Customize Jacquard Interlock Seamless 64% Nylon 36% Spandex Fabric for Underwear

>> Superior Quality Automatic High Speed Busduct Inspection Machine with Exquisite Workmanship

>> European and German Design Thermal Break Aluminum Inward Opening Tilt-and-Turn Window with Steel Mesh

>> car spare parts 42200-SM4-J51 rear axle wheel hub bearing for honda accord

>> Youth Cold Weather Outerwear with Custom Logo and Tailored Fit

>> Precision Parts Stainless Steel Mold Stamping Sheet Metal SPCC Part

>> High Performance Rectangle Stepped Permanent Magnet T-Shaped Magnet

>> High Quality Artificial 5 Branches PU Tulip Bridal Bouquet Flowers Real Touch Tulips for Wedding Hotel Decoration

>> China Remote Control Door Opener

>> China Brand New 2024 Sinotruck HOWO 6X4 10m3 Diesel Cement Truck Concrete Mixer Truck with Drum

>> Tongbo Small Gasoline Super Quiet Fuel Efficient 2kw 2kVA 2.5kVA 3kVA 4kVA 5kVA Portable Petrol Inverter Generator

>> High Quality Pet Lid Jar Wide Mouth Food Container Making Machine

>> Long Lasting Mini LED Bulbs 5W 7W G4 G9 Bi Pin Plug Lamp SMD LED Bulb

>> 100% Natural Bamboo Scrub Brush Pot Brushes Dish Scrubber for Household Cleaning

>> Modern design stretch ceiling flattened aluminum expanded metal

>> New Hydraulic Pressure Brick Block Machine Qp600

>> Yuyun Sanhe Centrifugal Push-Pull Type Exhaust Fan AC Axial Flow Fans for Agricultural Greenhouse Ventilation Cooling System Poultry Farm Livestock Equipment