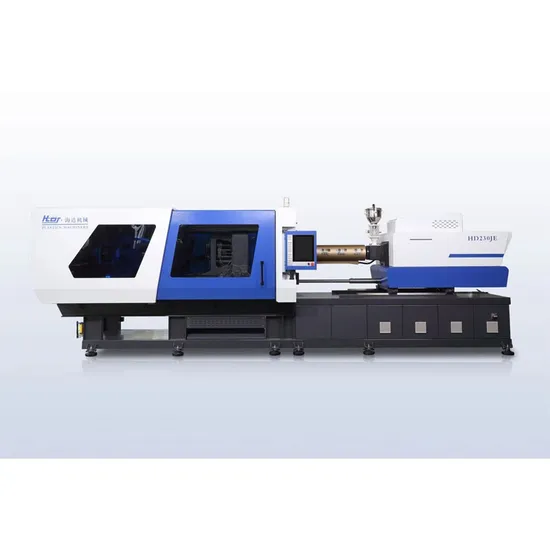

Haida HD230je All-Electric Injection Molding Machine

| US$80,000.00-90,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

HD230JE

Type

Injection Molding Machine

Structure

Horizontal

Plastic Type

Thermoplastic

Plasticizing Way

Screw Type

Clamping Way

Hydraulic

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008, GMP, QS

Selling Point

High Precision Energy-Saving

Delivery Date

30days

MOQ

1set

Plastic Processed

PP, PC, ABS, Pet, PVC, FRPP/PVC, PPR, HDPE, Mlldpe

Core Components

Bearing, Motor, Pressure Vessel

Transport Package

Wooden Pallet

Specification

230T

Trademark

HAIDA

Origin

Ningbo

HS Code

8477101090

Production Capacity

1000sets/Year

Product Description

Product DescriptionHDJE Full-Electric Series:

Mode locking unit>>Optimizing the performance of the clamping mechanism, reducing the inertia of the movement, opening and closing the mould quickly, smoothly and without vibration, to meet the demand of opening the mould for precision products;. The moving die supports the heavy die slide block to reduce the friction coefficient.

______________________________________________________________________________________________________________________ Injection unit>>Low coefficient of friction injection structure, rapid precision injection molding, the fastest speed up to 500 mm/s.

______________________________________________________________________________________________________________________ Servo Drive system>> By matching the servo motor and the servo drive reasonably, the driving efficiency is further improved, the high precision and high response are realized, and the energy consumption of the whole machine is further reduced.

______________________________________________________________________________________________________________________

Precision&Environmental Protection and energy conservation>> The pressure is controlled at 0.1 mpa, the position is controlled at 0.01 mm, the speed is accurate to 0.1 mm/s, the repeated positioning accuracy is high, and the product quality is guaranteed.

Driven by servo motor, low noise, bring customers a clean production environment. Compared with the traditional injection molding machine electricity saving 25%-80% , water saving 80-90% .

______________________________________________________________________________________________________________________

Basic Information:

| Number Item |

| HD230JE |

| Category |

| HDJE Series |

| OEM |

| Available |

| Warranty |

| 1 Year |

| Factory |

| Yes |

| Model NO | HD230JE | Computerized | Computerized | |

| Certification | CE, ISO9001:2008 | Plastic Processed | PP, PC, ABS, PET, PVC, FRPP/PVC, PPR, EVA, HDPE, MLLD | |

| Style | Horizontal | Packaging Details | wooden pallet | |

| Plastic Type | Thermoplastic | Machine Type | Hybrid(Eletric for injection parts,Hydraulic for clamping parts) | |

| Condition | New | Energy Saving | Servo Energy Saving | |

| Brand Name | Haida | Production Capacity | 100 Set/Sets per Month | |

| After-sales Service Provided | Engineers available to service machinery overseas | Warranty of core components | 1 year | |

| Place of Origin | Zhejiang,Ningbo,China | Local Service Location | Viet Nam, Brazil, Thailand, South Africa, Uzbekistan |

Detailed Photos

HDJE series aims to achieve high injection moulding repetition rate and high productivity.With stable and reliable injection mechanism,professional screw barrel plasticizer,high precision temperature field closed loop control,high rigidity clamping mechanism,servo motor and servo drive matching reasonable optimization,to ensure the repeated precision of plastic products,production efficiency significantly improved.

