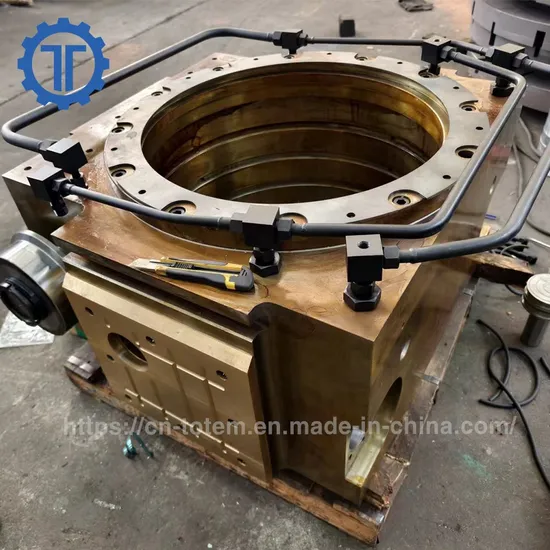

Totem 40cr Forging Bearing Seat, Bearing Block, Roll Chocks for Rolling Mill

| US$1,688.00-2,888.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

large

Feature

Corrosion Resistant

Material

Cast Iron

Bearing Block Model

Customized

Housing Material3

40cr

Bearing Material

Babbitt

Bearing Material4

SAE 11 Alloy

Bearing Material5

SAE 13 Alloy

Bearing Material2

White Metal

Bearing Material3

Rematal

Housing Material

Cast Iron D1

Housing Material1

Cast Steel Zg25

Housing Material2

Cast Steel Zg35

Trademark

Totem

Origin

China

HS Code

8483200000

Packaging & Delivery

Package Size

180.00cm * 160.00cm * 90.00cm

Package Gross Weight

300.000kg

Product Description

Product DescriptionZG35CrMo Rolling Mill Steel Forging Large Work Roll Bearing Housing

Bearing Housing Mill Housing uses on steel factory for steel rolling mill.

Bearing Housing Mill Housing Processing

Bearing and housing drawing CHECK, Confirm Material Make casting Mold, casting Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

Bearing Material

Bearing--- Babbitt SAE 11/13 Alloy, White metal, Remetal, Customized material

Housing Material

Housing--- Cast steel (40Cr / ZG 25/ ZG35), Casting iron (D1), Customized material

Bearing Housing Package

Spray anti-rust oil on babbitted bearing, Wrap waterproof cloth around, Prepare anti-corrosion package or wooden box etc.

We can manufacture different tpye of bearing housing/chock according to drawing

TOTEM Machinery locates on Pudong district, Shanghai city.

We focus on supplying bearing seat more than 10 years.

Our bearing housings mainly use on both sides of shaft to support and fix bearing. Which is a key part of steel rolling mill's work roller.

TOTEM can provide forging and casting two types options of bearing block.

Forging type bearing block is durable and wear-resistant.

Casting type bearing seat is economical and stable.

Looking forward to your inquiry and visiting to SHANGHAI TOTEM.

Detailed Photos

Production Process

1. Material--Large OEM metallurgical bearing housing/block/chock can be produced by forging or casting.Common used material is 35CrMo,42CrMo,casting gray Iron, ductile iron, chrome bearing steel GCr15 or other customized material.

2.CNC machining Bearing housing/block/chock is produced by precision CNC machining to guarantee it's tolerances and accuracy.

3.Milling machine for hole millingDetermine the technical requirements for holes, including dimensional accuracy, shape accuracy, positional accuracy, and surface roughness of the holes. These requirements are crucial for ensuring the performance and service life of the bearing seatPackaging & Shipping

Other Related Products

Company Profile

TOTEM PRODUCTsForging parts, Casting parts and Machining parts and Welding parts. Mainly use on Hydraulic Forging Press, Rolling Mill Production Line, Mining Plant, Cement plant, Power Plant, Oil Field, Seaport Facilities, Paper Mill Plant, Vessel etc. (More details, please view our website on Made-in- China: https://cn-totem.en.made-in-china.com)

We have different specifications of oil forging presses,ring rolling machines,electric arc furnaces,thus we can provide variety of forging,casting and welding materials according to customer's requests.- Large capacity, completed variety of quenching medium: oil,water,salt water,water based mixture.

Advantage of our Heat Treatment:- Professional, specific furnace, single-minded- Vertical pit furnace,keep the temperature uniformity during heating,+/-1°- Small deformation,little oxide layer,reduce material cost- Different materials can be cooled at the best speed

Strictly quality inspection system can produce high quality products. For each order,we can provide report for material chemical components testing,UT testing, hardness, mechanical property testing(impact testing,yield strength testing,tensile strength testing),size inspection,etc.

