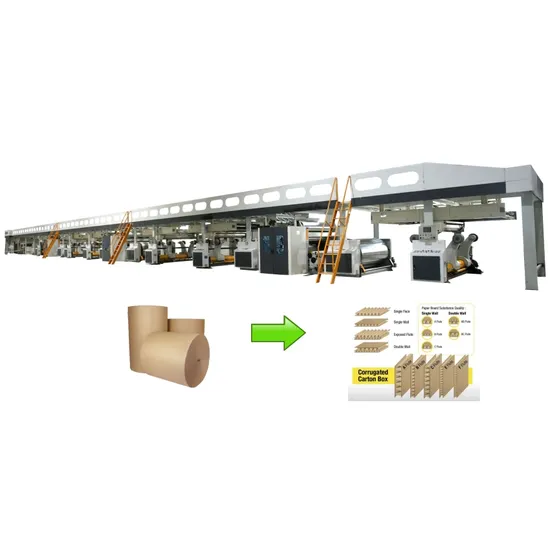

Qh Pack High Speed Corrugated Cardboard Production Line Make Machine

Basic Info.

Model NO.

1800

Condition

New

Certification

ISO 9001:2008, CE

Automation

Automatic

Suitable for

Paper

Paper Thickness

Normal Specification Paper

Product Name

Corrugated Cardboard Production Line

Speed

60-80m/Min

Other Name

3ply Corrugated Line

Function

Corrugated Cardboard

Transport Package

Film Packaging

Trademark

QH pack

Origin

Cangzhou City, Hebei Province

HS Code

84393000

Product Description

Product Description WJ100-1800-3PLY CORRUGATED CARDBOARD PRODUCTION LINE CONFIGURATION LIST| No. | Name | Qty | Feature | |

| 1 | RS Electrical Mill Roll Stand () ( with trolley and track) | 3 | ,,,, --Toothed chuck,manual discbrakes,pneumatic mechanically actuated lift,panning left and right on the middle 4500mm,10mm --Guide rail length is 4500 mm, the trolley adopt 10 mm plate welding | |

| 2 | PH-60 Pre-heater | 2 | φ600mm;,360° --The roller φ600 mm,Electric adjustment angle,adjusting heating area within the range of 360 ° | |

| 3 | SF-10A(280) Single Facer | 1 | φ280mm,48CrMo,;,;;,; --Corrugated rollerφ280mm, 48CrMo high quality alloy steel,plating chromed --Independent gearbox,universal joint drive structure --Cylinder control lifting --Pneumatic control glue,circulating supply glue | |

| 4 | OB Conveying Bridge | 1 | 20063;;, --The main beam is connected with the GB 200 channel steel,63 angle steel --Independent frequency motor drive paper conveying --Suction tension and electric correcting | |

| 5 | Duplex Pre-heater | 1 | φ600mm;,360° --The rollerφ600 mm,electric adjustment angle angle,adjusting heating area within the range of 360 ° | |

| 6 | GM-15 Glue Machine | 1 | φ269mm,25;;;,PLC; --Glue roller φ269mm,carved 25 line pit type mesh --With preheater device --Independent frequency motor drive --Circulating supply glue with PLC control --Man-machine interface display | |

| 7 | DF-40 Double Facer | 1 | 360 mm ;600 mm *9;4;,;; --Main frame is 360 mm GB channel steel --Hot plate 600 mm 9 pics with plating chrome; --4 M cooling section --Adopt pressure bar lifting by pneumatic control --The upper belt correct automatically --Frequency motor drive | |

| 8 | SS-E Electric Blade Machine | 1 | ,200mm;;;;58 --Blade adopt tungsten alloy steel,φ200mm --Electric adjusting and correcting --Automatically grinding --Manual adjust the scorer --5 blade 8 line | |

| 9 | NC Cut-Off(Straight) | 1 | ;;;;10.4 --Full AC servo control --Energy storage type braking --Straight knife structure --Oil-immersed gear transmission --10.4-inch touch screen display | |

| 10 | LS Sheet Delivery Machine | 1 | ;;200mm --Electrical adjust the size of cardboard --Cardboard transverse output controlled by pneumatic; --Max stacking height 200mm | |

| 11 | Glue Making System | 1 | ;,,,, --Customers supply the pipeline --The glue making device includes: carrier tank,main body tank,storage tank,glue feeding pump and returning pump | |

| 12 | Internal Steam System | 1 | :,,,; --Steam system components adopt GB valve: Contains rotary joint,up and down distributor ,drain valve and pressure gauge, etc --Boiler and pipeline supply by customer | |

| Notes:(This price isn't included the installation charge) 2. Delivery: 120-150days after receiving the deposit 3. Payment: 30% down payment by T/T and 70% by T/T before shipment 4.Installation and training: Buyer need to be bound for the round trip flight tickets, cost for accommodation,and each engineer for $300 USD/day for salary) 5. Guarantee: 12 months | ||||

Packaging & Shipping

>> CNC Angle Steel Heel Cleaning Machine with High Speed

>> Super Fine Cement Powder Mill Grinding Ball Mill with Classifying Production Line

>> Thickness 3, 5, 8, 10mm Soft Graphite Felts for The Thermal Insulation

>> China 30 Million Gypsum Board Machinery Manufacture Automatic Production Line

>> Good quality blue disposable nurse cap OEM accepted Bouffant Mob Clip Cap

>> Floating Aquatic Plants Cutting Machine Water Hyacinth Harvester for Selling

>> 2020 Lvt/Spc Rubber Vinyl PVC Plank Plastic Gym Flooring Tile Cutting Machine

>> Braided Basket PP PE Plastic Artificial Rattan Wicker Making Machine

>> Large Delivery Backpack Cooler Lunch Thermal Insulated Food Delivery Bag Delivery Bag

>> Johsun Tec Mvr-10000va AC Relay Type Voltage Regulator Analog Meter Voltage Stabilizer

>> 2020 Crop Middle East Top Quality Small Packing Fresh Garlic

>> GPRS WiFi NFC Biometric Fingerprint Time Attendance with Android System

>> Dairy Farm Livestock Machinery Agricultural Machinery Cow Cubicle

>> High Quality Lathe Centre Vertical Lathe CNC Motorcycle Boring Machine Tool

>> Retractable Badge Reels Clips Ski Pass ID Card Badge Holder

>> High-Efficiency Stainless Steel Double Cone Mixer for Medicine Powder

>> Kg19041 465. Trw. 23 1419126001 Power Steering Pump for Zf Trw Freightliner Cascadia

>> Entertainment Center Standard Electronic Indoor Bowling Machine Bowling Alley Equipment Bowling String Pinsetter Machine

>> TM-8812 Metal Thickness Measuring Gauge Magnetic Thickness Gauge

>> Powder Production Line Mixing Machine Food Additives Production Line

>> Portable home use picosecond laser tattoo removal pico pen

>> ASME/PED Titanium/Zirconium/Tantalum/Nickel/Super Stainless Steel/ Welded Pipe

>> Flat profile steel grating

>> 1-10000L Stainless Steel Tank Mixing Tank Grinding Barrel Stirring

>> X5330B Radial Universal Milling Machine

>> Natural white offset paper 157g

>> High Quality Custom Electric Vacuum Cleaner Plastic Parts Mold

>> Luzhong high spindle speed metal X6330 turret milling machine fro sale

>> Physiotherapy Therapy Machine Extractorporeal Shockwave Therapy Machine Analog BS-Swt6000

>> Plastic 6 Oz Antistatic Alcohol Bottle Cleanroom ESD Alcohol Bottle Dispenser