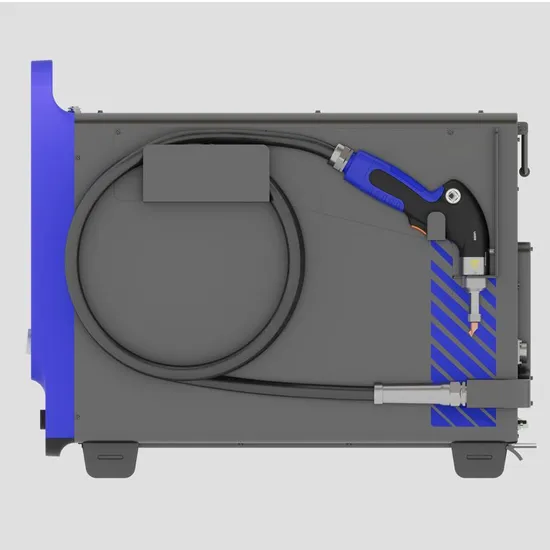

2025 HS-Laser 2000W Handheld Refrigerant Fiber Laser Welding Machine for Metal Welding

| US$6,500.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

HS-HW2000

Application

Biomedicine, Electronic Industry, Automotive Industry, Powder Metallurgy, Manufacturing Industry

Technical Class

Continuous Wave Laser

Control

Manual

Power Density

Deep Fusion Welding

Laser Classification

Optical Fiber Laser

Type

Portable Welding Machine

Laser Source Brat

Strongest

Weight(Kg)

45kg

Key Selling Point

Easy to Operate

Brand Name

HS Laser

Wavelength

1064

Focal Spot Diameter

120

Function

Metal Welding Service

Laser Type

Fiber Laser

Power Supply

220V 50Hz/60Hz

Cooling Method

Air Cooling

Transport Package

Wooden Box

Specification

670*505*310mm

Trademark

Hs Laser

Origin

China

Product Description

Dual circuit refrigerant laser welding machine1200W 1500W 2000W 2500W1. Experienced MIG and TIG users benefit from the faster, more flexible processing capabilities of fiber handheld laser welders;

2. Easy to learn and operate with the highest process consistency;

3. High-quality welding of thick, thin and reflective metals without distortion, deformation, undercut or burn-through;

4. Welding of dissimilar metal parts of different thicknesses;

5. Very low heat input with minimized heat-affected zone;

6. Minimal grinding or polishing for part setup and post-processing;

7. Increased productivity without machining or straightening of deformed parts.

| Item | HS-HW1200 | HS-HW1500 | HS-HW2000 | HS-HW2500 | |

| Rated input power supply | Single phase 220V | ||||

| Input power frequency | 50/60HZ | ||||

| Laser Power | 1200W | 1500W | 2000W | 2500W | |

| Guide Beam | Class 1 Red Guide Beam | ||||

| Laser Type (Welding mode) | Ytterbium Continuous Wave 1070 nm Fiber Laser | ||||

| Wave length | 1080nm | ||||

| Spot Size | 30μm | 14μm | |||

| Wobble Length | 5mm | ||||

| Cooling | Dual-circuit refrigerant direct cooling | ||||

| Weld penetration (Single side) | Aluminum | 1.5-2mm | <3mm | <4mm | <=5mm |

| Stainless Steel | 0.2~2.8mm | <3mm | <4mm | <=6mm | |

| Carbon Steel | 0.2~2.8mm | <3mm | <4mm | <=6mm | |

| Galvanized Sheet | 0.2~2.4mm | <3mm | <4mm | <=6mm | |

| Brass | <2mm | <2mm | <2mm | <=3mm | |

| Mild Steel | 0.2~2.8mm | <3mm | <4mm | <=6mm | |

| Process Gas | Argon, Nitrogen, Helium, compressed air | ||||

| Applicable Wire diameter | 0.8/1/1.2mm | 0.8/1/1.2/1.4/1.6mm | |||

| Safety | Class 4 Laser Device Customer responsible for standard ANSI Z136.1 safety precautions. System features include key for laser ON/Off, 2-step laser operation trigger (Enable and Fire), Part-head contact safety circuit, Facility door interlock circuit. | ||||

Weld Samples

>> Socks Shoes Slip on Fuzzy House Long Sock Warm Plush Bedroom Shoes

>> Emvh Co-Injection Series Injection Molding Machine

>> Outdoor Exterior Anti Slip Courtyard 600X600 Matt Floor Wood 2cm Thick Anti-Frost Paving Tiles Price for External Courtyard

>> Silicone Bracelet Laser Marking CO2 Laser Marking Machine, Silicone Bracelet Customize Service 30W 50W

>> Weco Light Curtain for Cargo Elevator 11mm Thickness Centeral Opening

>> Polyester Elastane T-Shirt Fabric

>> Ws-C Series 150L-400L Horizontal Cylindrical Pressure Steam Sterilizer Autoclave

>> Universal Application Steering Wheel Spacer Forged Al6061-T6 with CNC Machine Finished

>> 2024 Portable Handheld Mini USB Rechargeable Fan

>> Automatic Euro Wood Pallet Pier Connecting Nailing Machine for Linking Foot Pier

>> OEM ODM Factory Frameo APP 15.6 Inch Frame Share Photos Videos Digital Photo Picture Frames with Touch Screen

>> Bamboo Bread Box Creative Design Nordic Kitchen Bamboo Fiber Storage Box Pantry Organizer Kitchen & Tabletop

>> 80X80mm Thermal Receipt Paper Roll for ATM/POS Paper Roll

>> TRICONEX 4210

>> Aluminium Sliding Door Pictures from aluminium double glazed windows & doors

>> Aluminum Alloy Die Casting ODM Zinc Alloy Die Casting

>> 1000 Liters Per Hour Purification System RO Filtration Treatment Plant Water Purifying Machine

>> Auto Body Parts Car Body Kit For Camry Accessories 2018 2019 SE

>> China High Quality Popular Cheap Crawler Excavator

>> Automatic Pre-Made Pouch Zipper Bag Doy Bag Packaging Machine for Pet Food, Coffee Bean, Candy, Chips with Factory Price

>> Engraver and Cutting Machine A2-1325-PRO CNC Router for Furniture Industry

>> HONGEY GINGER TEA Arabic Halal

>> Hot Sale Double Glass Panels Frame Fixed Glass Aluminum Casement Windows

>> Yingzoom Cheap Universal Joint Ball Cage Outer Surface Grinding Machines

>> Minimalist ladies wristwatch Skmei 1410 simple design top quality waterproof women watch for small wrist

>> Seaweed Removal River Water Weed Garbage Hyacinth Harvester

>> Stylish Fashion Best Quality Round Shape Genuine Leather Women Handbag

>> Hot Selling Rechargeable COB LED Portable Work Light for Camping USB Rechargeable Mini COB Work Light Keychain LED Flashlight 80

>> Taijia Concrete Rebar Detector Locator Scanner ZBLR800 Integrated Rebar Locator Rebar Corrosion scanner

>> custom printed foil laminated mylar ziplock bags from china