_

_______________________________________________________________________________________________________________________________________

Product Parameters

| ITEM | MODEL | HD230JE | ||

| CLAMPING UNIT | ||||

| CLAMPING FORCE | KN | 2300 | ||

| OPENING STROKE | MM | 550 | ||

| SPACE BETWEEN TIE-BARS | MM | 620*620 | ||

| MOLD THICKNESS(MIN-MAX) | MM | 220-600 | ||

| EJECTOR STROKE | MM | 150 | ||

| EJECTOR FORCE | KN | 49 | ||

| INJECTION UNIT | A | B | ||

| SCREW DIAMETER | MM | 40 | 45 | |

| SCREW L/D RATIO | L/D | 21 | 24 | |

| INJECTION VOLUME | CM3 | 282 | 358 | |

| SHOT WEIGHT | G | 257 | 326 | |

| INJECTION RATE(PS) | G/S | 439 | 506 | |

| INJECTION PRESSURE | Mpa | 280 | 220 | |

| SCREW RPM | RPM | 350 | ||

| INJECTION SPPED(MAX) | Mm/s | 350 | ||

| OTHERS | ||||

| MOTOR POWER | Kw | 107 | ||

| HEATER POWER | Kw | 20 | ||

| MACHINE DIMENSION | m | 6.9x1.9x2.2 | ||

| MACHINE WEIGHT | t | 12.8 | ||

| MOLD ORIENTATION RING | mm | 125 | ||

| NOZZLE RADIUS | mm | SR10 | ||

Application

APPLICATION FIELD:

HAIDA Full-electric widely used in food packaging,medical equipment,auto parts,communications,electronic appliances,instrumentation and other fields.

Auxiliary Machines

Company Profile

HAIDA MACHINERY established in the year 1991 at Ningbo, is one of THE TOP 10 CHINESE injection molding machinery manufacturer. Nearly 30 years, we had established more than 60 sales and service agencies in China and overseas.

We are manufacturing different types of injection molding machines and range starts from 50 Ton to 3300 Ton.

We committed to providing the complete solutions for Plastic. Our name involved in manufacturing and supplying a flawless quality range.

Packaging & Shipping

Exhibition and others

>> 304 Stainless Tube Shields

>> Oval Rail Personnel Access Panel / Penal Gate

>> Wholesale Good Quality Red Kid Scooter 2024 Toy Scooter Kids

>> PVC Film for Lvt / Wear Layer Waterproof /Antiwear Floor 0.30mm

>> Made in China Tg Food Grade Alll SUS304 Bubble Tea Automatic Boba Pearl Machine Production Line

>> Manufacturer Promotion Sports Arm Sleeves Cycling UV Protection Sleeve Cover Summer Nylon Seamless Ice Sleeves

>> Scaffold Frame| 3'X6'8" | WALK THRU walk through scaffolding supplier

>> Bathroom Supplies Biodegradable Luxury Hotel Amenities Mini Shampoo Bottle Hotel Amenities

>> custom barbijos facemask kn95 paper packaging box

>> Belyoo Mobile Hotdog Taco BBQ Snack Catering Cart Vending Van with Kitchen Equipment Ice Cream Machine Mobile Truck Food Trailer for Sale

>> Fully Automatic Recycled Plastic PP PE Recycling Machine Washing Line

>> 2022 New Design Tracksuit Yoga Sports Wear Suit Training Wear men Joggingsuit Jogging

>> Auto Body Parts S Class W221 Front Bumper Lower Grille Vent 2218851722

>> Synthetic Silicone Rubberhot Air Duct

>> 4yz-4SL Self-Propelled Corn Combine Harvester Farm Machine with 160HP 4rows Luxury Cabin.

>> 2021 New Crop Green Chili

>> High Power Ultrasonic Sewing Machine Rotary Welding Seamless Sewing Machine

>> Garlic Potato Harvester Tools Potato Collecting Harvester Potato Harvester Machine

>> Customizable Outdoor Wood Storage Fireplace Stove and Log Rack

>> Xiantao Xingrong Disposable Nonwoven Doctor Cap PP Cap

>> Copper Brazed Plate Heat Exchanger for Solar Water Heating System

>> Best Price Monoblock Miter Cut Granite Bridge Saw Automatic Stone Cutting Machine

>> High Precision Industrial Drill Press 20mm (Z4120)

>> Double Shaft Scrap Copper Wire Recycling Electrical Copper Cable Iron Steel Metal Cans Shredder Recycling Machine

>> AS2047 label Sound insulation Energy saving double glazed aluminium tilt and turn window

>> Schuko Europe Plug Insert with Hollow Pins

>> Chinese Factory Micro Digger 0.8 Ton Kubota Crawler Excavator

>> Sanitary Ware PVD Brushed Gun Metal H59 Brass Bathrooms Sink Faucet

>> Mining Excavator Part 21n-26-00120 Swing Device PC1250-8 Swing Gearbox

>> High Speed Mixer for PP PE Mixing and Coloring