Our products have been exported to abroad for more than 10 years and 50+ countries,such as America,Australia,Russia,Pakistan,Thailand,Indian,Morocco,Romania,Spain,etc.

In order to avoid the finish products rusted and damaged during the transportation ,we will design the right packing according to the shape,size and usage of the products.FAQ

What's TOTEM product processing progress?Drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing. How about TOTEM's export package?

Spray anti-rust oil on Herringbone Gear Shaft, Wrap waterproof cloth around Gear Shaft for reducer, Prepare package by shaft shape&weight to choose steel frame, steel support or wooden box etc.Could I customize gear\gear shaft on TOTEM?

We supply customized Gear Shaft,Eccentric Shaft,Herringbone Gear,Internal Gear,Bevel Gear with big module, more than 1tons big weight, more than 3m length, forging or casting 42CrMo/35CrMo or your specified required material. Why can I choose TOTEM?

TOTEM has 24hrs Salesman on-line, guarantee quick and positive feedback.TOTEM Machinery invests and becomes shareholders of several machine processing factories, forging factories, casting factories, relies on these strong reliable and high-quality supplier's network, to let customers worry-free purchase.Experienced and Professional Forwarder Guarantee Log. transportation.

>> bending sheet metal fabrication decorative custom perforated sheet metal

>> Pet Products Wholesale Cat Litter Natural and Eco-Friendly 6L Tofu Cat Litter Clumping Cat Sand Fabricado En China Eco Cat Litter

>> Ek25 Household Multifunction 5kg 3kg Electronic Smart Weighing Digital Kitchen Food Weight Scales

>> CE Approved DIN Surely Standard Packaging or Customized Stainless Steel Aluminum Die Casting

>> Diesel Electric Bakery Convection Furnace for Meat, Bread, Cake, Biscuits

>> Wholesale Professional High Light Straight Cold Fusion Double Drawn I Tip Human Hair Extensions

>> Outdoor bicycle Waterproof Hydration Backpack for 2L Hydration Bladder

>> Clamp Car Customized Aluminum Cnc Sheet Metal Stamping Parts

>> Stylish and Budget-Friendly Aluminum Photo Frames for Every Occasion

>> Woman Tote Bag Ladies Handbag Fashion Desinger Leather Shoulder Bag Custom Lady Handbag

>> TRICONEX 2101

>> Puff Snacks Food Making Machines Corn Puff Snack Extruder Snack Food Production Line

>> Custom Logo Pink Vegan Creamy Matte Lipliner Brown Nude Twist up Lip Liner Pencil

>> Professional Manufacturer Bathroom Basin Kitchen Sink Faucet Water Tap Faucet Bath Shower Mixer Bathroom Accessories Plumbing Fixtures

>> Hy300 PRO Smart Portable Projector Android 13 Dual WiFi LCD Video 1080P Home Theater Game Projector 4K Mini Projectors

>> Chtools Factory Hot Products Broach Cutter Magnetic Drill Machine

>> Disposable Clear Plastic Graduated 0.2ml Micro Centrifuge Tubes with Attached Lid for Laboratory

>> Sell Luxury industrial rice cooker machine

>> auto electric power tailgate for bmw 5 series g30 automatic tailgate opener electric tail gate lift

>> Hot Selling Portable Mobile Printer Thermal Receipt Printer for Thermal Paper

>> in-Ear Noodle Headset Silicone Cap Manufacturer. Transparent Silicone Large, Medium and Small Ear Hook

>> Professional Manufacturer Wholesale Good Quality Black Mini Buffer 10Mm Air Cushion Pillow Packaging Bubble Film Making Machine

>> 10W RGBW 4in1 Pin Spot Mini LED Club Party Light

>> Chinese Frozen French Fries Potato French Fries Potatoes OEM Factory with Halal

>> Commercial Automatic Fast Color Change Easy Cleaning PP Powder Coating Spray Booth

>> High efficiency heavy duty rock trommel screen mining trommel screen for energy ore

>> Ultrasonic humidifier

>> Foreign Trade Explosion Models Summer 2020 Flat Bottom Wild Fashion Open Toe Women Shoes Fashion Sandals

>> Windproof Stable Comfortable Durable Summer Dry Cooler Horse Rug

>> 2 Ports 8 Scales Real Down Fake Down Jacket Peal Cotton Parker Winter Jacket Weighing Filling Stuffing Machine